A Flexible Sheet Type Direct-Current Nozzle with Large Flow Range

A sheet-type, high-flow technology, which is applied to ramjet engines, combustion methods, lighting and heating equipment, etc., can solve the problems of limited flow range of single-channel fuel flow and cannot adapt to the requirements of engine fuel flow change range, etc., to achieve Improving performance and working stability, simple structure, and the effect of suppressing flow fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

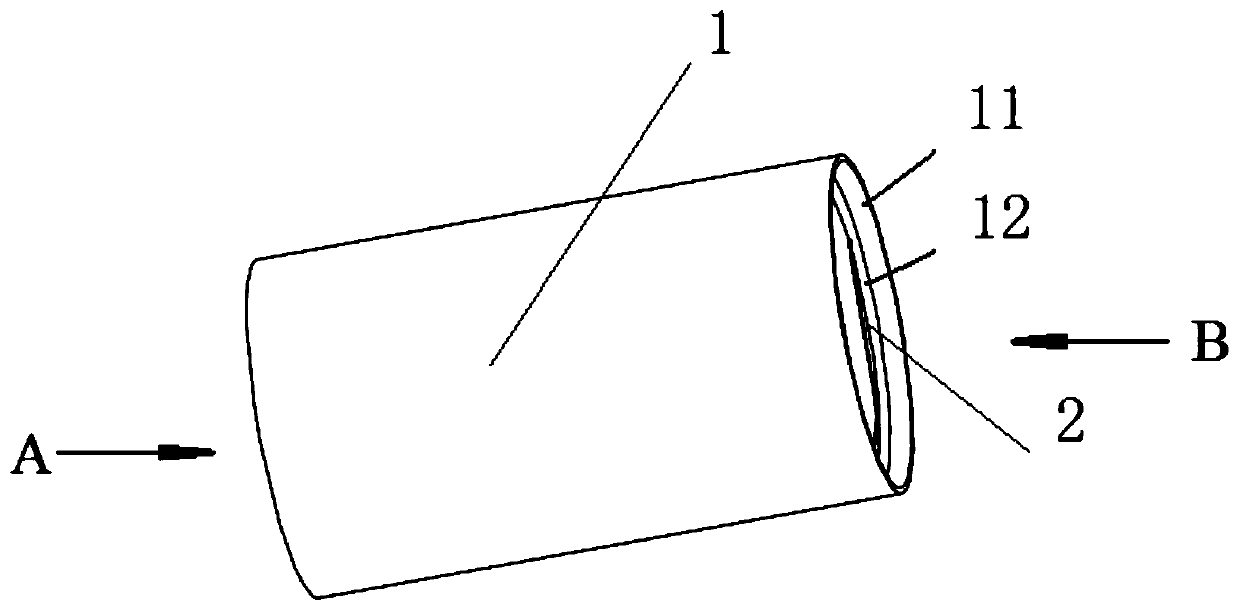

[0034] Such as figure 1 , figure 2 with image 3 As shown, the present embodiment provides a flexible sheet type DC nozzle with a large flow range, including a cylindrical nozzle body 1 with a circular cross section, one end of the nozzle body 1 is an opening, and the other end is fixedly arranged to completely cover the nozzle body 1 The flexible sheet 2 on the end face; the nozzle body 1 and the sheet 2 are made of spring steel.

