A kind of preparation method of grinding wheel of tread cleaner

A cleaner and formula technology, applied in vehicle cleaning, metal processing equipment, vehicle maintenance, etc., can solve the problems of reducing production and maintenance costs, achieve the effect of reducing energy consumption of presses and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

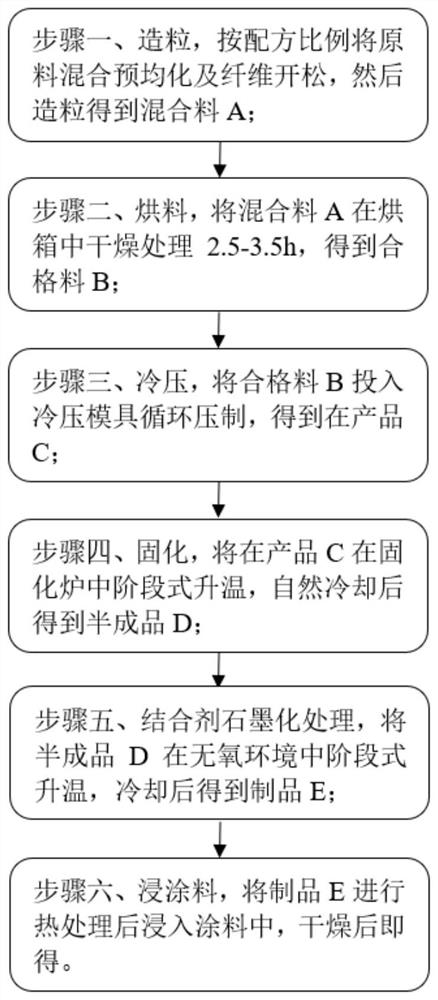

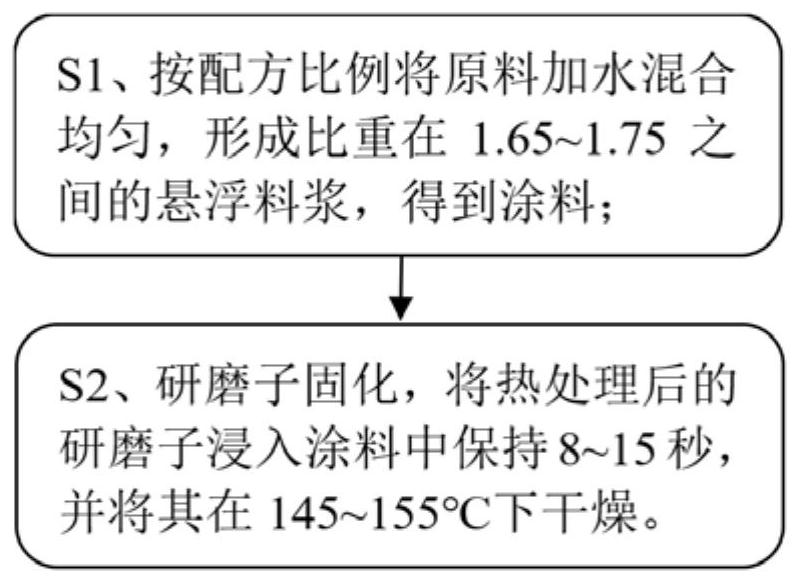

[0041] combine figure 1 and figure 2 , a kind of preparation method of tread sweeper grinder of the present embodiment, comprises the following steps:

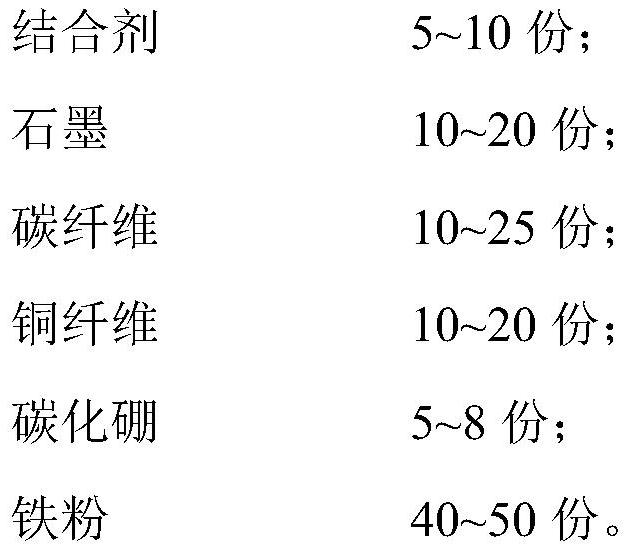

[0042] Step 1, granulation, put the binder, graphite, carbon fiber, copper fiber, boron carbide and iron powder into the mixer in sequence according to the formula ratio for pre-homogenization and fiber opening. The pre-homogenization time is 580s, and then add The organic solvent is used for granulation, and the granulation time is 120s to obtain the mixture A;

[0043] Step 2, drying the material, putting the mixture A into an oven for drying treatment, the drying time is 2.5 hours, and obtaining the qualified material B, and the qualified material B is a mixture with a volatile content of less than 1%;

[0044] Step 3, cold pressing, put the qualified material B into the cold pressing mold for cyclic pressing, the specific process parameters are as follows: the product surface pressure is 50MPa for 30s, 30MPa for 60s, 50...

Embodiment 2

[0063] A kind of preparation method of tread cleaner grinder of the present embodiment, its steps are basically the same as embodiment 1, the difference is:

[0064] Step 1, granulation, put the binder, graphite, carbon fiber, copper fiber, boron carbide and iron powder into the mixer in turn according to the formula ratio for pre-homogenization and fiber opening. The pre-homogenization time is 600s, and then add The organic solvent is used for granulation, and the granulation time is 120s to obtain the mixture A;

[0065] Step 2, drying the material, putting the mixture A into an oven for drying treatment, the drying time is 3 hours, and obtaining the qualified material B, and the qualified material B is a mixture with a volatile content of less than 1%;

[0066] Step 3, cold pressing, put the qualified material B into the cold pressing mold and press it circularly. The specific process parameters are as follows: the product surface pressure is 20MPa for 30s, 40MPa for 60s, 5...

Embodiment 3

[0079] A kind of preparation method of tread cleaner grinder of the present embodiment, its steps are basically the same as embodiment 1, the difference is:

[0080] Step 1, granulation, put the binder, graphite, carbon fiber, copper fiber, boron carbide and iron powder into the mixer in turn according to the formula ratio for pre-homogenization and fiber opening. The pre-homogenization time is 620s, and then add The organic solvent is used for granulation, and the granulation time is 110s to obtain the mixture A;

[0081] Step 2, drying the material, putting the mixture A into an oven for drying treatment, the drying time is 2.8h, and obtaining the qualified material B, and the qualified material B is a mixture with a volatile content of less than 1%;

[0082] Step 3, cold pressing, put the qualified material B into the cold pressing mold for cyclic pressing, the specific process parameters are as follows: the product surface pressure is 11MPa for 30s, 27MPa for 60s, 50MPa fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com