Resolution colorimetric device and equipment

A colorimetric and lens technology, applied in the preparation of test samples, analysis by chemical reaction of materials, and material analysis by observing the influence of chemical indicators, etc., can solve the problem of inconsistent diameter, small processing difficulty, and digestion The volume of the cuvettes is large, and the effect of long optical path, high sensitivity and cost reduction can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

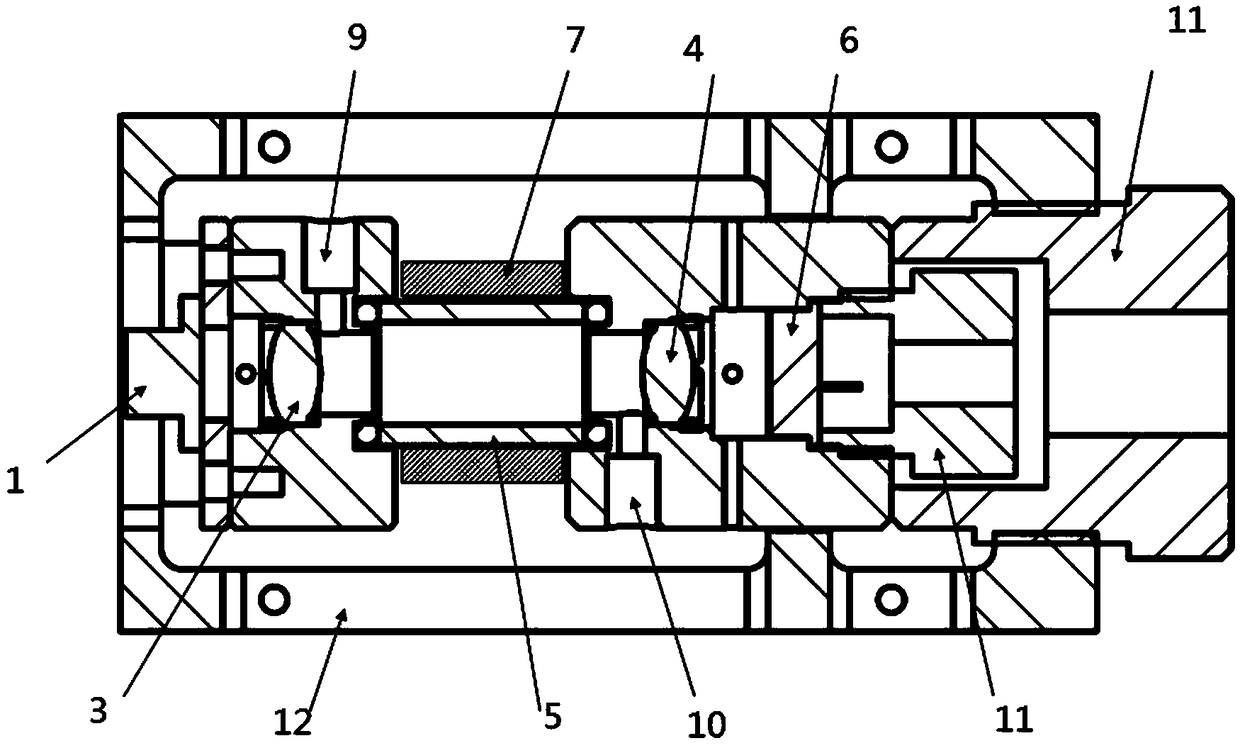

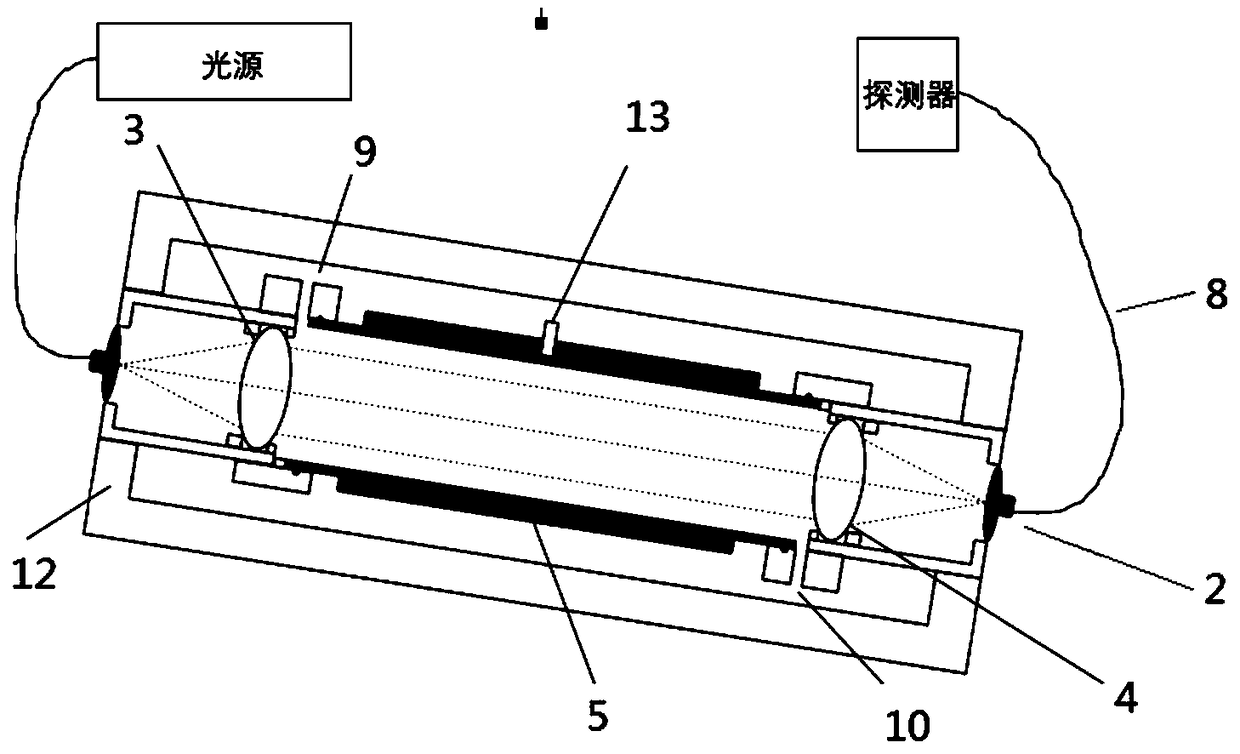

[0022] The embodiment of the present invention provides a kind of digestion colorimetric device and equipment, and the amount of reagent required in this embodiment is much smaller than that of existing market products (such as vertical tube structure). Realize variable and controllable optical path. The optical path can be changed only by changing the glass tube in the middle, and the sensitivity is high when the optical path is long. Controllability and maintainability of equipment.

[0023] The terms "first", "second", "third", "fourth", etc. (if any) in the description and claims of this application and the above drawings are used to distinguish similar objects and not necessarily Describe a particular order or sequence. It is to be understood that the terms so used are interchangeable under appropriate circumstances such that the embodiments described herein can be practiced in sequences other than those illustrated or described herein. Furthermore, the terms "comprisi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com