A self-balancing throttle valve

A throttling valve and self-balancing technology, applied in balancing valves, valve devices, safety valves, etc., can solve problems such as poor adjustment accuracy, unstable throttle valve outlet pressure, and inflexible installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

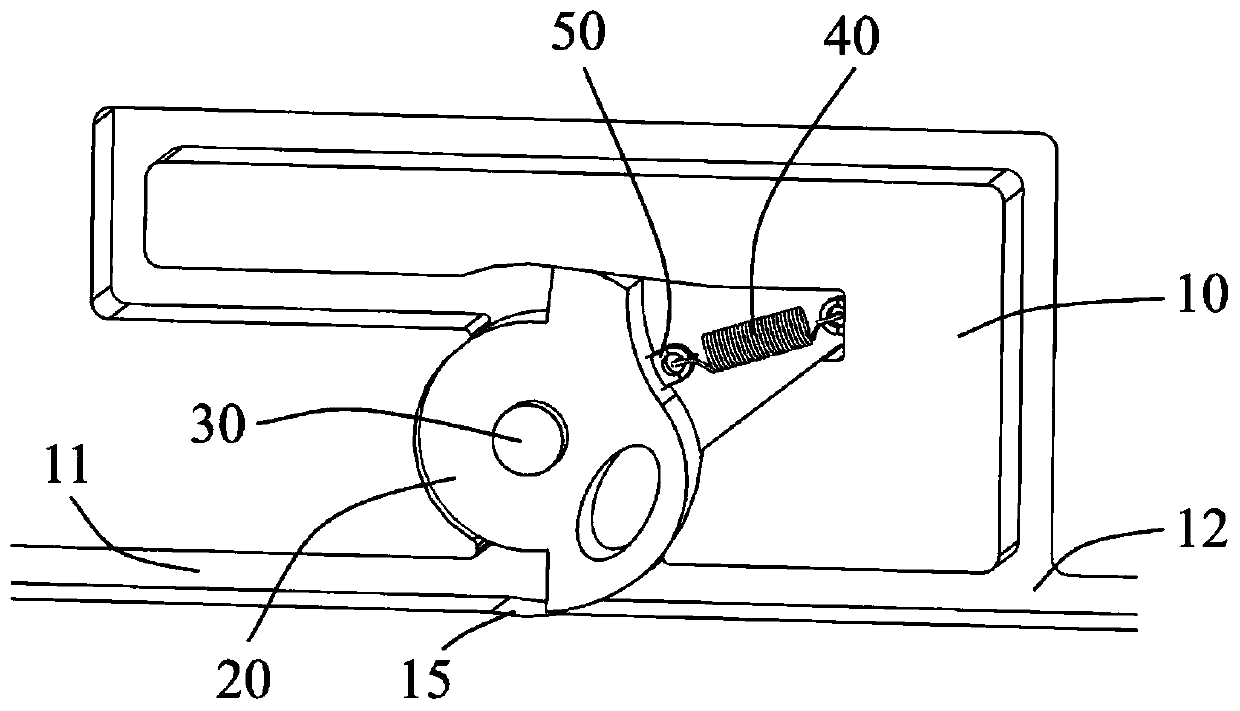

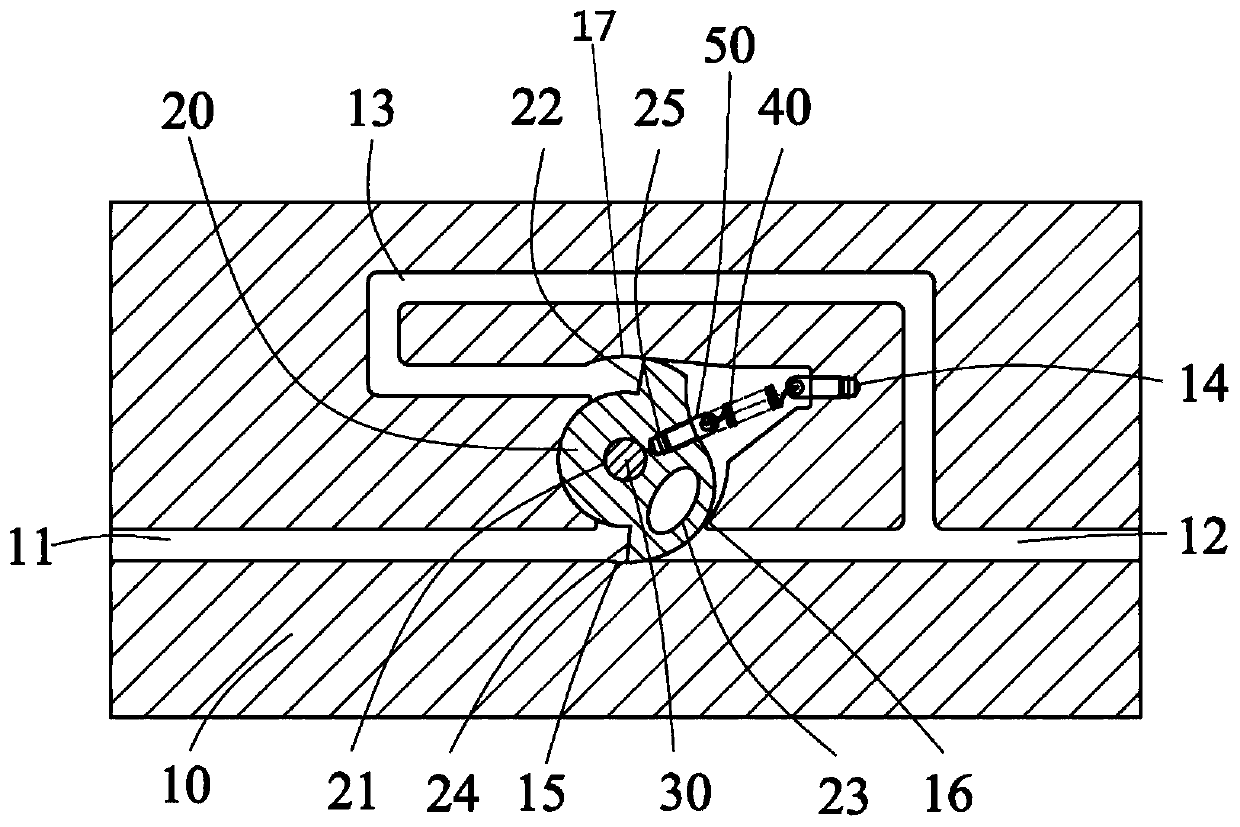

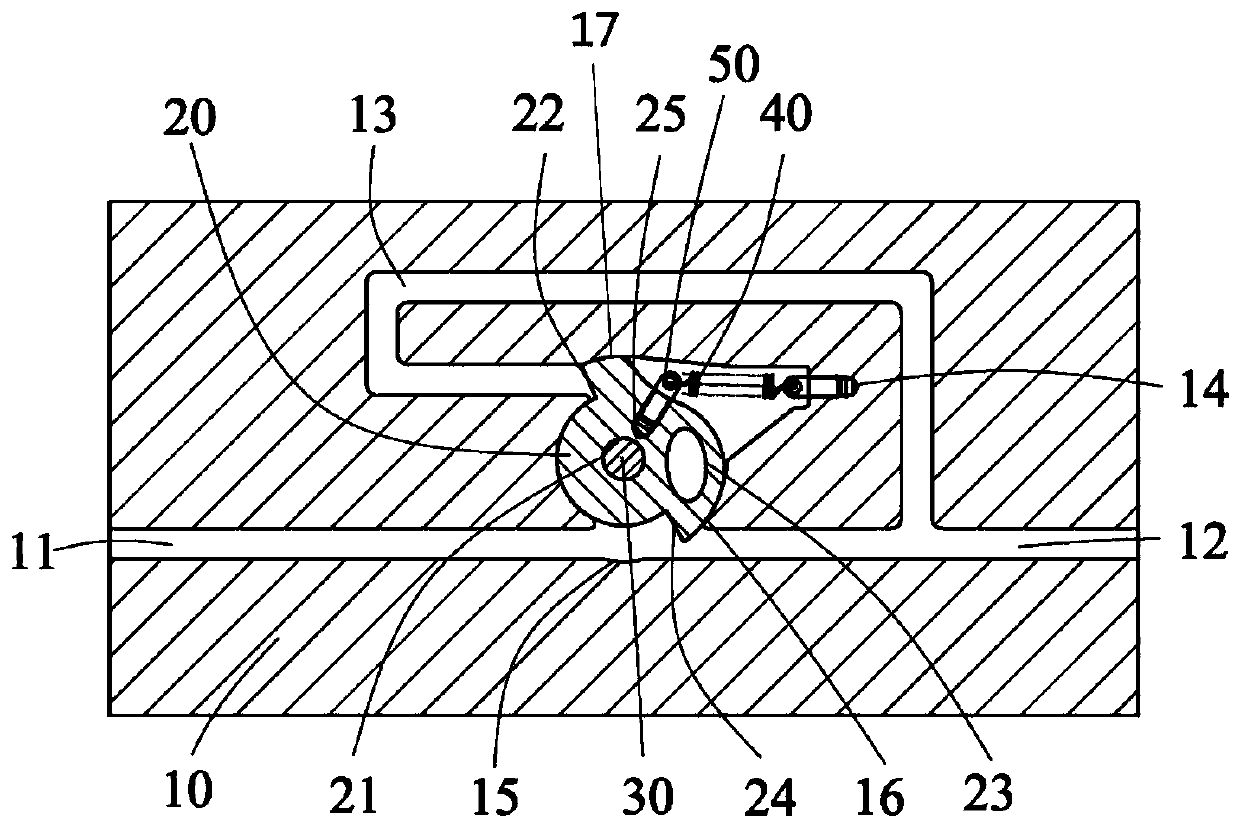

[0026] This embodiment provides a throttle valve. refer to figure 1 , figure 2 , image 3 , Figure 4 , The throttle valve provided in this embodiment includes a valve body 10 , a valve core 20 , a rotating shaft 30 , an elastic member 40 , a first screw 50 , and a second screw 14 .

[0027] The elastic member 40 is a spring, which specifically can be a tension spring, a compression spring, or a torsion spring.

[0028] The valve body 10 is provided with a main pipeline inlet 11 , a main pipeline outlet 12 and a fluid outlet feedback pipeline 13 ; the main pipeline inlet 11 and the main pipeline outlet 12 are located at two ends of a main pipeline.

[0029] One end of the fluid outlet feedback pipeline 13 is located on the branch of the main pipeline outlet 12 , and the other end faces the outlet pressure feedback surface 22 of the valve core 20 . Therefore, the fluid outlet feedback pipe 13 can introduce the outlet fluid (or gas) to the outlet pressure feedback acting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com