Variable-diameter mechanism suitable for pipeline robot

A pipeline robot and coupling technology, applied in the direction of special pipes, pipe components, mechanical equipment, etc., can solve the problems of high manufacturing cost, small variable diameter range, complex mechanism, etc., and achieve simple structure, large variable diameter range, and mechanism good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

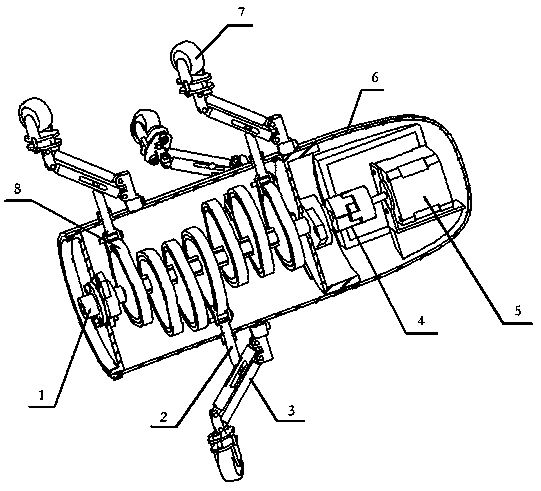

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

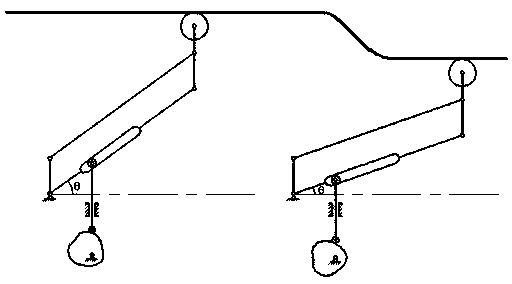

[0021] Such as figure 1 with figure 2 As shown, the present invention provides a novel diameter reducing mechanism suitable for pipeline robots.

[0022] by figure 1 Explain the variable diameter mechanism. The left side of the figure is the situation of the large diameter pipe, and the right side is the situation of the small diameter pipe.

[0023] The present invention comprises a main shaft 1, a cam push rod 2, a driving wheel frame 3, a coupling 4, a fixed seat 6, a motor 5, a traveling wheel 7 and a cam 8. Cam push rod 2 connects cam 8 and driving wheel frame 3, and road wheel 7 is installed on the end of driving wheel frame 3. The rotation of the cam 8 drives the extension and contraction of the driving wheel frame 3 through the cam push rod 2 to achieve the purpose of reducing the diameter.

[0024] Described cam 8 is fixed on the main sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com