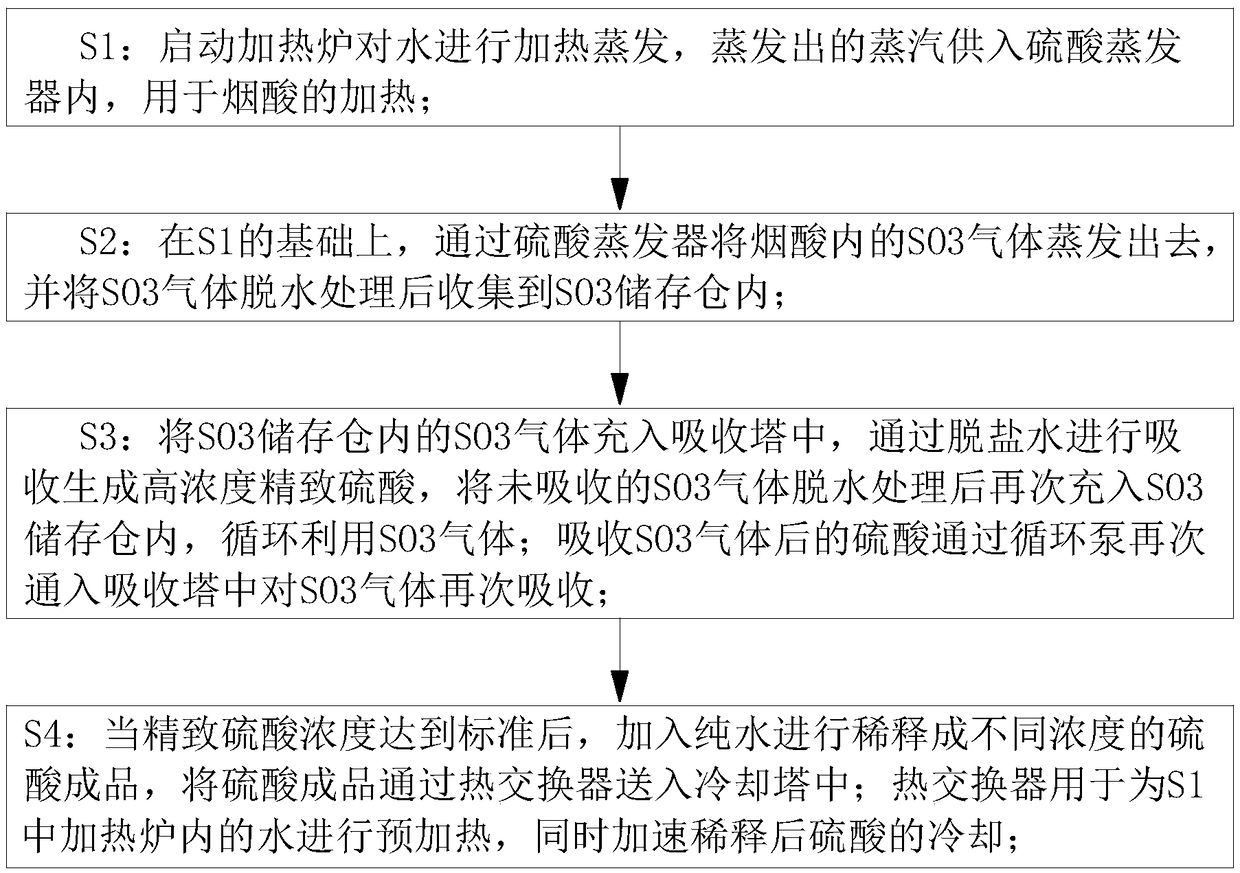

Refined acid production process

A production process and process technology, applied in the field of refined acid production process, can solve the problems of poor fluidity of niacin, uneven evaporation, high cost of U-shaped pipelines, etc., and achieve the effect of increasing the evaporation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

