An automatic identification device

A marking device and driving device technology, applied in printing, stamping, etc., can solve problems such as easy movement of the stamping mechanism, hard impact of the circuit board, damage to the stamped object, etc., to achieve reliable guidance, simple structure, and freedom from wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

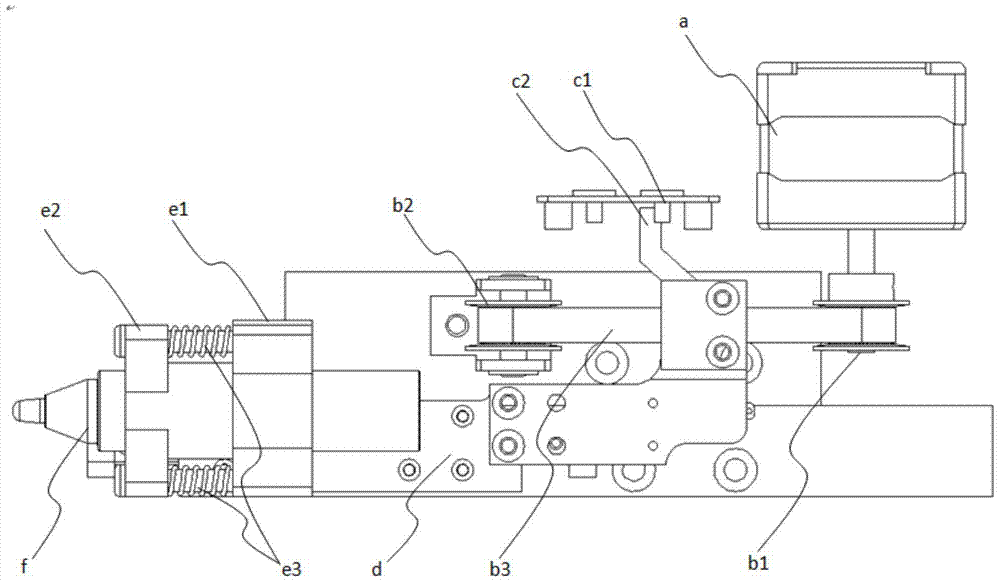

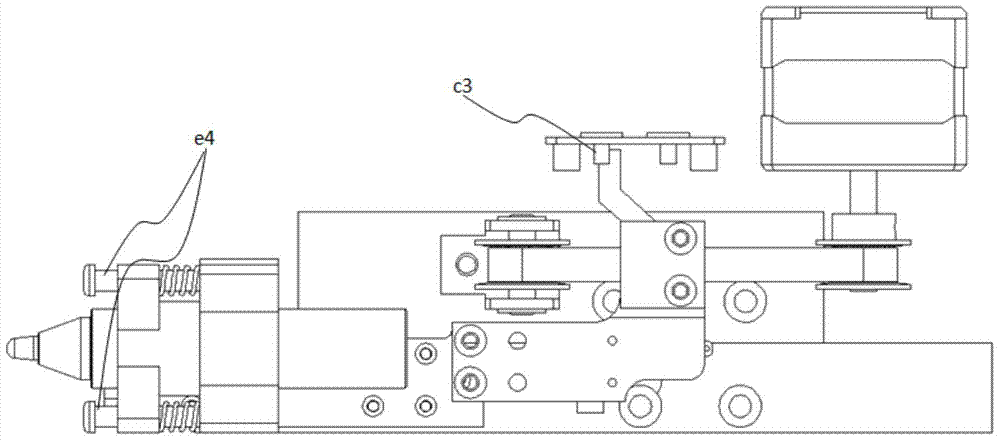

[0030] like Figure 1-2 As shown, a kind of automatic marking device of the present embodiment includes: a marking mechanism with a marking member f; a driving device that drives the marking mechanism to move back and forth; the marking mechanism also includes a The fixed seat e1 can move back and forth in a straight line and is arranged on the movable seat e2 on the fixed seat e1, the identification part f is installed on the movable seat e2, and the fixed seat e1 and the movable seat e2 A biasing component is installed between them, and the biasing force of the biasing component acts on the movable seat e2, so that the movable seat e2 has a tendency to move along the marking direction. In this embodiment, the identification part f is a seal, and the identification mechanism is a seal mechanism. Of course, in other embodiments, the identification part f can also be an oil-based pen, etc., which can be marked on paper or circuit boards. other structures. In the following, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com