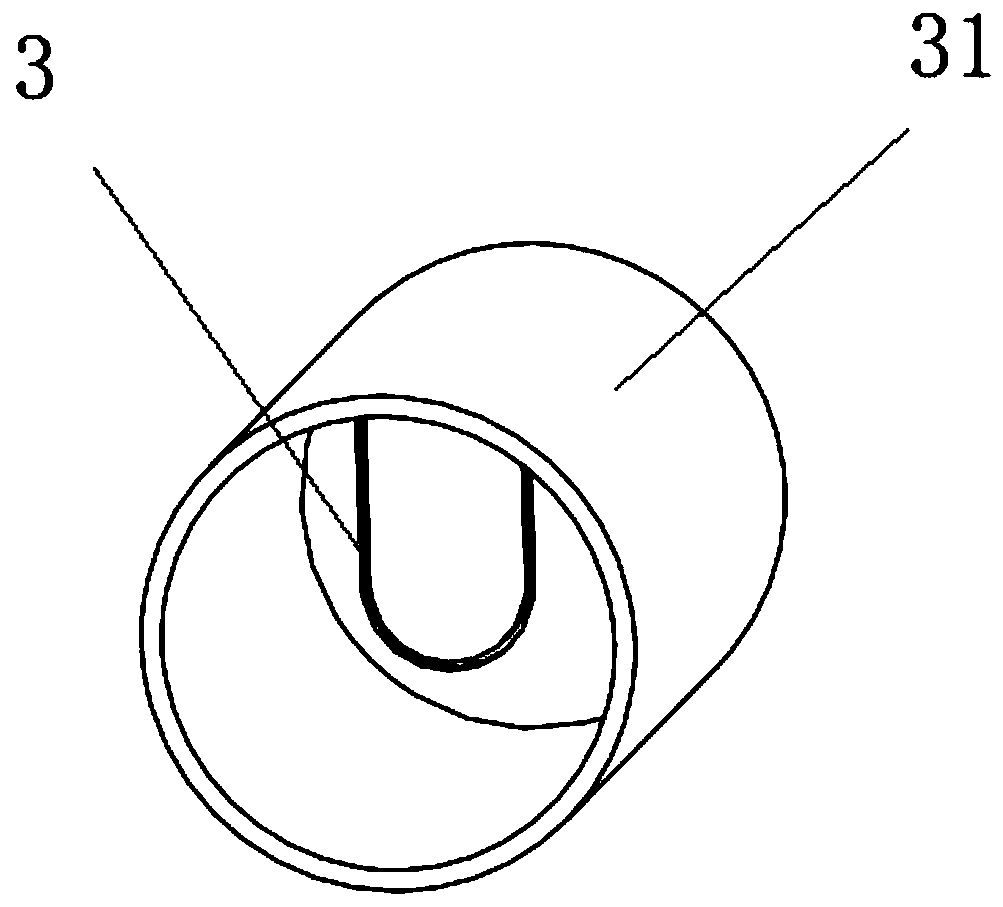

[0035] The thickness of the thickest part of the sheet 2 is 0.2 mm, and the thickness of the sheet 2 decreases linearly from the edge of the sheet 2 to the geometric center of the sheet 2 . An injection groove 3 for passing fuel is arranged on the sheet 2 .

[0036] The injection groove 3 is an S-shaped curve, and the injection groove 3 divides the slice 2 into two parts with the same semicircle shape, and each part of the slice 2 is in the shape of a cantilever.

[0037] The groove width of the injection groove 3 is 0.2 mm. Crack relief hole...

Embodiment 2

[0041] Such as Figure 4 , Figure 5 with Image 6 As shown, the present embodiment provides a flexible sheet type DC nozzle with a large flow range, including a cylindrical nozzle body 1 with a circular cross section, one end of the nozzle body 1 is an opening, and the other end is fixedly arranged to completely cover the nozzle body 1 The flexible sheet 2 on the end face; the nozzle body 1 and the sheet 2 are made of spring steel.

[0042] The thickness of the thickest part of the sheet 2 is 0.15 mm, and the thickness of the sheet 2 decreases linearly from the edge of the sheet 2 to the geometric center of the sheet 2 . Two injection grooves 3 for fuel passing are arranged on the sheet 2 .

[0043] The two injection grooves 3 intersect in a cross shape, and the intersection point is located at the geometric center of the sheet 2; the injection grooves 3 evenly divide the sheet 2 into four parts, and each part of the sheet 2 is in a cantilever shape. The groove width of t...

Embodiment 3

[0046] This embodiment provides a flexible sheet type DC nozzle (not shown) with a large flow range, which includes a cylindrical nozzle body 1 with a circular cross section. One end of the nozzle body 1 is an opening, and the other end is fixedly arranged to completely cover the nozzle. The flexible sheet 2 on the end face of the body 1; the materials of the nozzle body 1 and the sheet 2 are all spring steel.

[0047] The thickness of the thickest part of the sheet 2 is 0.3 mm, and the thickness of the sheet 2 decreases linearly from the edge of the sheet 2 to the geometric center of the sheet 2 . Four injection grooves 3 for the passage of fuel are arranged on the sheet 2 .

[0048] The four injection grooves 3 intersect to form a P-shaped shape, and the intersection point is located at the geometric center of the sheet 2 . The spout 3 evenly divides the slice 2 into eight parts, and each part of the slice 2 is in the shape of a cantilever. The groove width of the injectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com