Automatic sealing device for packaging boxes

A packaging box, automatic technology, applied in stamping, printing, etc., can solve the problem of high labor intensity of the operator, and achieve the effects of facilitating assembly line operations, improving quality, and ensuring the quality of stamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

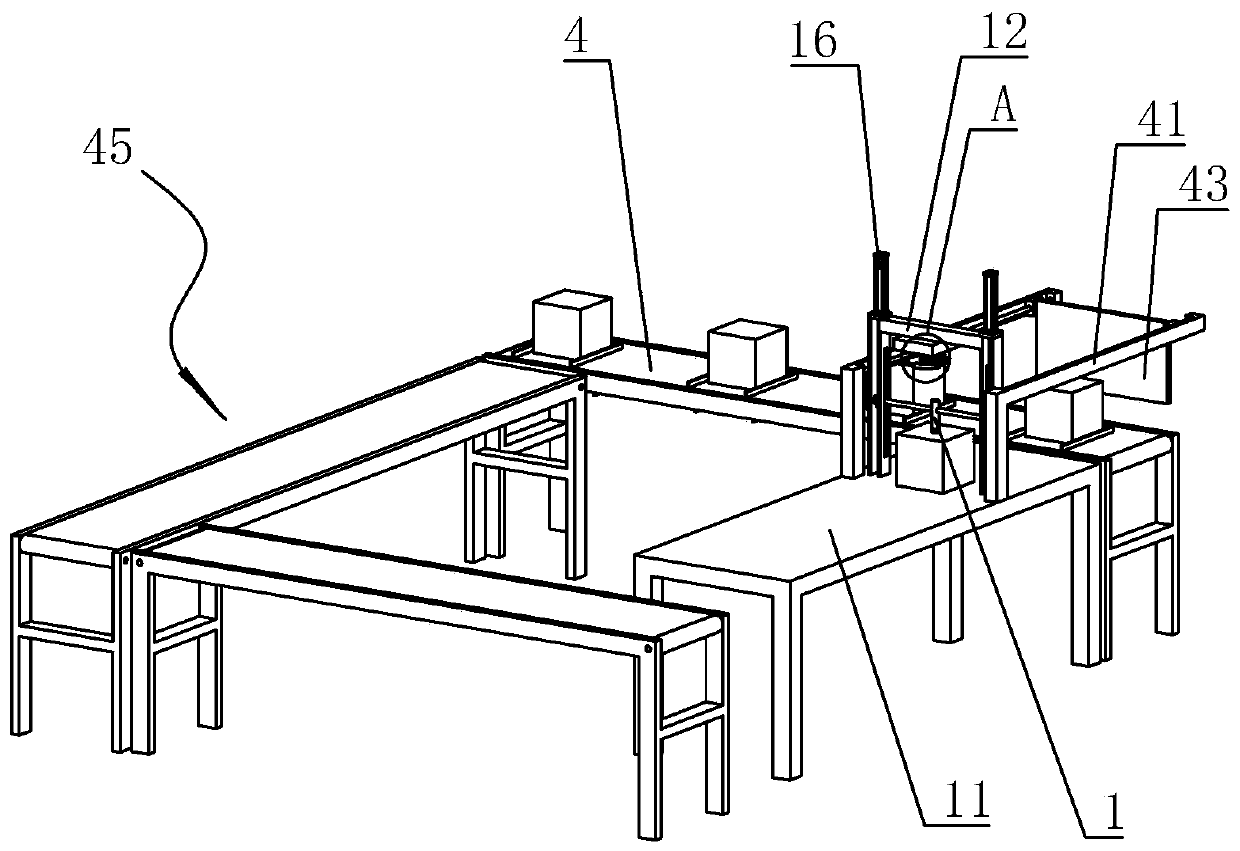

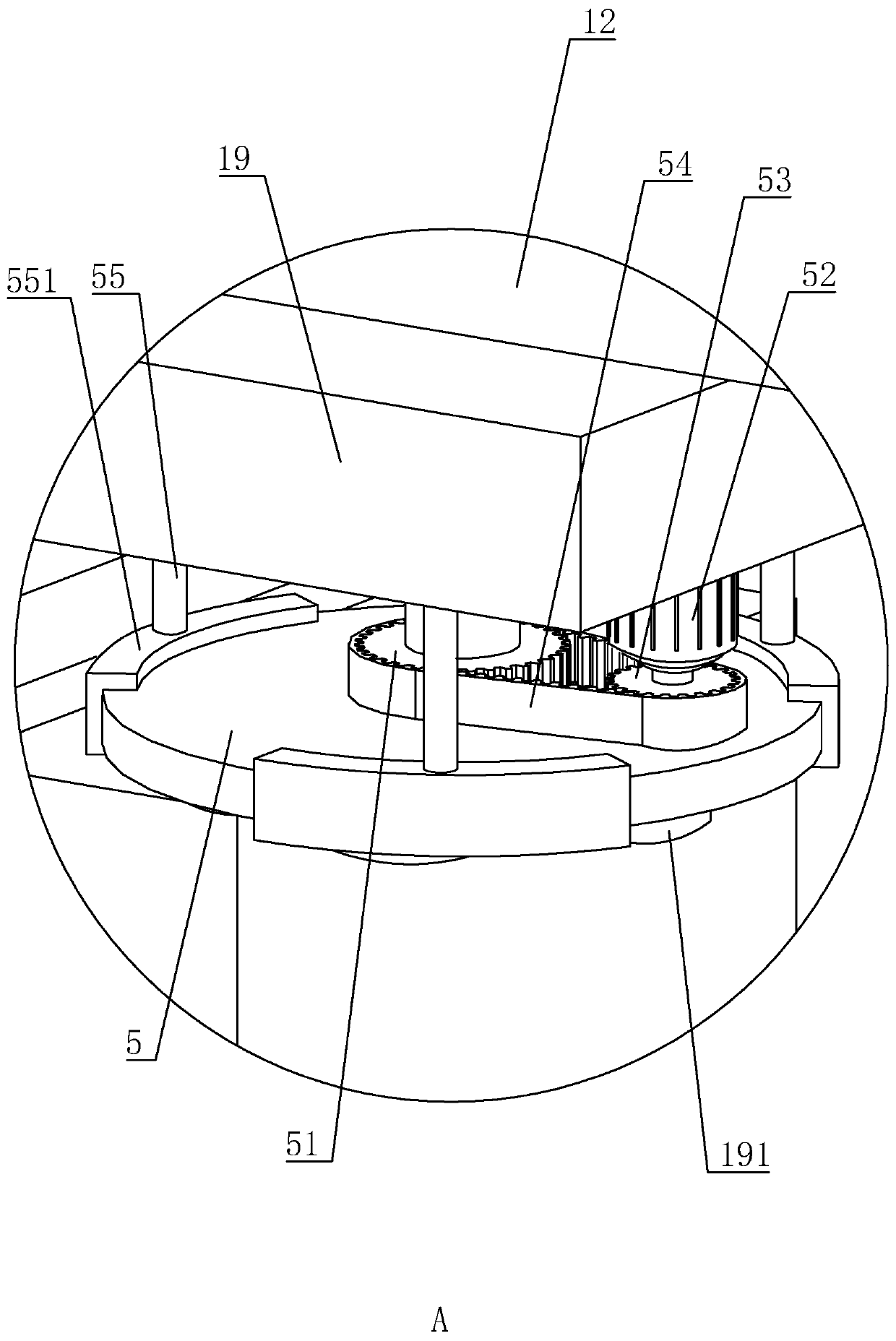

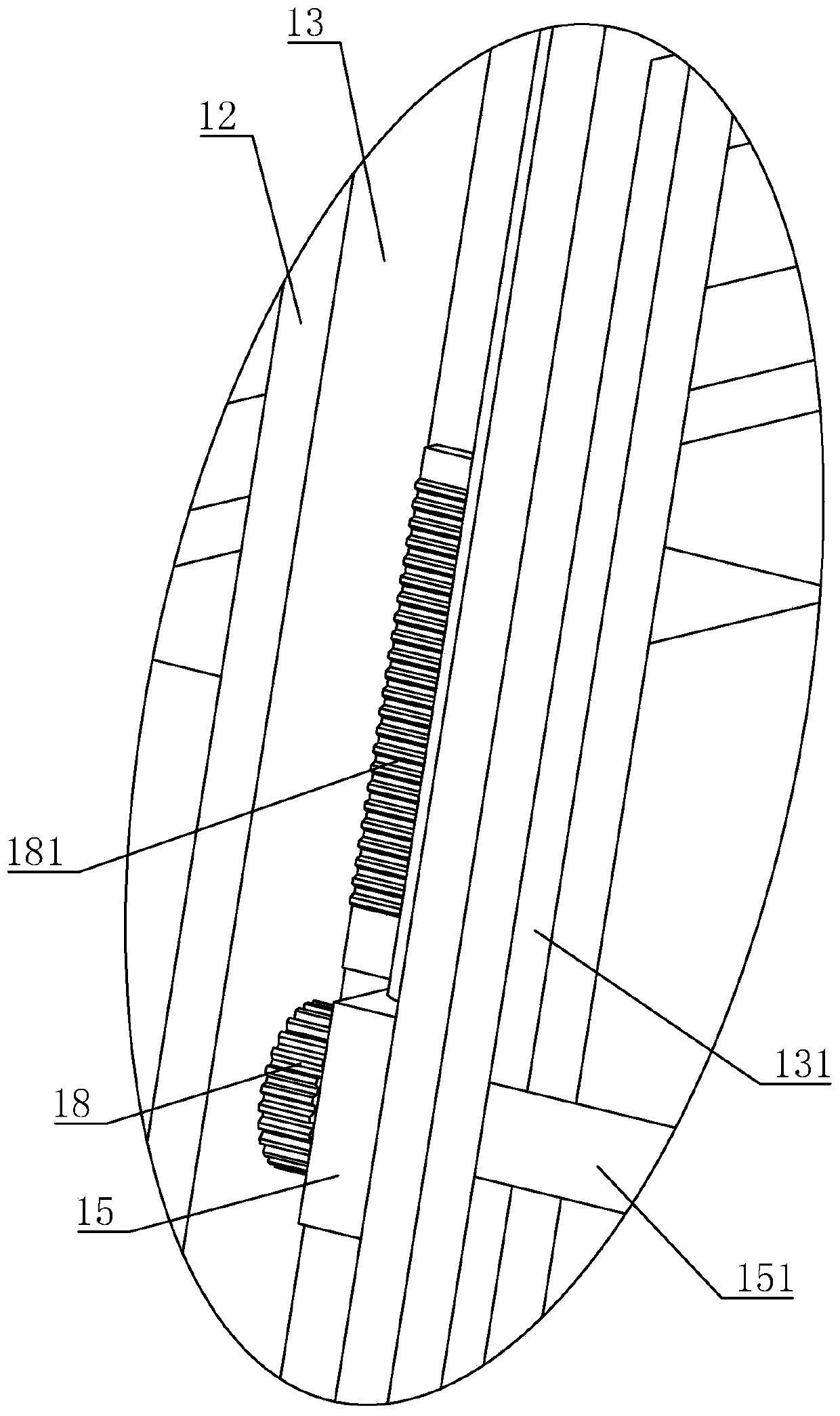

[0040] Embodiment: a kind of automatic sealing device of packing box, as figure 1 with Figure 4 As shown, it includes a seal 17, a drive column 1, a workbench 11, a cylinder 16 and a base frame 12. The base frame 12 is in the shape of a door and is arranged on the workbench 11. The packaging box is placed on the workbench 11 and is located on the base frame 12 In the opening; the base frame 12 is provided with through grooves 13 extending in the vertical direction on both sides of the packing box, and the first slide block 14 and the second slide block 15 are slidably connected in the two through grooves 13 respectively. The opposite sides of the block 14 and the second slide block 15 are respectively rotatably connected with a first central shaft 141 and a second central shaft 151, and one end of the first central shaft 141 and the second central shaft 151 passes through the base frame 12, and passes through One end of the drive column 1 is connected with the drive column 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com