Method for testing recesses and dents on surface of automobile body

A technology for automobile body and surface depression, which is used in the test of elasticity, the test of machine/structural components, the use of stable tension/pressure to test the strength of materials, etc. It can solve the problems of permanent deformation, depression and deflection, etc. Safety, high degree of automation, and the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

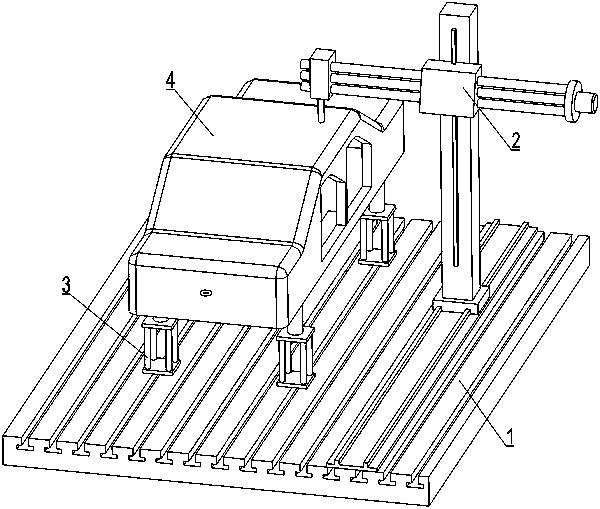

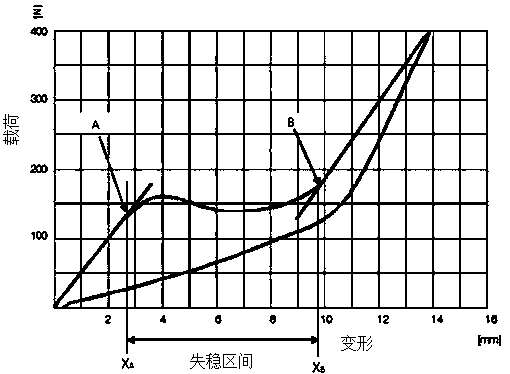

[0032] The invention discloses a method for testing the surface dent and dent of an automobile body. The test method is used for testing the dent resistance and local dent resistance of the surface of the automobile body after a new model is developed. This test method is based on the body static stiffness test bench to design a reasonable test plan for testing.

[0033] The invention discloses a test method for surface dents and dents of an automobile body, which is tested by using a body static stiffness test bench. The body static stiffness test bench includes a loading part and a data acquisition part, specifically including a servo-driven loading unit connected to the control board through a digital-analog output card, a displacement sensor and a force sensor connected to the control board through a digital-analog input card, A loading rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com