Preparation method and application of biodegradable rare earth fluorescent film

A biodegradable, rare-earth fluorescence technology, applied in chemical instruments and methods, luminescent materials, compounds containing Group 3/13 elements of the periodic table, etc., can solve the problems of low light energy conversion efficiency, white pollution, non-degradability, etc. , to achieve the effect of long red light luminescence performance, good agricultural value and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

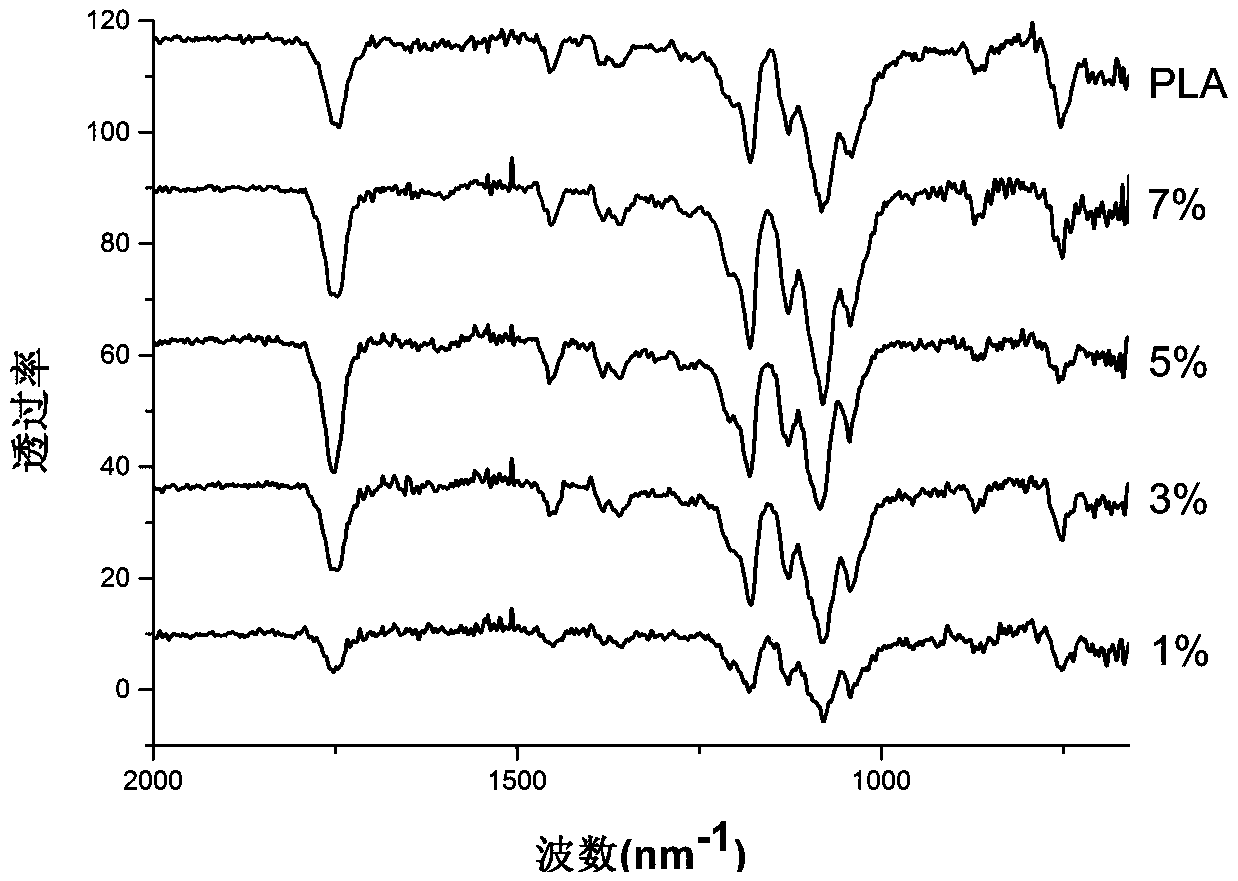

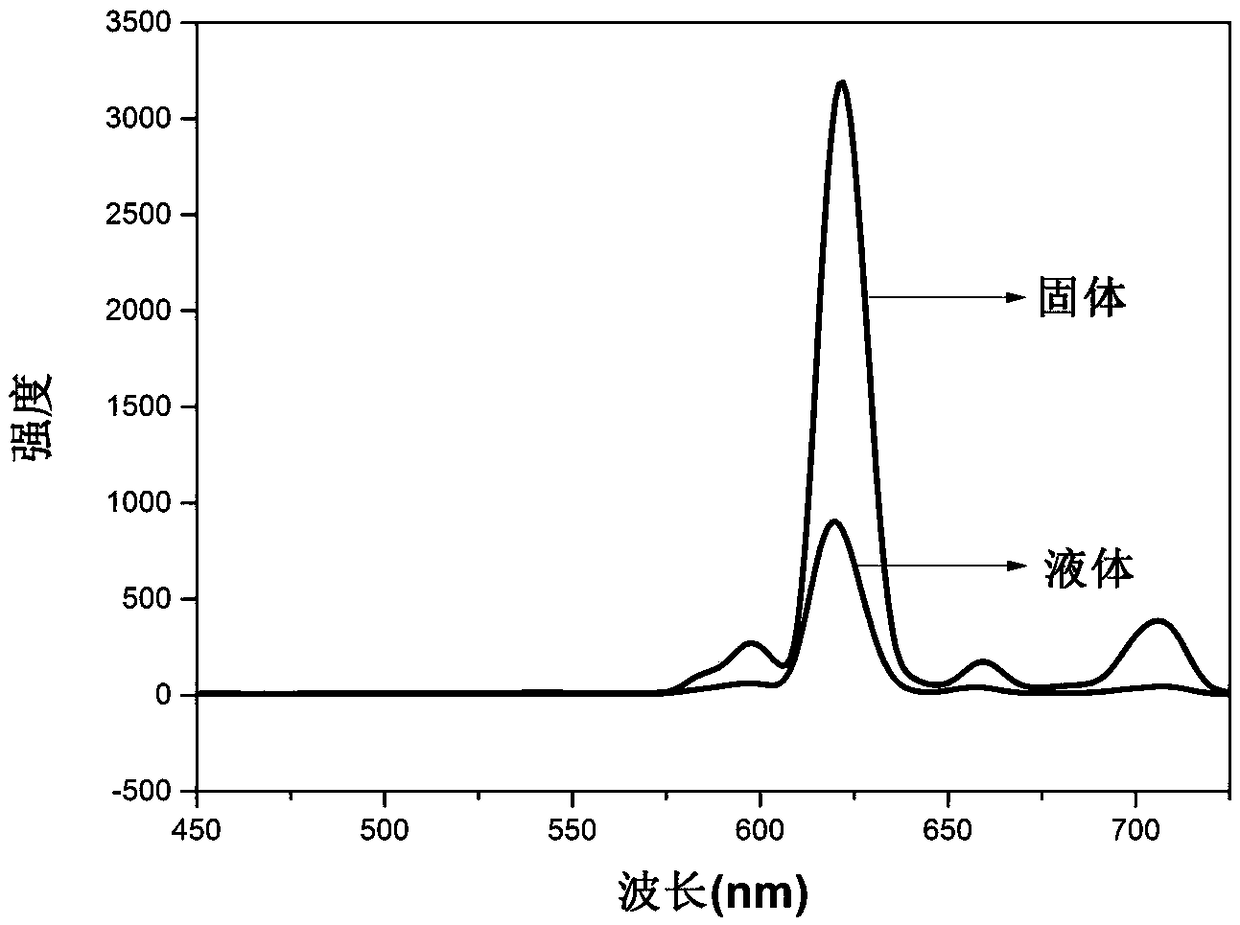

[0041] The invention relates to a preparation method of a biodegradable rare earth fluorescent film, in which a trinuclear rare earth europium complex luminescent material Eu is doped in a PLA matrix. 3 (TTA) 9 -TPMB, obtain the biodegradable rare earth fluorescent film with PLA as matrix; Wherein, PLA and Eu 3 (TTA) 9 -The mass ratio of TPMB is 100:(1~10).

[0042] Wherein, the trinuclear rare earth europium complex luminescent material has a molecular formula of Eu 3 (TTA) 9 -TPMB, prepared by mixing 0.2610g EuTTA 3 2H 2 O was fully dissolved in 30ml of tetrahydrofuran (THF), and 0.1048g of ligand TPMB was added, and the temperature was raised to 75°C with stirring, and after constant temperature reaction for 3 hours, the excess THF was rotary evaporated to obtain the product Eu 3 (TTA) 9 -TPMB. The trinuclear rare earth europium complex luminescent material can also be applied to the fields of biological imaging, sensing, anti-counterfeiting, agricultural film, traf...

Embodiment 1

[0044] The biodegradable rare earth fluorescent film with PLA as the substrate is prepared by the following method:

