Automatic door derail-preventing rail

An automatic door, derailment prevention technology, applied in door/window accessories, switches with brakes, wing parts, etc., can solve the problems of frame friction or collision, slider detachment, jamming, etc., to speed up startup , the effect of reducing vibration, reducing collision and friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

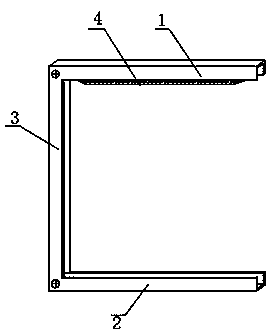

[0017] Such as Figure 1-3 As shown, an automatic door anti-derailment track includes an upper track 1, a lower track 2 and a storage frame 3. The upper track 1, the lower track 2 and the storage frame 3 are fixedly connected by rivets, and the lower end surface of the upper track 1 is riveted with an extended guard Plate 4 increases the limit width of the upper rail 1, and the interior of the storage frame 3 is welded in turn from top to bottom with No. 1 channel steel 5 and No. 2 channel steel 6, and both No. 1 channel steel 5 and No. 2 channel steel 6 run through Three sets of springs 7 are installed; a guide rail 8 is welded at the inner middle position of the lower track 2, and the upper end surface of the guide rail 8 is provided with an ant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com