Fig shortbread and preparation method thereof

A technology of figs and production methods, which is applied in the direction of baking, baked food with modified ingredients, dough treatment, etc., can solve the problems of weakening the health value of figs, low nutritional value, and incomplete health care functions, so as to reduce nutrient loss, Enhance health care efficacy and increase the effect of health care function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A fig crisp is composed of the following raw materials in parts by weight: 8 parts of wheat flour, 3 parts of white sugar, 22 parts of butter, 2 parts of egg powder, 2.0 parts of water, 55 parts of fig stuffing and 8 parts of licorice powder.

[0023] In the present embodiment, the preparation method of fig stuffing comprises the following steps: (1) Screening and cleaning fresh figs, removing pits and separating the pulp, adding pectinase solution diluted with water to the pulp, and finally heating the figs at 25°C and pH 3.0 The enzymolysis reaction was carried out for 20 minutes under the environment; the mass ratio of added water to pulp was 1:1, and the mass ratio of pectinase to water was 1:10000; (2) firstly, the enzymolyzed pulp was sent into a screw extruder to obtain Broken fig pulp; then the fig pulp is sent into the grinder for secondary crushing and mixing, and finally the mixed slurry is filtered with 100 mesh screens to obtain the fig pulp, and the filter ...

Embodiment 2

[0027] A fig crisp is composed of the following raw materials in parts by weight: 7 parts of wheat flour, 4 parts of white sugar, 25 parts of butter, 3 parts of egg powder, 2 parts of water, 50 parts of fig stuffing and 9 parts of licorice powder.

[0028] In the present embodiment, the preparation method of fig stuffing comprises the following steps: (1) Screening and cleaning fresh fig fruits, removing the pits and separating the pulp, adding pectinase solution diluted with water to the pulp, and finally adding the pectinase solution diluted with water to the pulp at 40°C and having a pH of 4.0 The enzymolysis reaction was carried out for 95 minutes under the environment; the mass ratio of added water to pulp was 2:1, and the mass ratio of pectinase to water was 1:25000; (2) firstly, the enzymolyzed pulp was sent into a screw extruder to obtain Broken fig pulp; then the fig pulp is sent into the grinder for secondary crushing and mixing, and finally the mixed slurry is filter...

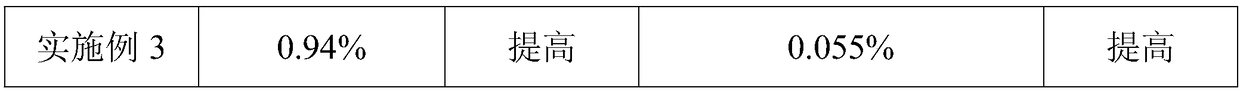

Embodiment 3

[0032] A fig cake is composed of the following raw materials in parts by weight: 9 parts of wheat flour, 2 parts of white sugar, 20 parts of butter, 1 part of egg powder, 2 parts of water, 60 parts of fig stuffing and 6 parts of licorice powder.

[0033] In the present embodiment, the preparation method of fig stuffing comprises the following steps: (1) Screening and cleaning fresh fig fruit, removing the core and separating the pulp, adding pectinase solution diluted with water to the pulp, and finally adding the pectin enzyme solution diluted with water to the pulp, The enzymolysis reaction was 170 minutes under the environment; the mass ratio of added water to pulp was 3:1, and the mass ratio of pectinase to water was 1:40000; (2) firstly, the enzymolyzed pulp was sent into a screw extruder to obtain Broken fig pulp; then the fig pulp is sent into the grinder for secondary crushing and mixing, and finally the mixed slurry is filtered with a 120 mesh screen to obtain the fig ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com