Semi-automatic deburring device

A deburring and semi-automatic technology, which is applied in the field of ring gear processing, can solve the problems of potential safety hazards, low work efficiency, and high labor intensity, and achieve the effects of saving gear deburring time, low cost, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

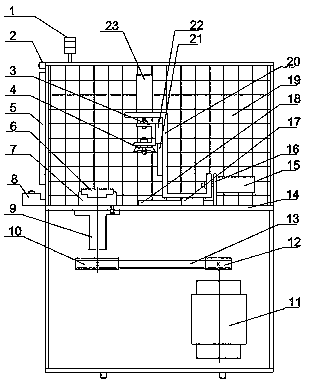

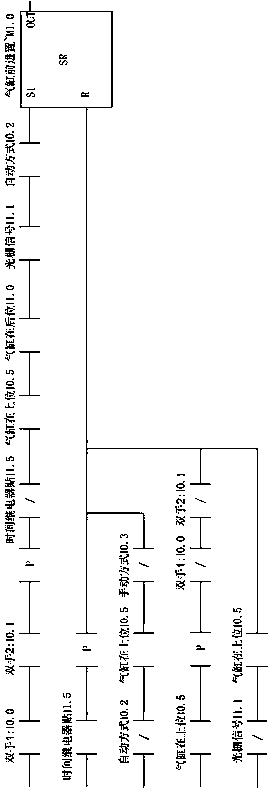

[0016] Such as Figures 1 to 2 As shown, the present invention proposes a semi-automatic deburring equipment, including a workbench 14, a connection seat 9 is provided under one end of the workbench 14, a large pulley 10 is arranged and connected to the bottom of the connection seat 9, and a belt 13 is installed on the outside of the large pulley 10 , the other end of the belt 13 is connected to the small pulley 12, the lower end of the small pulley 12 is connected to the drive shaft of the motor 11, a fixed tooling 7 is fixed directly above the connecting seat 9, the fixed tooling 7 fixes the ring gear 6, and the fixed tooling 7 It is connected with the ring gear 6 model, and the upper end of the workbench 14 is provided with a cylinder fixing plate 16 and a horizontal guide rail 18. The upper end of the slider 17 is provided with a Z-shaped connecting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com