Dedicated carbon-based fertilizer for cotton fields and preparation method thereof

A carbon-based fertilizer, cotton field technology, applied in the application, nitrogen fertilizer, potash fertilizer and other directions, can solve the problem of not being suitable for cotton planting, etc., and achieve the effect of improving the utilization rate of chemical fertilizers, enriching nutrients, and increasing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

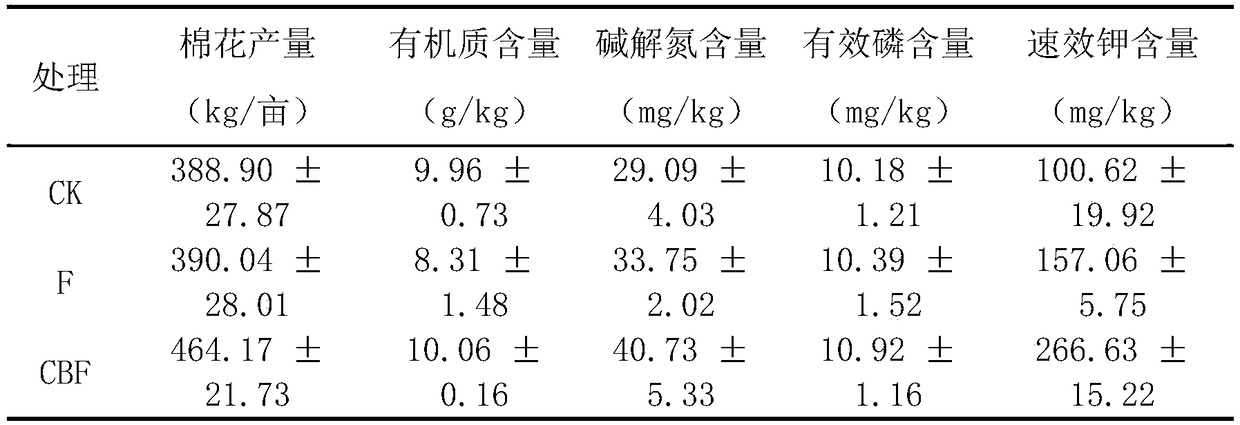

Examples

Embodiment 1

[0029] The biochar-based fertilizer in this embodiment is a special carbon-based fertilizer for cotton fields.

[0030] Crush the gypsum, bentonite and cotton straw biochar, pass the gypsum and bentonite through a 100-mesh sieve, and pass the cotton straw biochar through a 60-mesh sieve.

[0031] The amount of biochar-based fertilizer for cotton dedicated to 100 kg is as follows: mix 16.2 kg of diammonium phosphate, 4.7 kg of urea, 6 kg of potassium sulfate (K2O-50), 30 kg of cotton straw biochar, 12 kg of gypsum and 12 kg of bentonite Come together and stir well to obtain a fertilizer mixture. The temperature of the fertilizer mixture is heated to 60° C., and the water content of the fertilizer mixture is 4 to 10%.

[0032] The fertilizer mixture is firstly granulated with a drum granulator, and then shaped and granulated with a disc granulator to obtain fertilizer granules. In order to match the conveying capacity of the conveyor belt with the output of the drum granulator...

Embodiment 2

[0035] The biochar-based fertilizer in this embodiment is a special carbon-based fertilizer for cotton fields.

[0036] Crush the gypsum, bentonite and cotton straw biochar, pass the gypsum and bentonite through a 100-mesh sieve, and pass the cotton straw biochar through a 60-mesh sieve.

[0037] The addition amount of biochar-based fertilizer for 100 kg of cotton is as follows: mix 16.2 kg of diammonium phosphate, 4.7 kg of urea, 6 kg of potassium sulfate (K2O-50), 35 kg of cotton straw biochar, 9 kg of gypsum and 9 kg of bentonite Come together and stir well to obtain a fertilizer mixture. Heating makes the temperature of the fertilizer mixture at 65°C, and the water content of the fertilizer mixture is 4-10%.

[0038] The fertilizer mixture is firstly granulated with a drum granulator, and then shaped and granulated with a disc granulator to obtain fertilizer granules. In order to match the conveying capacity of the conveyor belt with the output of the drum granulator, th...

Embodiment 3

[0041] The biochar-based fertilizer in this embodiment is a special carbon-based fertilizer for cotton fields.

[0042] Crush the gypsum, bentonite and cotton straw biochar, pass the gypsum and bentonite through a 100-mesh sieve, and pass the cotton straw biochar through a 60-mesh sieve.

[0043] The amount of biochar-based fertilizer for cotton dedicated to 100 kg is as follows: mix 16.2 kg of diammonium phosphate, 4.7 kg of urea, 6 kg of potassium sulfate (K2O-50), 40 kg of cotton straw biochar, 7 kg of gypsum and 7 kg of bentonite Come together and stir well to obtain a fertilizer mixture. Heating makes the temperature of the fertilizer mixture at 70°C, and the water content of the fertilizer mixture is 4-10%.

[0044] The fertilizer mixture is firstly granulated with a drum granulator, and then shaped and granulated with a disc granulator to obtain fertilizer granules. In order to match the conveying capacity of the conveyor belt with the output of the drum granulator, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com