Drainage pipeline construction component and method

A technology for drainage pipelines and components, which is applied to drainage pipeline construction components and their construction fields, can solve the problems of inability to take into account positioning stability and free positioning, and high stability of positioning degrees of freedom, so as to improve construction reliability, reduce construction damage, and improve reliability. The effect of high degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

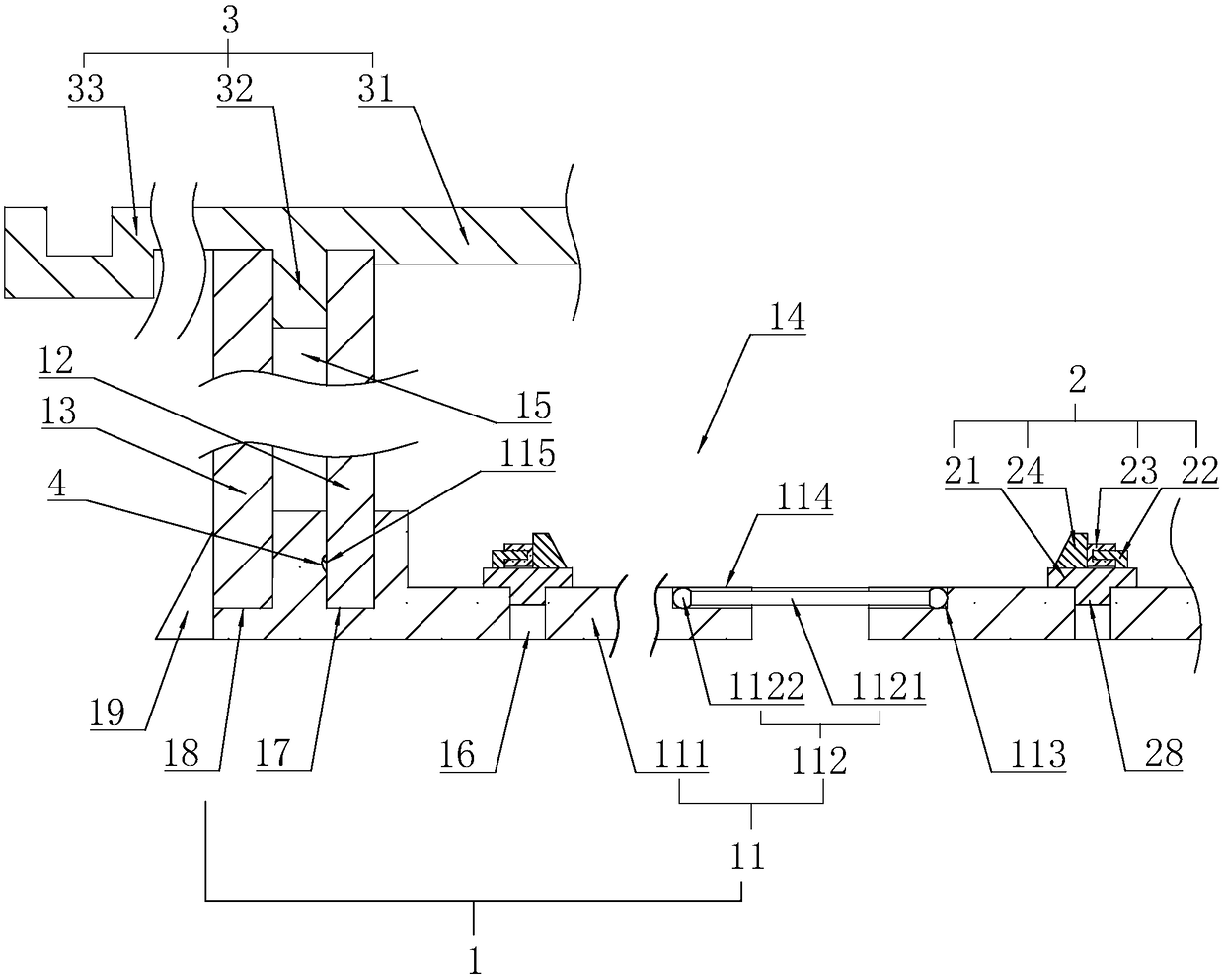

[0045] Example 1: Sewer pipe construction components such as figure 1 As shown, it includes an external frame 1 , a base assembly 2 and a cover assembly 3 .

