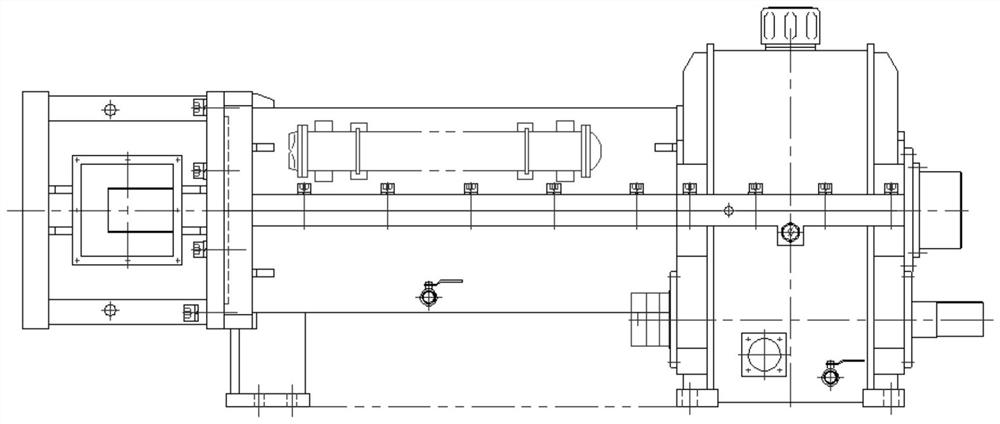

Co-rotating bevel double gearbox with flexible shaft coupling

A technology of couplings and flexible shafts, which is applied in the direction of rigid shaft couplings, elastic couplings, couplings, etc., can solve the problems of small torque and easy damage of wheel bearings, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

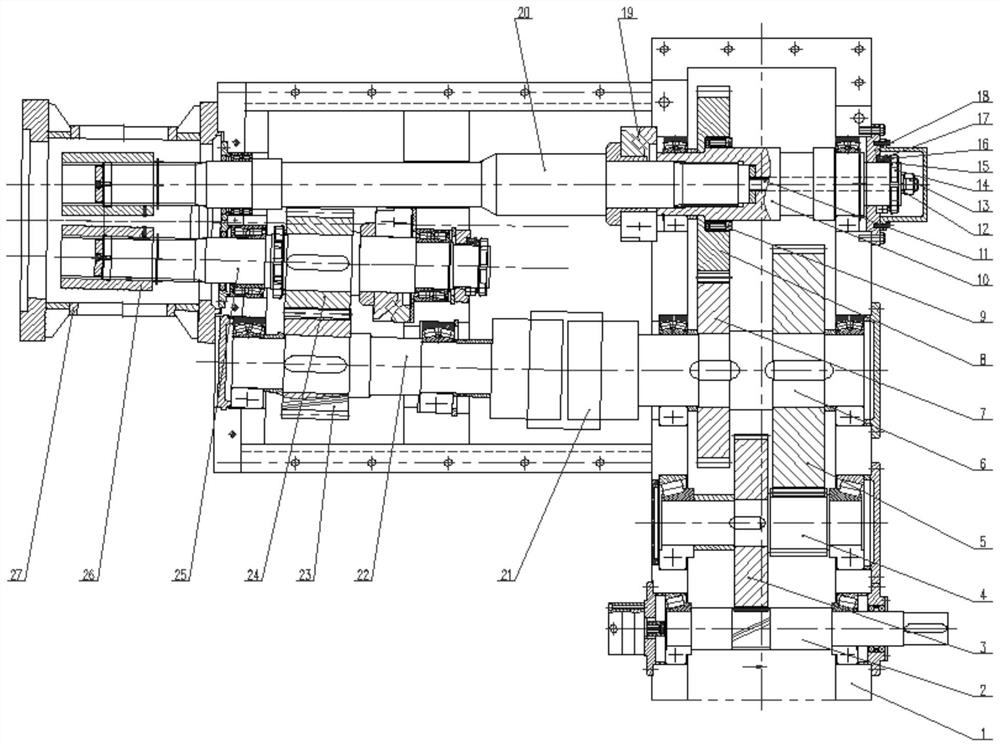

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

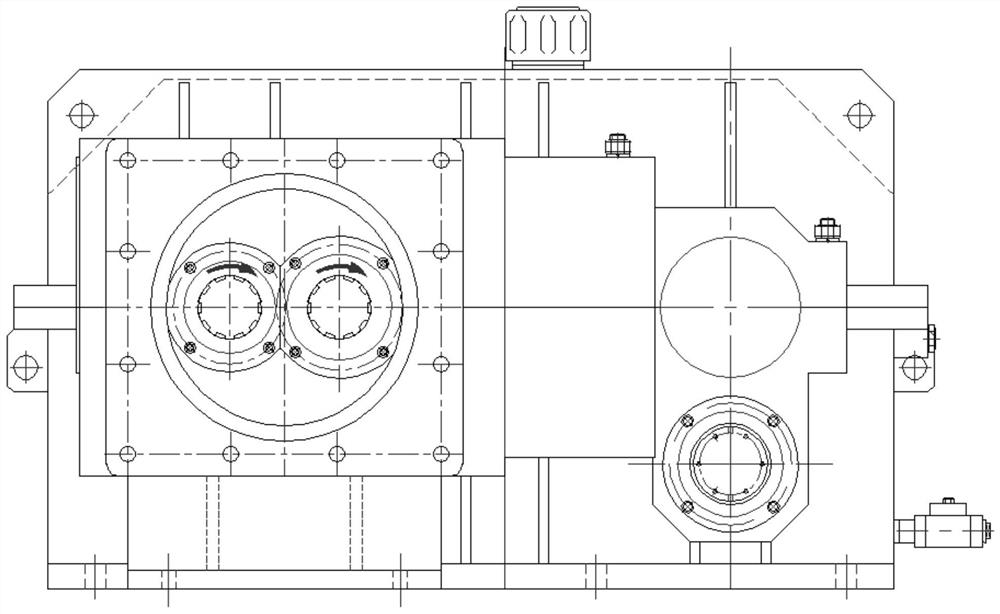

[0017] Depend on figure 2 It can be seen that the co-rotating bevel double gearbox adopting a flexible shaft coupling of the present invention includes a casing 1, an input shaft 2, a pinion 3, a gear shaft 4, a bull gear 5, a transmission shaft 6, a transition wheel 7, Transition wheel 2 8, expansion sleeve 9, transmission shaft 2 10, stud 11, washer 12, nut 13, lock nut 14, washer 15, spacer ring 16, thrust ball bearing 17, ball bearing seat 18, thrust shaft 19 , output long shaft 20, flexible shaft coupling 21, transmission shaft three 22, left-handed distribution gear 23, right-handed distribution gear 24, output short shaft 25, spline sleeve 26, connection plate 27.

[0018] Input shaft 2, gear shaft 4, transmission shaft 1 6, and transmission shaft 2 10 are installed in parallel in the transmission box body of casing 1, and pinion 3 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com