Automatic part loading device and automatic part loading method

A technology for automatic feeding and parts, applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems of short circuit danger, low work efficiency, high labor cost, etc., to reduce the risk factor, ensure accuracy, and solve problems The effect of low reclaiming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

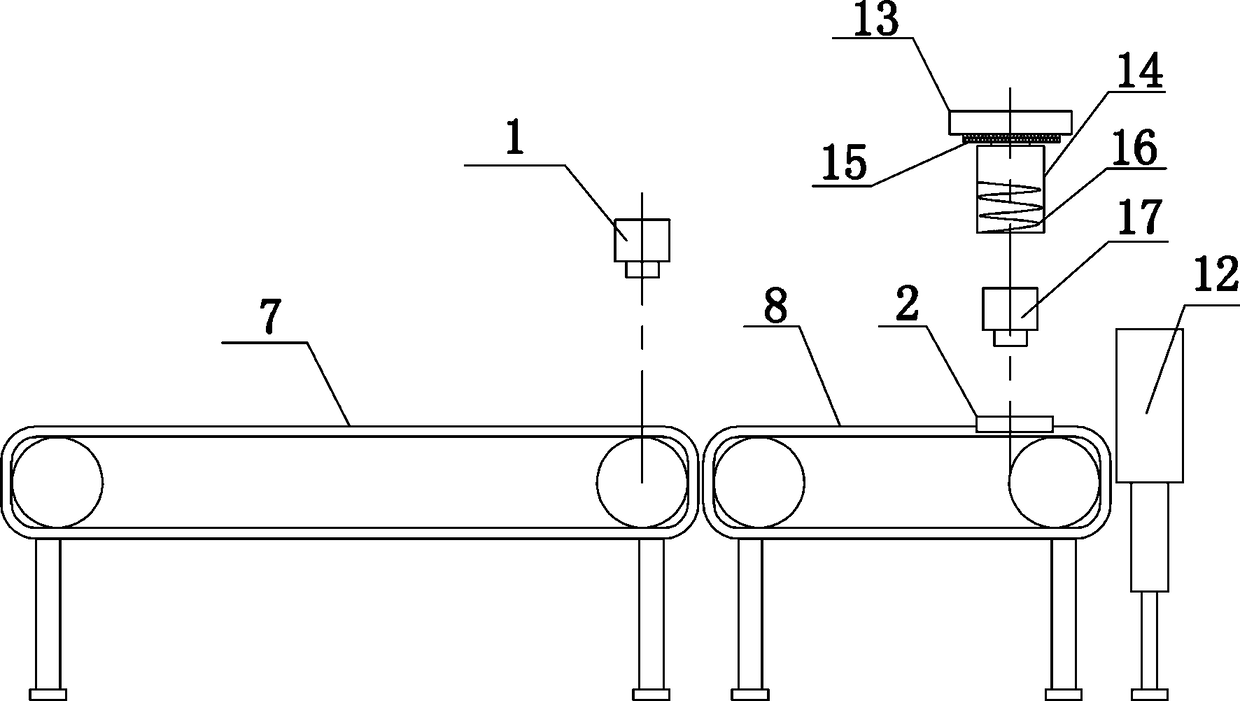

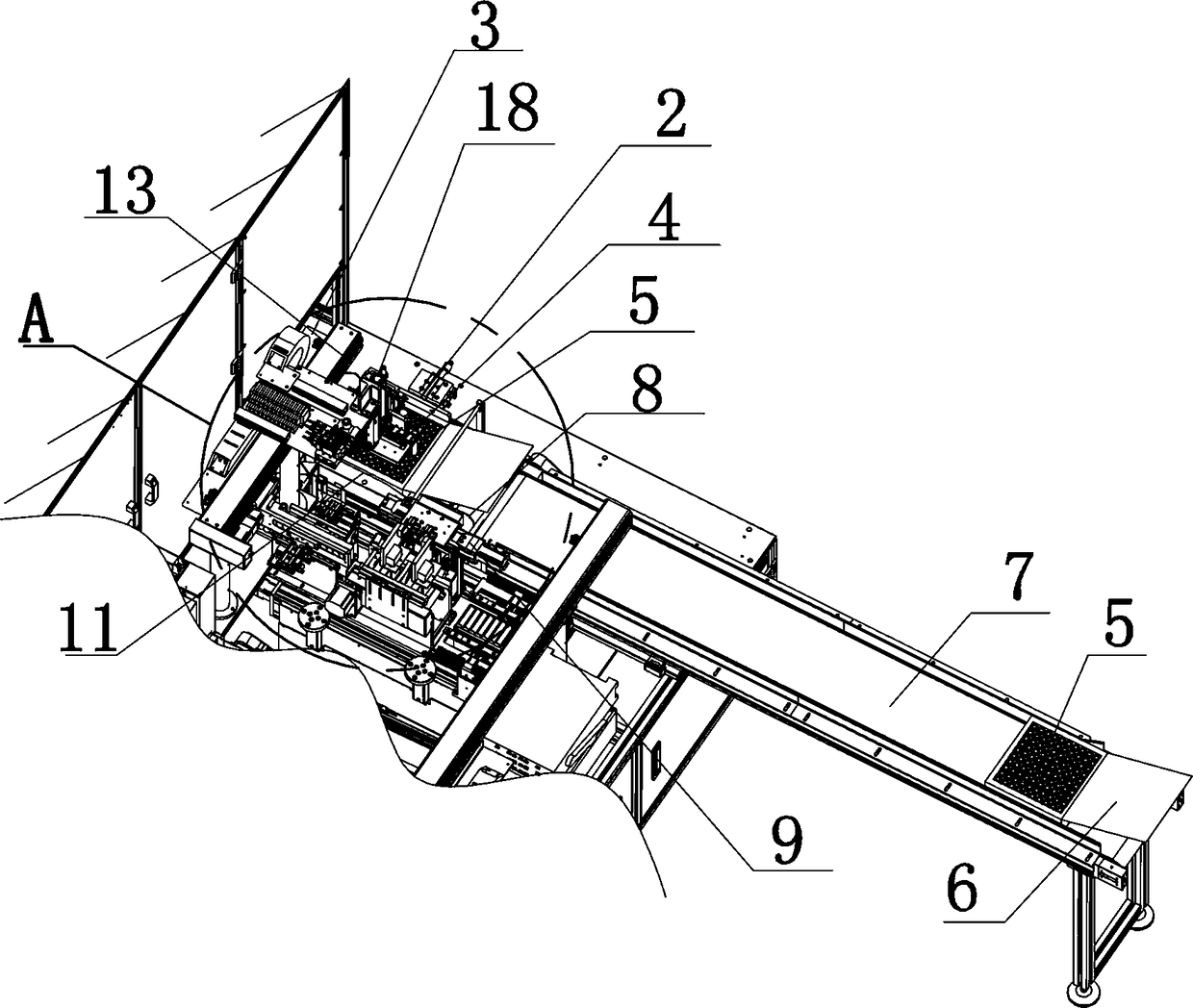