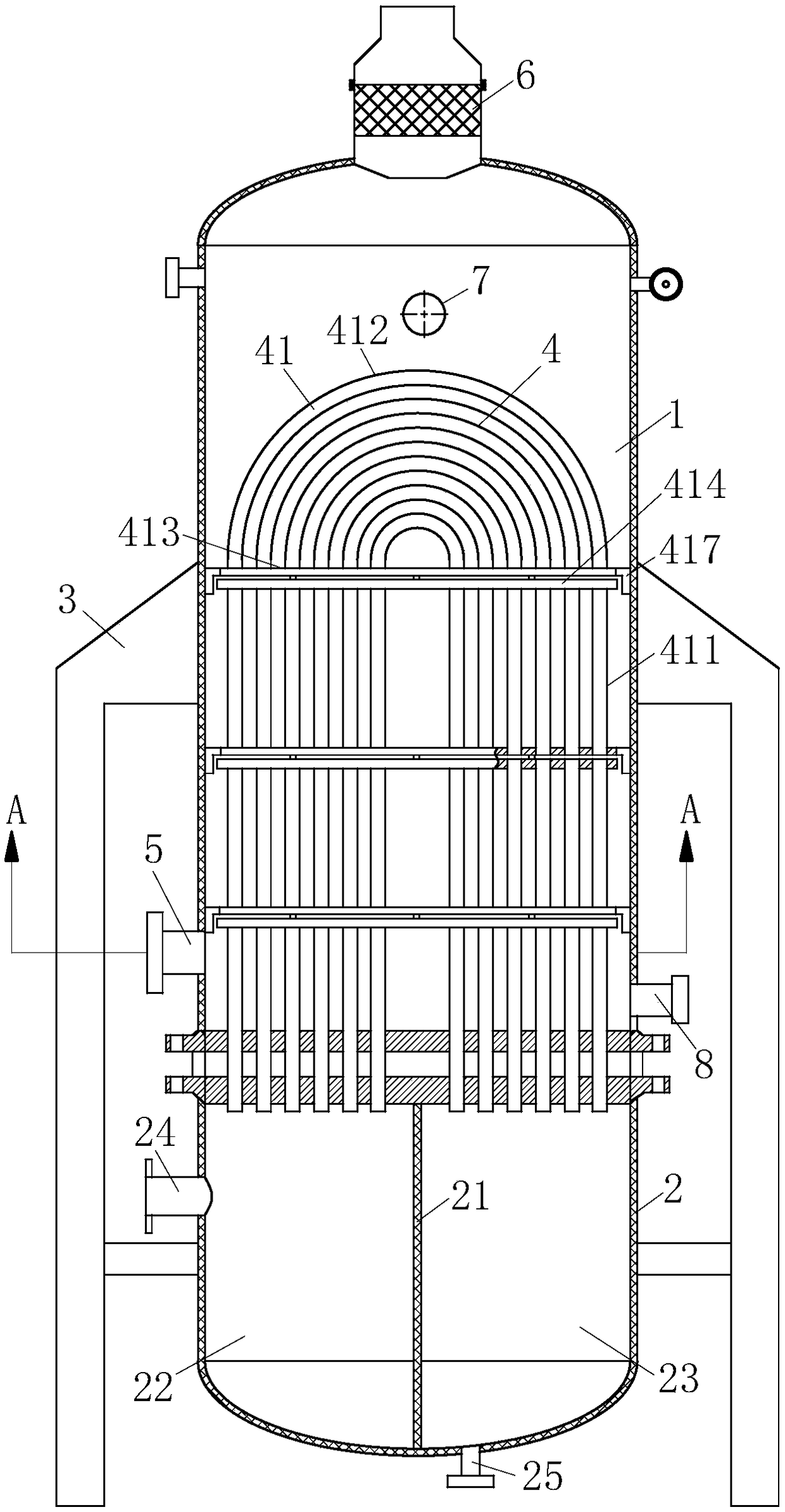

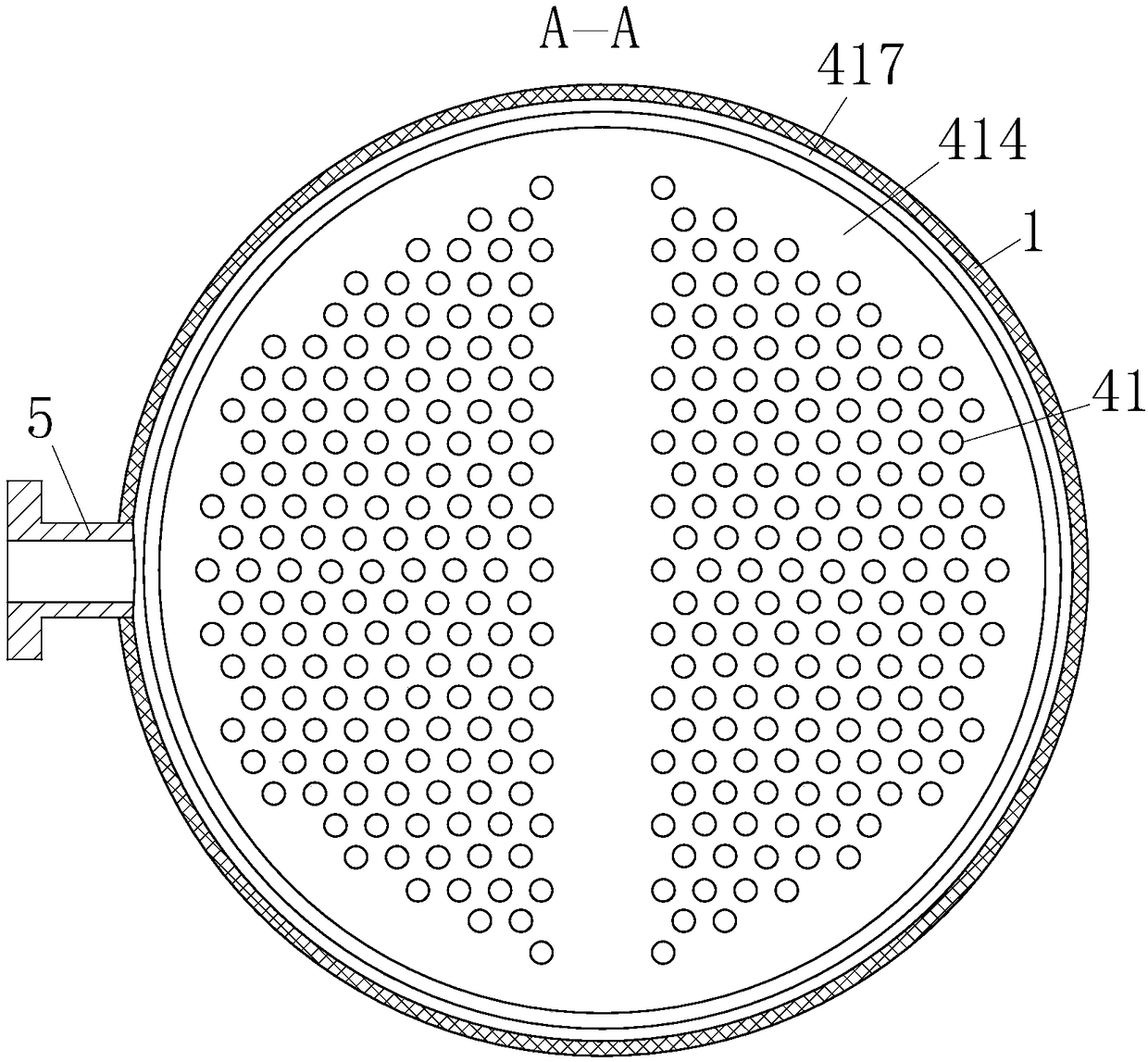

[0038] As an embodiment of the present invention, the fixing part 417 is an annular deflector 418; the annular deflector 418 is sleeved on the side wall of the No. 1 turntable, and the annular deflector 418 is installed on the niacin tank 1, the annular guide plate 418 is used to guide the flow direction of the steam downward. The steam will first blow down the niacin, thereby stirring the niacin below, and then the steam will float up to stir the niacin above, thus increasing the range of steam stirring and further improving the uniformity of niacin being evaporated.

[0039] As an embodiment of the present invention, the sides of the No. 1 disc 413 and the No. 2 disc 414 that are close to each other have a wave-shaped structure, and the wave-shaped structure can increase the contact area with the steam; When flowing between the disc 413 and the second disc 414, the heating speed of the first disc 413 and the second disc 414 is accelerated.

[0040] As an embodiment of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com