Method for refining biphenyl by hydrogenating industry fluorene oxide in normal pressure hydrogen

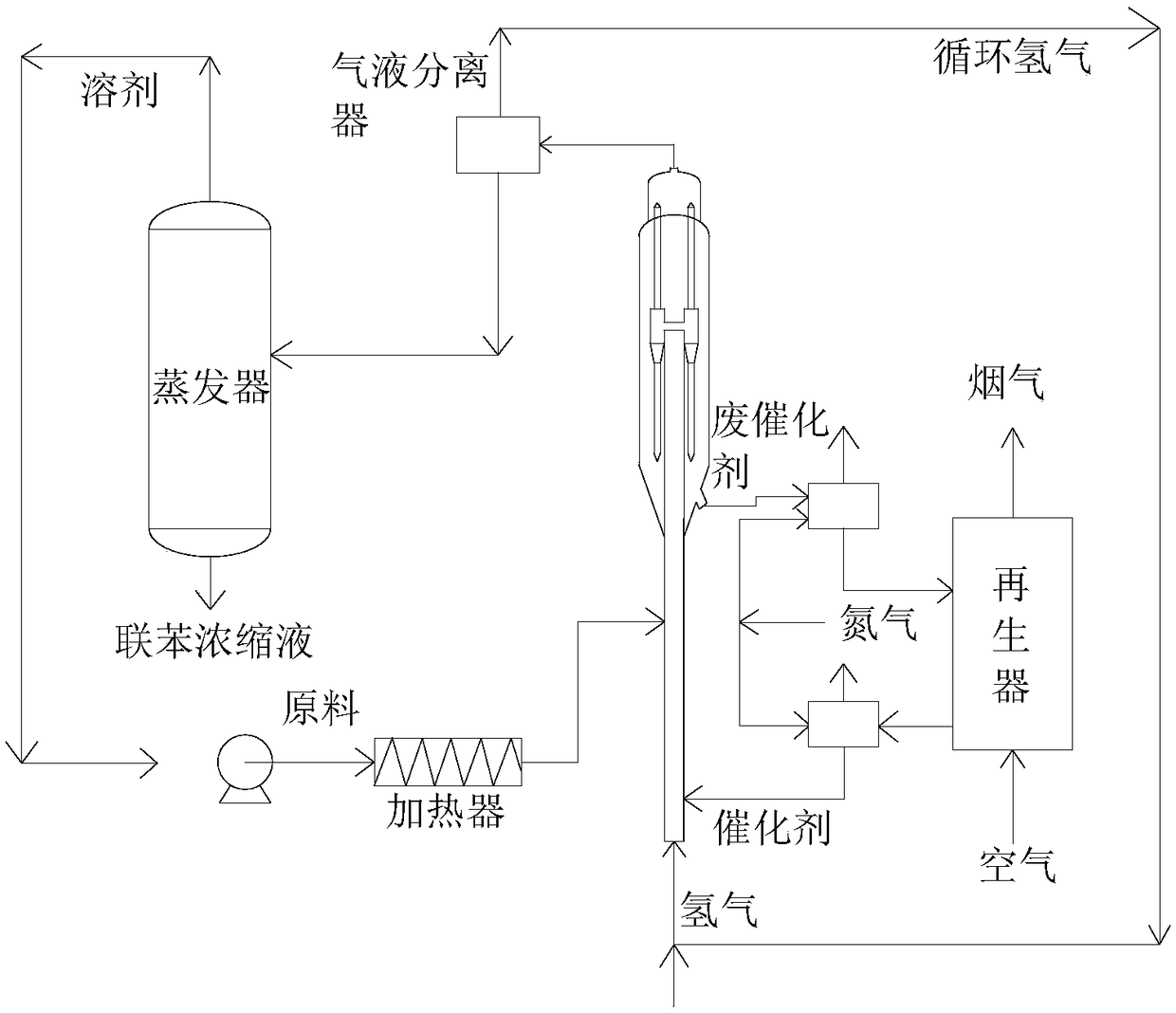

An industrial oxygen fluorene and hydrorefining technology, applied in chemical instruments and methods, hydrocarbons, hydrocarbons, etc., can solve the problems of increasing equipment costs and product separation difficulties, achieving simple process, reducing equipment costs and operation. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: MoO 3 Synthesis method: Mix a certain amount of ammonium molybdate aqueous solution with melamine aqueous solution, the solution becomes turbid, and then filter, and the obtained filter cake is heated up to 500°C at 2°C / min in the air, kept at constant temperature for 4 hours, cooled naturally, and