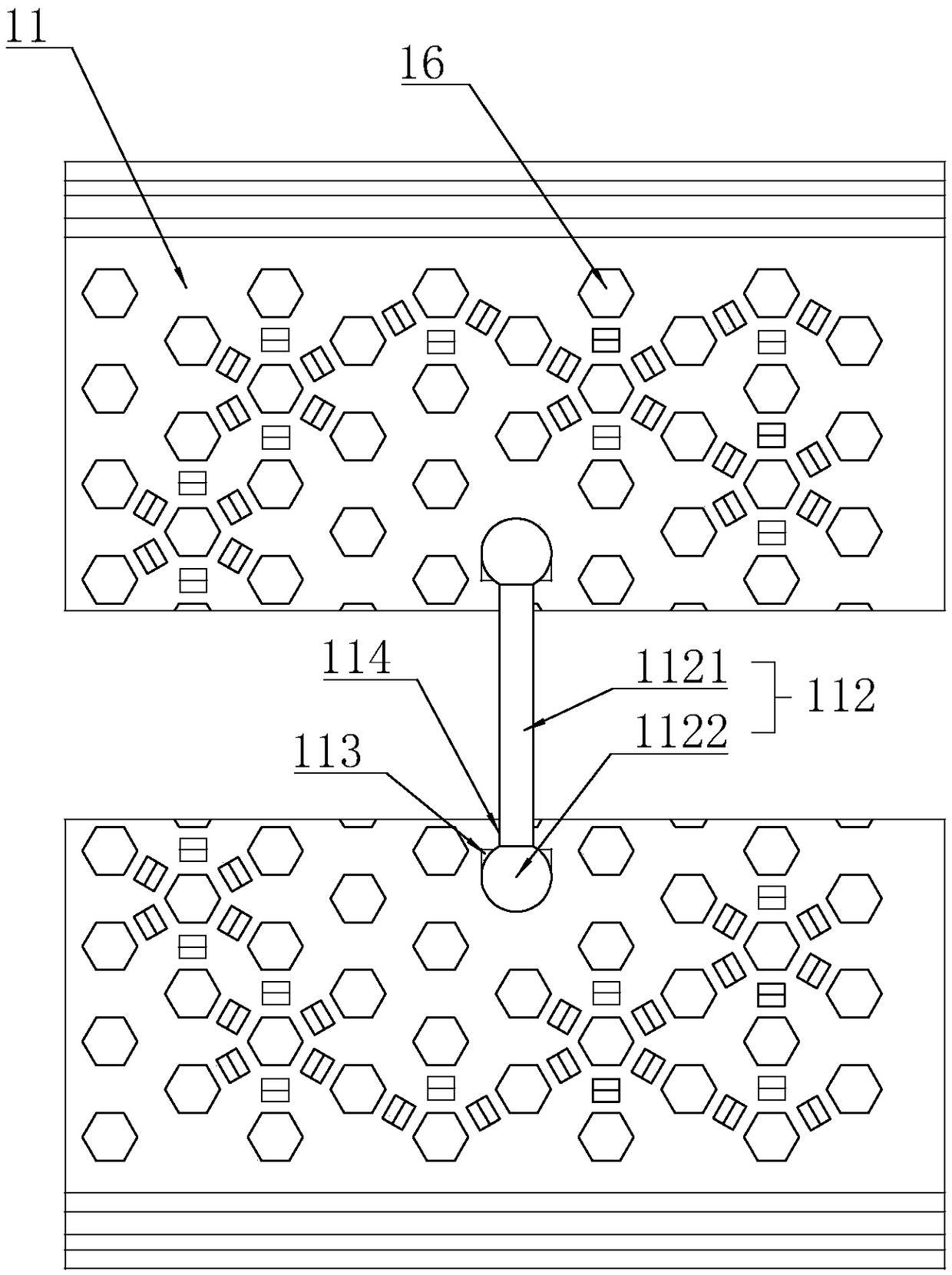

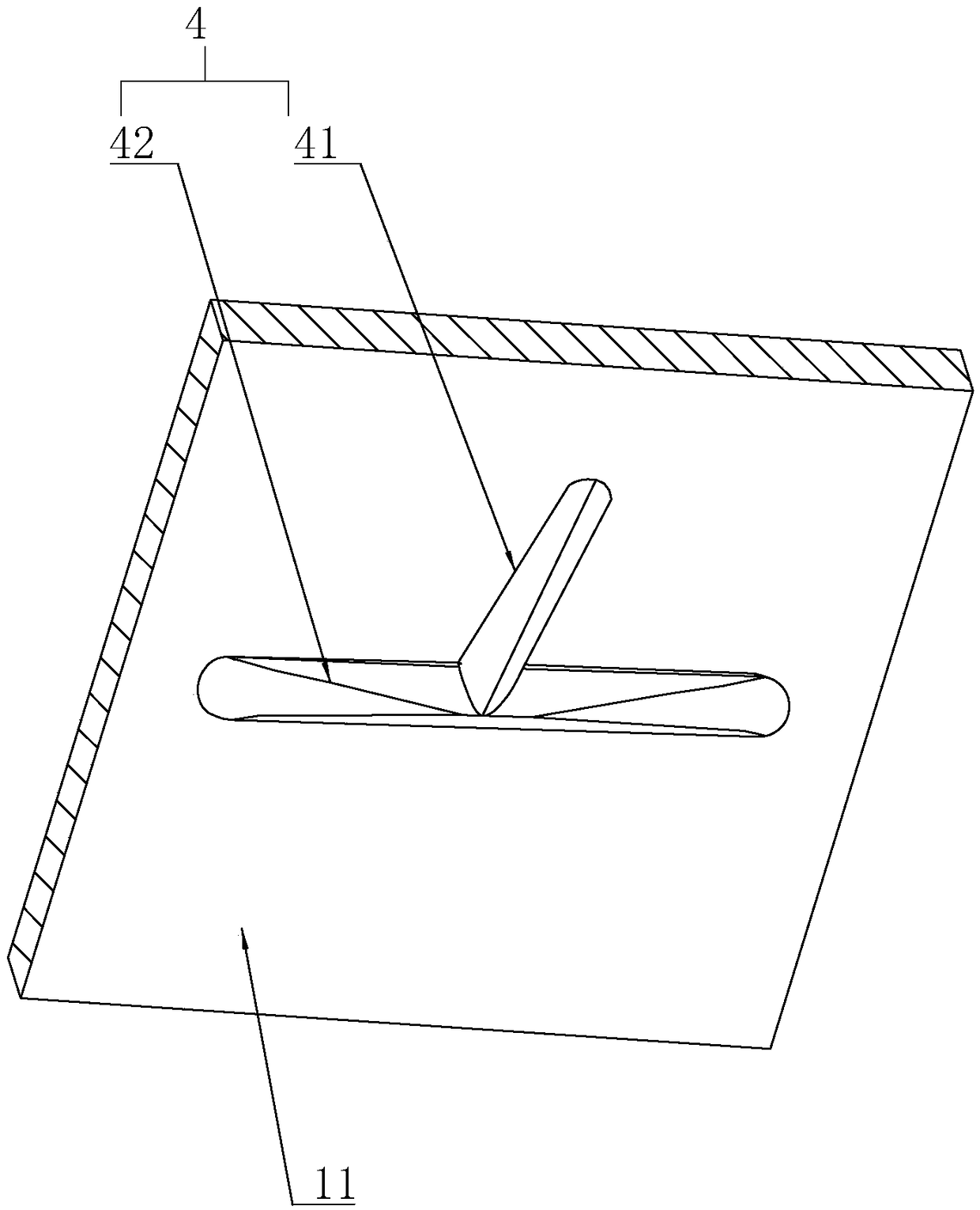

[0046] The external frame 1 includes a base plate 11, two inner plates 12 and two outer plates 13; the two inner plates 12 and the base plate 11 are combined to form a mounting groove 14, and a fixing groove 15 is formed between the inner plate 12 and the outer plate 13. On the base plate 11 A positioning groove 16 is provided through it.

[0047] refer to figure 1 and figure 2 The bottom plate 11 includes two seat plates 111 and a connector 112 connecting the seat plates 111. The connector 112 includes a rod portion 1121 and a spherical end 1122 whose diameter is larger than the rod portion 1121. The seat plate 111 is provided with a socket for the spherical end 1122 to insert. The limiting groove 113 connected to it and the via hole 114 through which the rod portion 1121 passes, the limiting groove 113 runs through...

Embodiment 2

[0052] Embodiment 2, the construction that adopts construction assembly comprises the following steps:

[0053] Step S1 After the excavation of the trench is completed, clean the bottom of the trench according to the designed elevation of the trench bottom, and sprinkle water in a smooth manner;

[0054] Step S2 laying the trench, laying gravel on the bottom of the trench, and vibrating it to keep the surface smooth;

[0055] Step S3 Install the external frame 1, lay the seat plate 111 symmetrically on the surface of the cushion layer and connect it to the bottom plate 11 with the connector 112; connect the outer plate 13 with the outer embedded groove 18 of the bottom plate 11, and keep it vertical all the time, and then Fill concrete between the outer panel 13 and the inner wall of the groove; then abut the inner panel 12 with the embedded groove 17;

[0056] Step S4: Install the bottom assembly 2, install the bottom assembly 2 at the corresponding position through the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com