Opening-closing-type profile drawing mould

A technology of opening and closing, profiles, applied in the direction of wire drawing dies, etc., can solve the problems of difficult mold operation, reduce the chance of being scratched, ensure that it is not scratched, and achieve the effect of good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

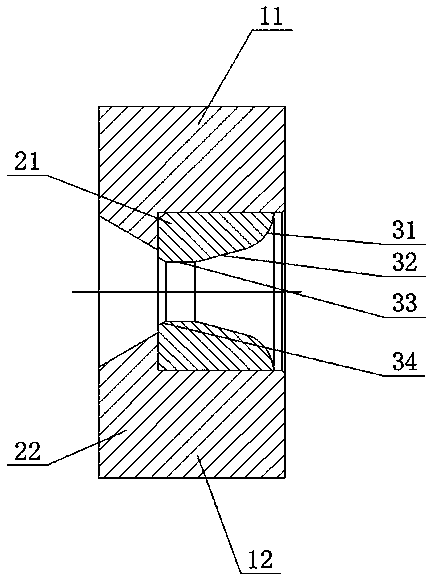

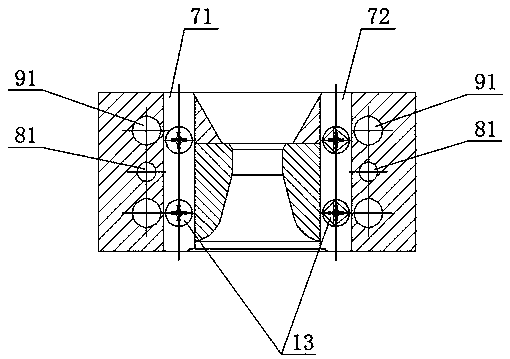

[0023] Such as Figure 1-Figure 4 As shown, a kind of open-close type profile drawing die of the present invention comprises die cover 1, and described die cover 1 is made up of upper die cover 11 and lower die cover 12, and described upper die cover 11 and lower die cover 12 are all It is a semicircular structure and matched with each other. A mold core 2 is installed in the mold cover 1. The mold core 2 is composed of an upper mold core 21 and a lower mold core 22. The upper mold core 21 and the lower mold core 22 are semi-circular structures and match each other, the upper mold core 21 is installed in the upper mold sleeve 11, the lower mold core 22 is installed in the lower mold sleeve 12, and a variable diameter channel is provided in the center of the mold core 2 3. A left upper die sleeve groove 41 and a right upper die sleeve groove 42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com