set aside. Mo 2 N synthesis method: a certain amount of MoO 3 in N 2 / H 2 Nitriding is carried out under the atmosphere, the specific ammoniation process: 1 ℃ / min from room temperature to 800 ℃, constant temperature for 6 hours, natural cooling to room temperature, passivation treatment. Pt / MoO 3 , Pt / Mo 2 N. Co / MoO 3 、Co / Mo 2 N. Ni / MoO 3 and Ni / Mo 2 Synthesis method of N catalyst: the obtained catalyst is dried, calcined, and then reduced for later use by using a common impregnation method.

Embodiment 2

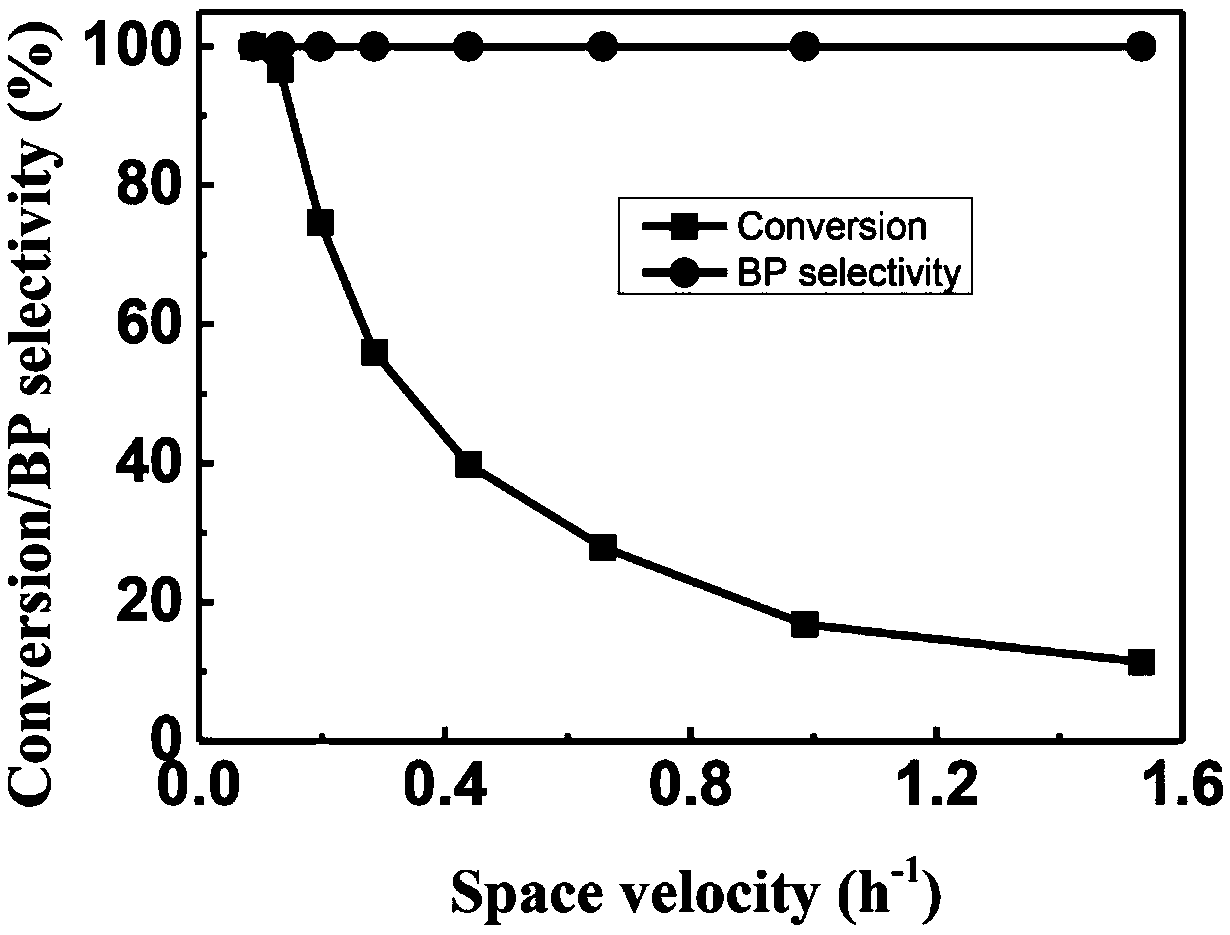

[0023] Example two: 3Co / MoO prepared in Example 1 3 It is a fixed bed hydrogenation catalyst. Investigate the effect of temperature on the reaction results. Biphenyl (BP), see reaction result in table 1 below.

