Assembled steel-structure tower crane foundation and construction method

A tower crane foundation and steel structure technology, applied in the direction of foundation structure engineering, construction, etc., can solve the problems of poor overall stability and overturning resistance of the upper steel beam, troublesome splicing, and reduced rigidity, and achieve anti-overturning stability and component self-resistance Good torsion, high construction efficiency, and the effect of eliminating deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

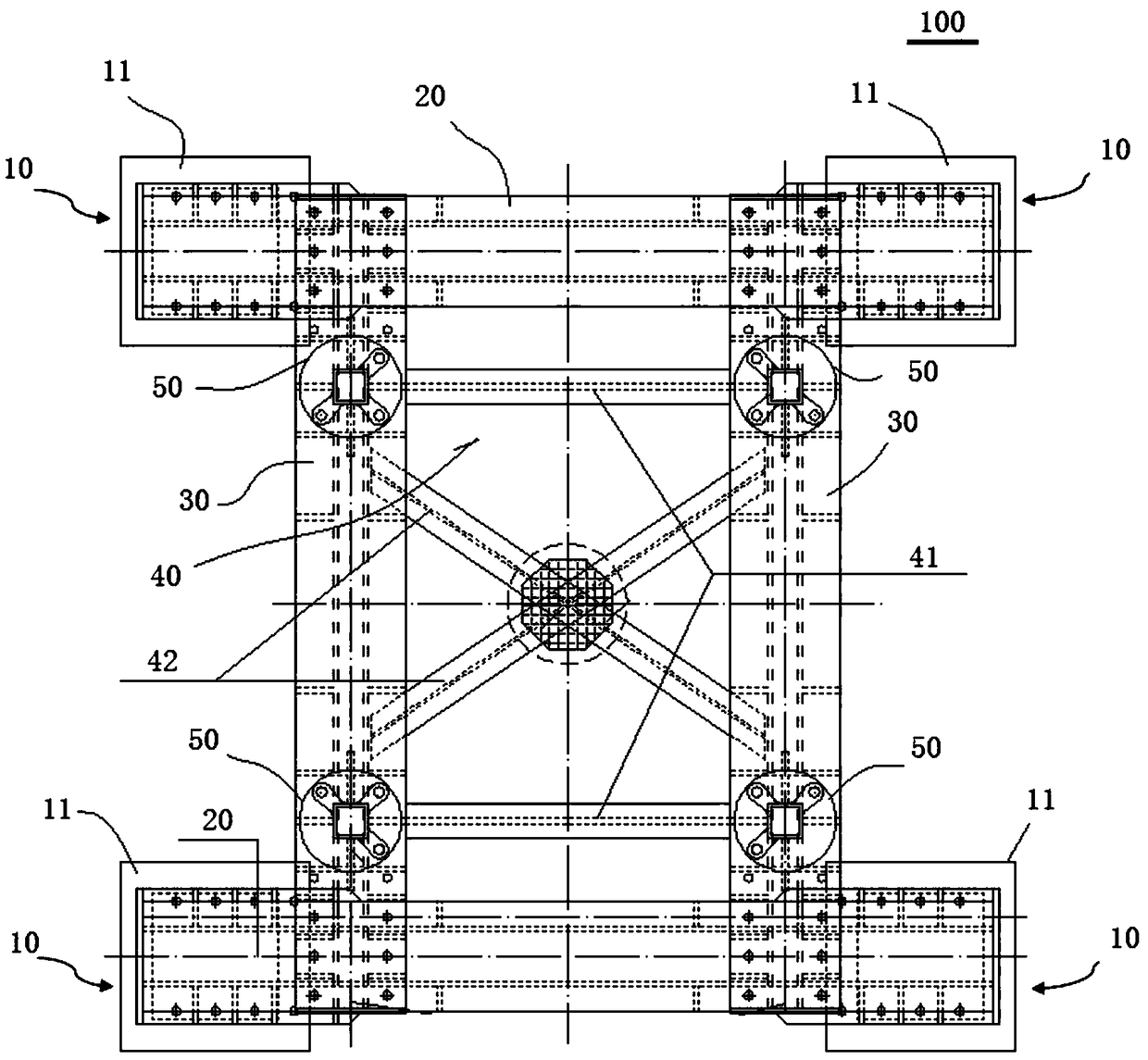

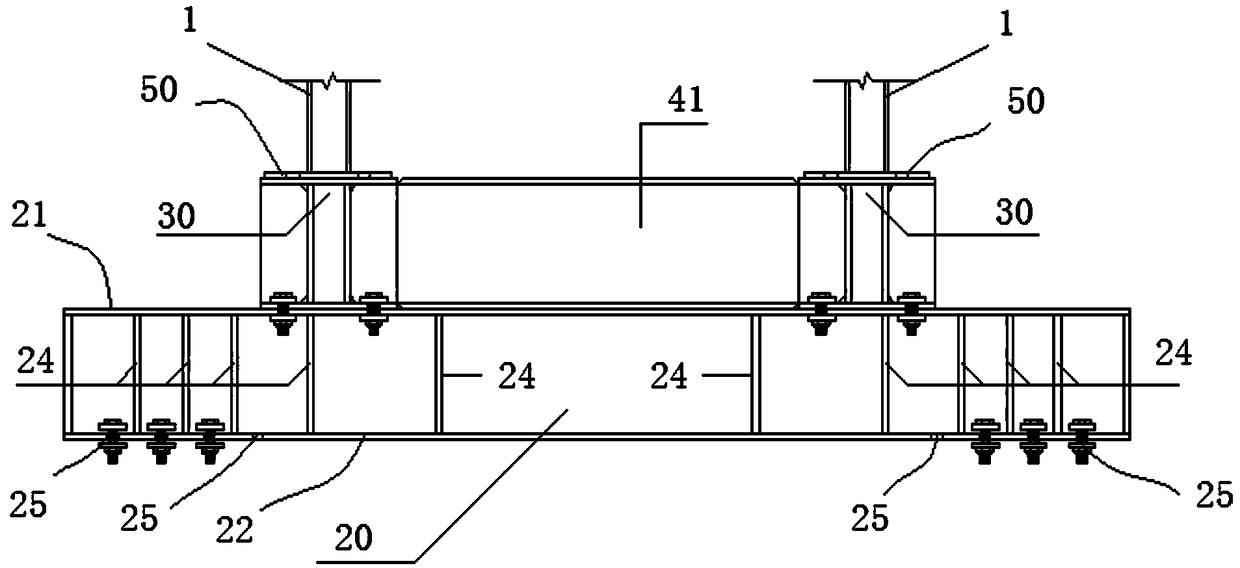

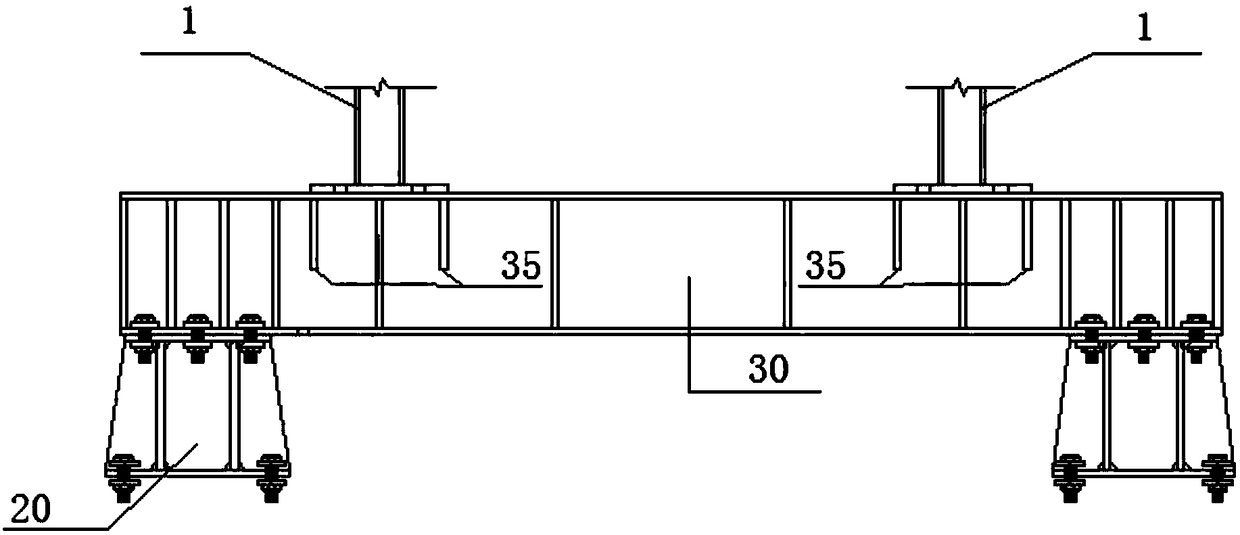

[0060] Such as Figure 1 to Figure 12 As shown, a kind of prefabricated steel structure tower crane foundation 100 provided in this embodiment is installed on four steel lattice columns 2 (see Figure 13-Figure 17 ), each steel lattice column 2 is fixed on the corresponding bored pile (not shown in the figure). In this embodiment, four steel lattice columns 2 are arranged in a square. Such as figure 1 shown, see also Figure 2-Figure 3 , the fabricated steel structure tower crane foundation 100 includes: four column caps 10, two steel main beams 20, two steel main beams 20, two steel secondary beams 30, four steel tie beams 40 and four circular Steel backing plate 50. The four column caps 10 are installed on the four steel lattice columns 2 correspondingly. see Figure 13 , see also Figure 14-Figure 17 , each column cap 10 includes a cover plate 11 and a plurality of stiffening plates 12 vertically fixed to the bottom of the cover plate 11 . Such as figure 1 shown, s...

Embodiment 2

[0084] see Figure 1-Figure 17 , the present invention also provides a construction method for the fabricated steel structure tower crane foundation 100 as described above, which is performed according to the following steps:

[0085] Step 100, construction of bored piles;

[0086] After the construction preparation is completed, the casing is buried. Then carry out pile driver positioning, adjustment and centering. Then drill into the hole, and clean the hole once after the hole is completed. After the hole clearing is completed, the sediment is initially measured, the steel cage is hoisted, and the downcomer is carried out. Secondary emptying is then carried out, and concrete pouring is carried out after completion.

[0087] In step 200, the steel lattice column 2 is constructed.

[0088] During the construction of the steel lattice column 2, the prepared steel lattice column 2 is welded on a short steel cage in advance, which should meet the lifting requirements of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com