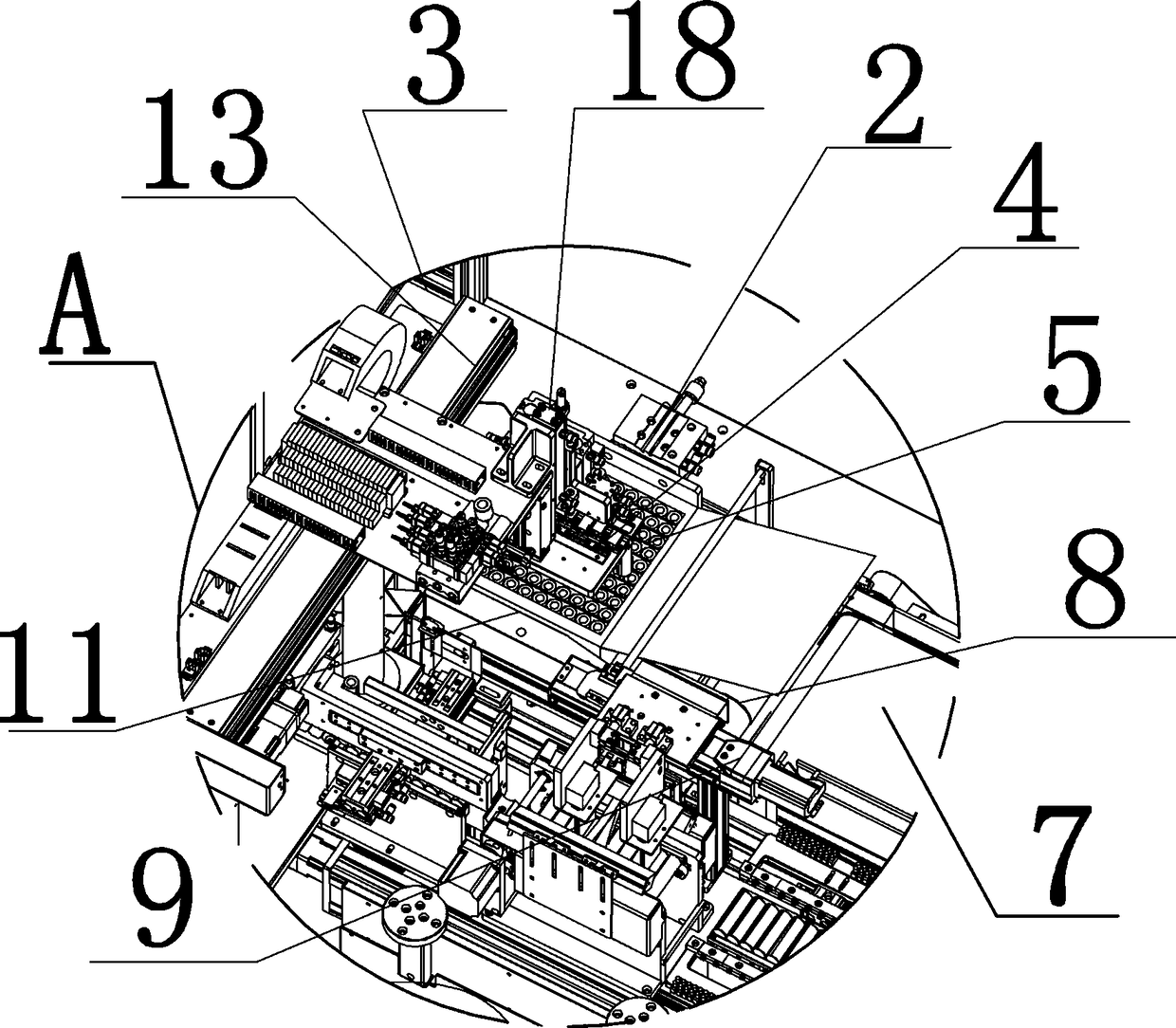

[0033] The invention relates to an automatic parts feeding device, the feeding device includes a conveyor belt, the side of the conveyor belt is sequentially equipped with a feeding detection mechanism 1 and a feeding positioning mechanism 2, The end is provided with a feeding blocking mechanism 3; the feeding device also includes a retrieving mechanism 4 cooperating with the feeding positioning mechanism 2; the conveyor belt, the feeding detection mechanism 1, the feeding positioning mechanism 2, the feeding blocking mechanism Mechanism 3 and reclaiming mechanism 4 are connected to the controller.

[0034] In the present invention, some necessary conditions must first be met, including: the parts 5 to be reclaimed are regularly arranged in the carton 6 and the parts 5 have no special special-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com