Flexible production line for refrigerator shell

A flexible production line and shell technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of shell material, material thickness, labyrinth groove shape cannot be changed, and work is cumbersome, etc., to achieve flexible force application and large bending space , the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is further described below in conjunction with embodiment.

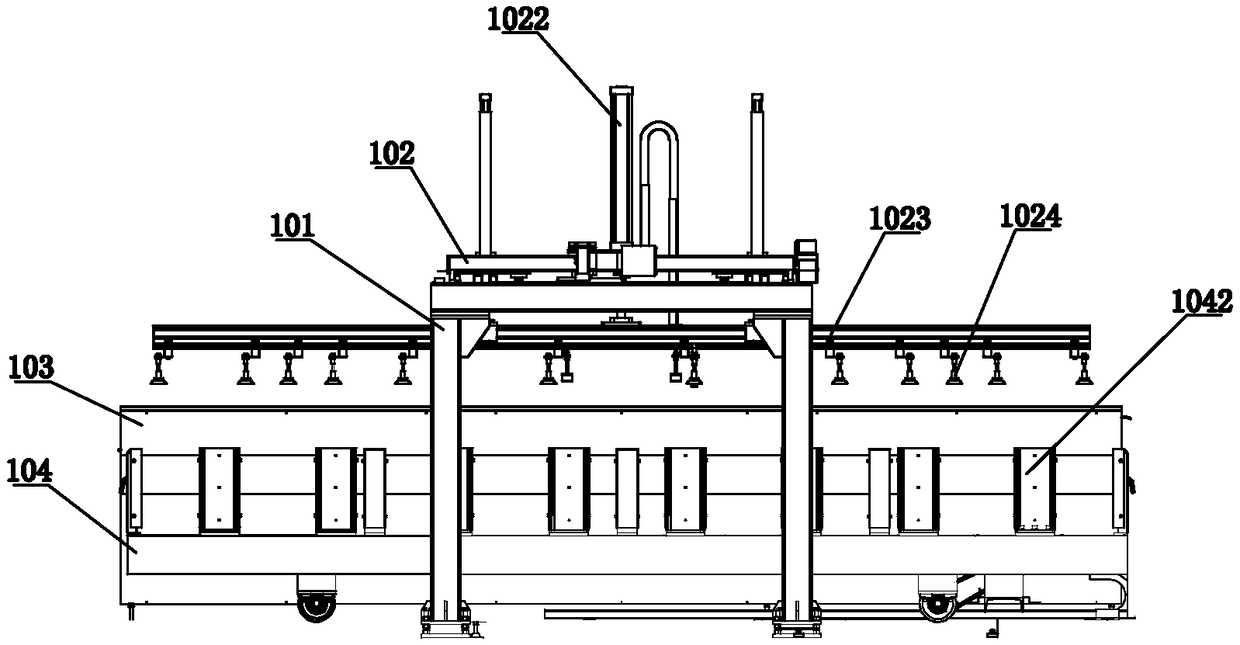

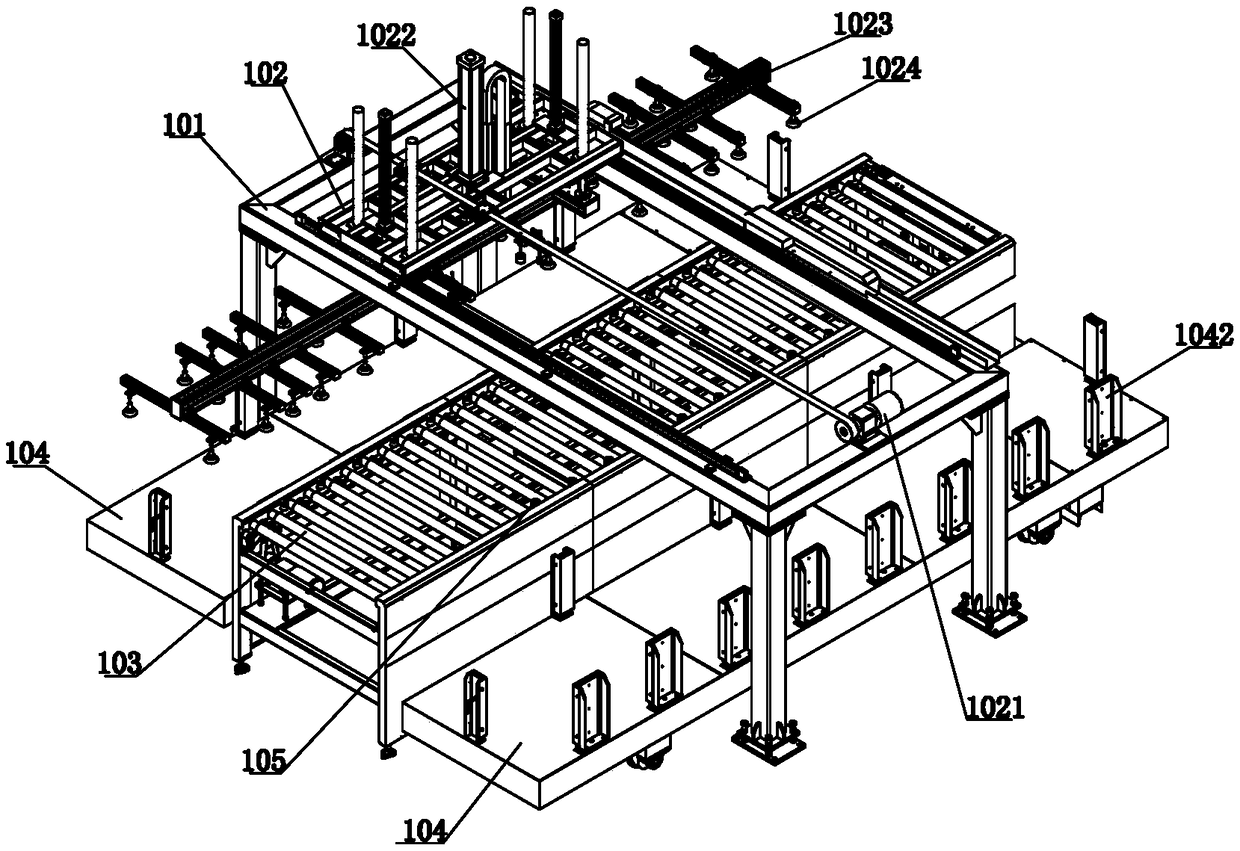

[0040] Such as figure 1 As shown, the flexible production line for refrigerator shells in this embodiment is sequentially equipped with a feeding machine, a punching machine, a 180-degree turning machine, a flexible bending machine, a conveyor belt conveyor line for applying condensers, Z-shaped and L-shaped bending machines, U-shaped bending machine and unloading manipulator.

[0041] Such as Figures 8 to 11 As shown, the flexible bending machine includes a base 401, a delivery platform 410 and two shoulder seats 402, the delivery platform 410 is installed in the middle of the base 401 and extends along the length direction of the base 401, and the two shoulder seats 402 are symmetrically installed on the delivery platform 410, and can move along the width direction of the base 401. On the shoulder 402, there are brackets 403, binders 404 and bending brackets 406. The brackets 403, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com