[0024]

[0025] It can be known from Table 1 that the increase of temperature is beneficial to the conversion of DBF, and the selectivity of BP remains 100% regardless of temperature.

Embodiment 3

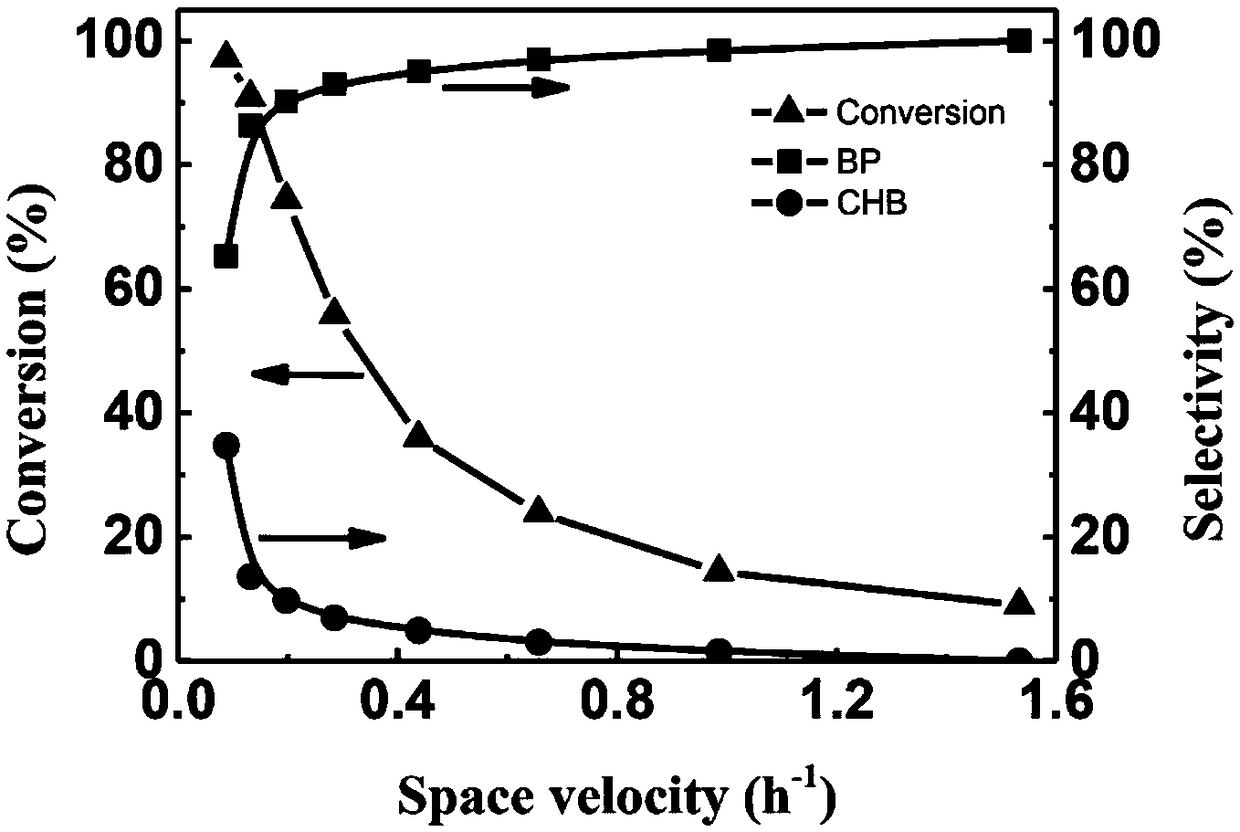

[0026] Embodiment three: 3Ni / MoO prepared with embodiment 1 3 It is a fixed bed hydrogenation catalyst. Investigate the effect of temperature on the reaction results. Biphenyl (BP), cyclohexylbenzene (CHB) see the reaction results in Table 2 below.

[0027]

[0028] It is known from Table 2 that the increase of temperature is beneficial to the conversion of DBF, and the selectivity of BP increases with the increase of temperature. Therefore, high temperature is beneficial to increase the yield of BP.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com