Water spray mop

A technology of mop and mop rod, which is applied in the direction of cleaning carpets, floors, cleaning equipment, etc., which can solve the problems of inconvenience, affecting efficiency, and long distance, and achieve the effect of convenient use and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

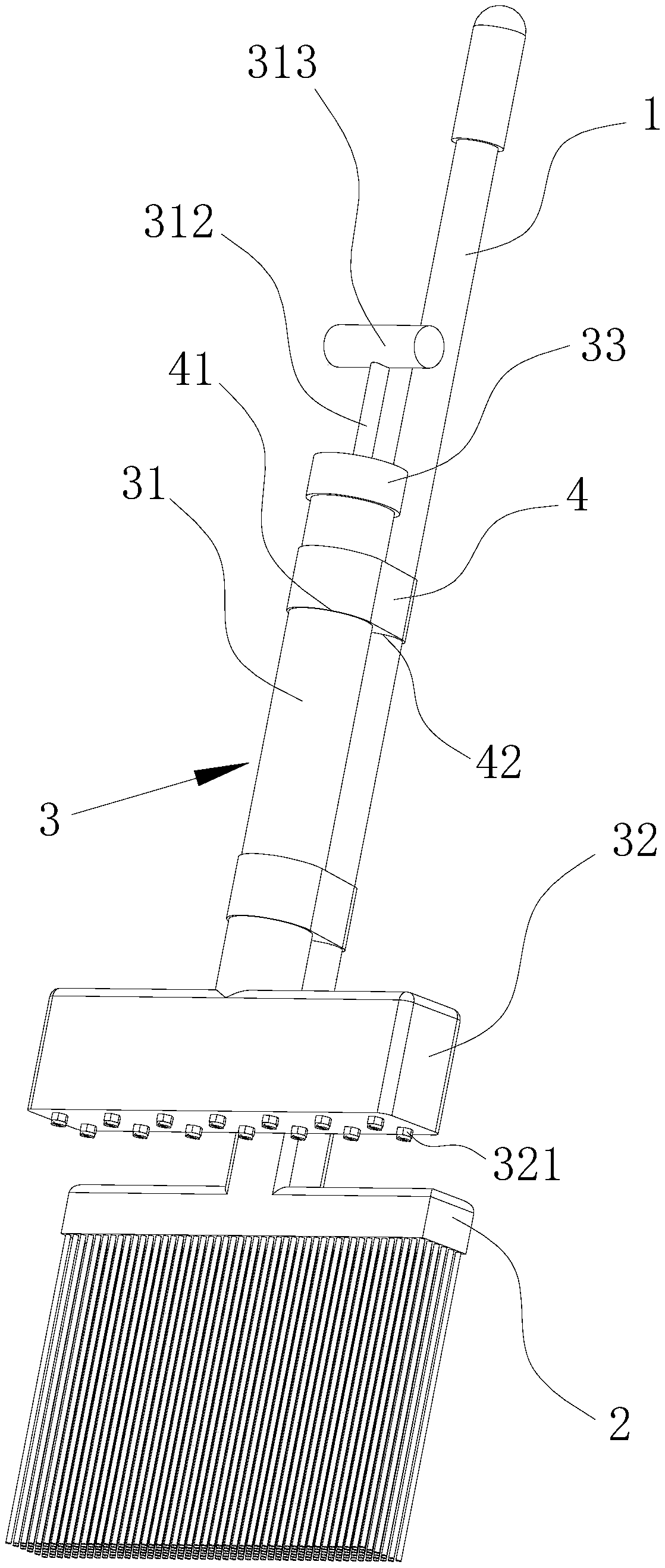

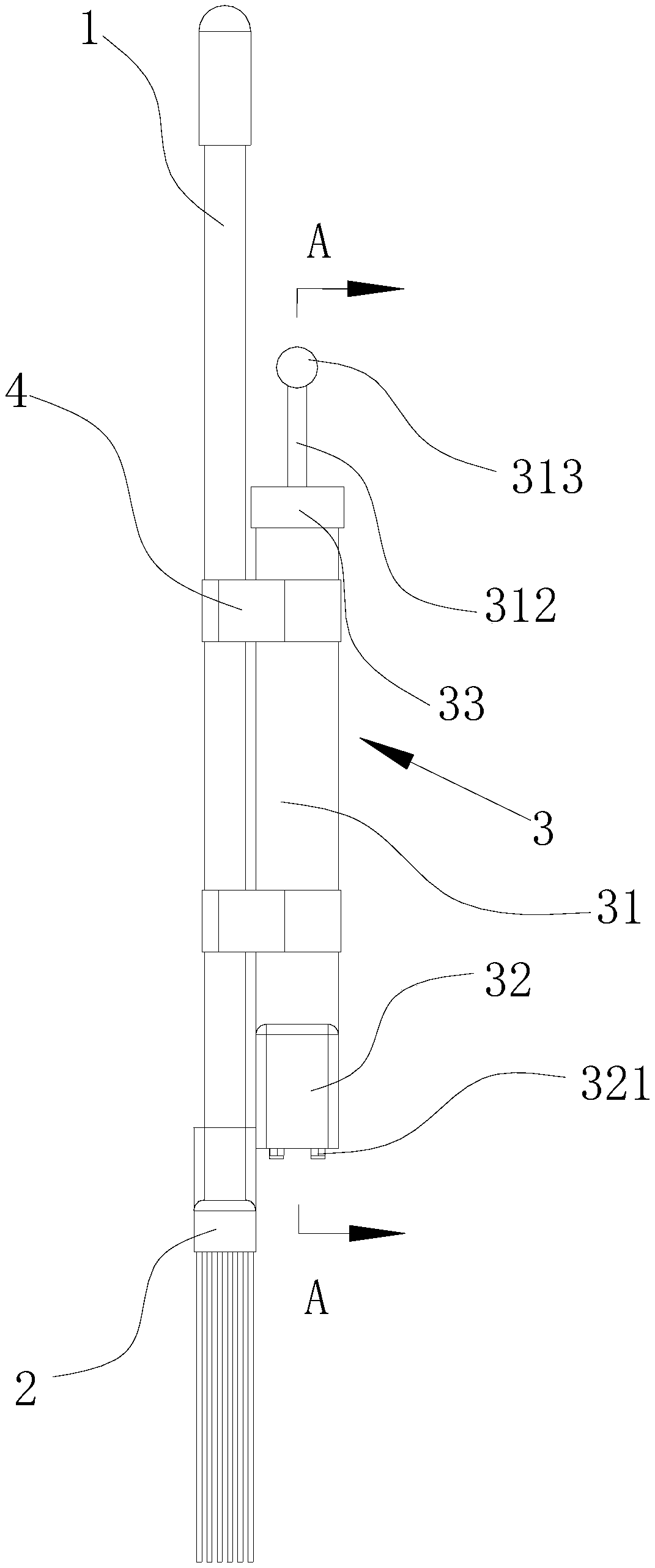

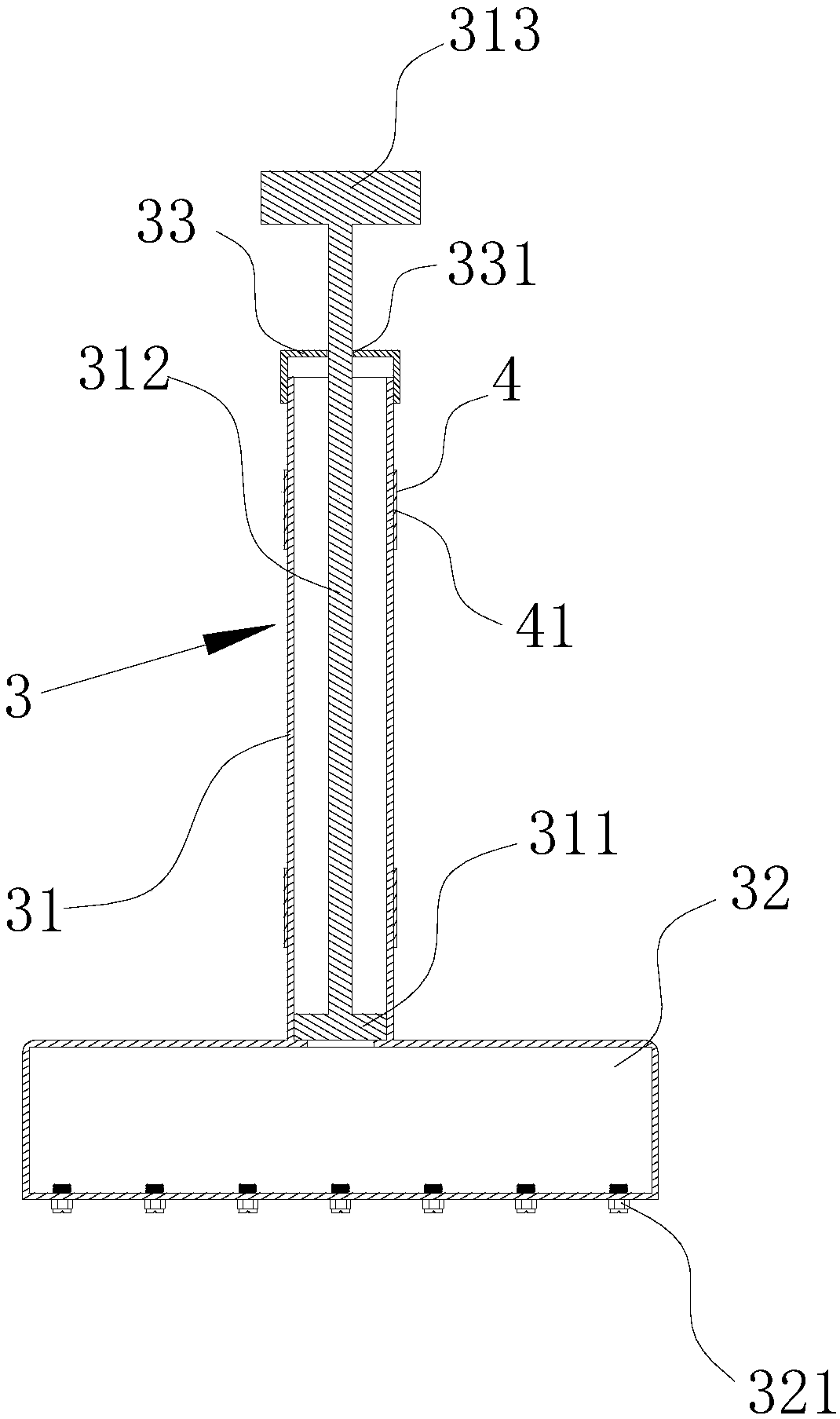

[0017] see Figure 1-Figure 4 , a water spray mop, comprising a vertically arranged mop bar 1, the lower side of the mop bar 1 is provided with a horizontally arranged elongated mop brush head 2, and also includes a water spray device 3, and the water spray device 3 includes Air cylinder 31, water storage box 32, the air cylinder 31 is a cylindrical barrel arranged vertically, the shape of the water storage box 32 is a long strip, the length direction of the water storage box 32 is consistent with the length direction of the mop brush head 2, and the water storage Both sides of box 32 length direction are corresponding flush with mop brush head 2 length direction both sides, and water storage box 32 is located at the downside of gas cylinder 31, and water storage box 32 downsides are provided with some water outlet holes (due to atomizing nozzle 321 among the figure). block the water outlet hole, so the water outlet hole is not marked with a part number), the water outlet hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com