[0045] 1) Accurately weigh 0.0005g of Eu 3 (TTA) 9 -Add TPMB to the centrifuge tube, then measure 1mL of THF and add it to the beaker, shake until Eu 3 (TTA) 9 - TPMB is completely dissolved.

[0046] 2) Weigh 1g of PLA particles into the beaker, then measure 100mL of chloroform into the beaker, stir until the PLA is completely dissolved, and obtain a 10g / L PLA solution.

[0047] 3) Measure 5ml of PLA solution and add it dropwise to the 3 (TTA) 9 -Put the TPMB solution into a centrifuge tube and put it into an ultrasonic cleaner to make it fully miscible.

[0048] 4) Drop the above-mentioned miscible solution onto the glass slide with a dropper, put it into an evaporating dish, cover the surface with a fresh-keeping film, and allow the solution to slowly evaporate for 12 hours. After the solvent evaporates completely, the complex Eu 3 (TTA) 9 - A biode...

Embodiment 2

[0050] 1) Accurately weigh 0.0015g of Eu 3 (TTA) 9 -Add TPMB to the centrifuge tube, then measure 1mL of THF and add it to the beaker, shake until Eu 3 (TTA) 9 - TPMB is completely dissolved.

[0051] 2) Weigh 1g of PLA particles into the beaker, then measure 100mL of chloroform into the beaker, stir until the PLA is completely dissolved, and obtain a 10g / L PLA solution.

[0052] 3) Measure 5ml of PLA solution and add it dropwise to the 3 (TTA) 9 -Put the TPMB solution into a centrifuge tube and put it into an ultrasonic cleaner to make it fully miscible.

[0053] 4) Drop the above-mentioned miscible solution onto the glass slide with a dropper, put it into an evaporating dish, cover the surface with a fresh-keeping film, and allow the solution to slowly evaporate for 12 hours. After the solvent evaporates completely, the complex Eu 3 (TTA) 9 - A biodegradable rare-earth fluorescent film with a TPMB mass of 3% and a PLA concentration of 10g / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com