Cow feeding device and method with good cleanliness

A clean, lifting device technology, applied in the field of animal husbandry, can solve the problems of feed waste, cattle malnutrition, etc., and achieve the effects of reducing labor intensity, saving feed, and ensuring feed safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

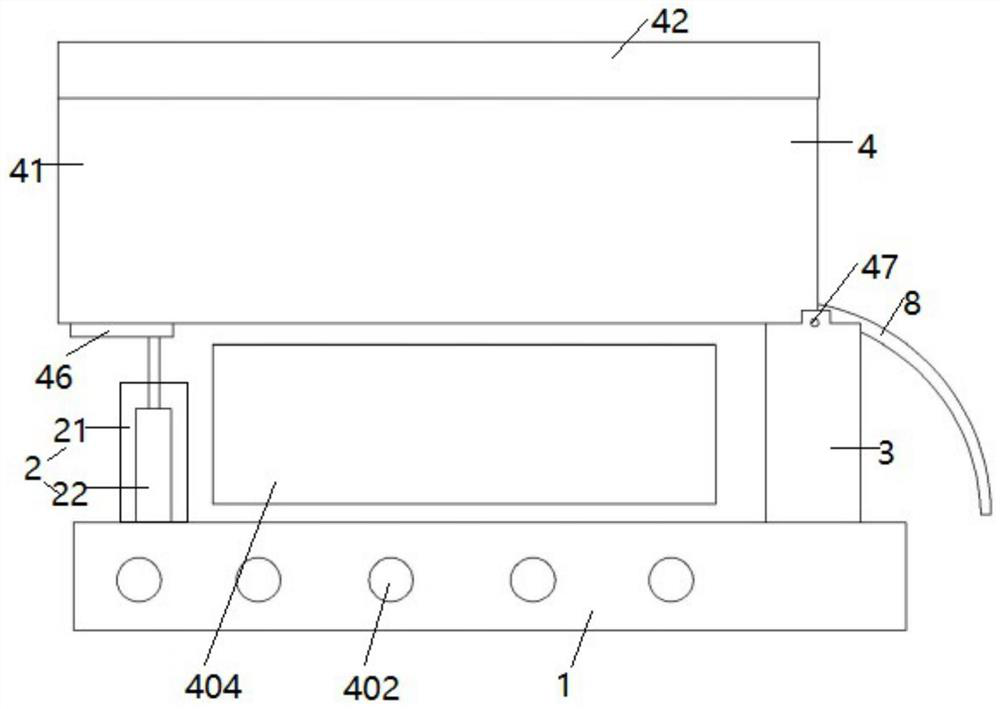

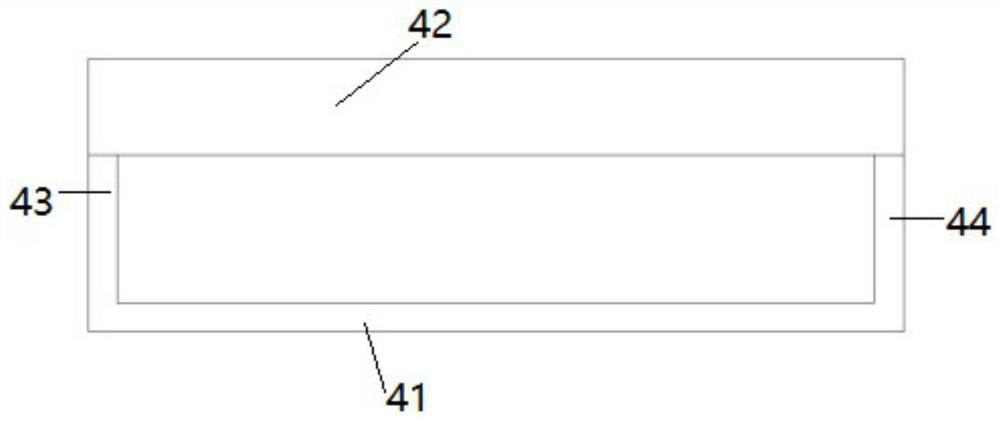

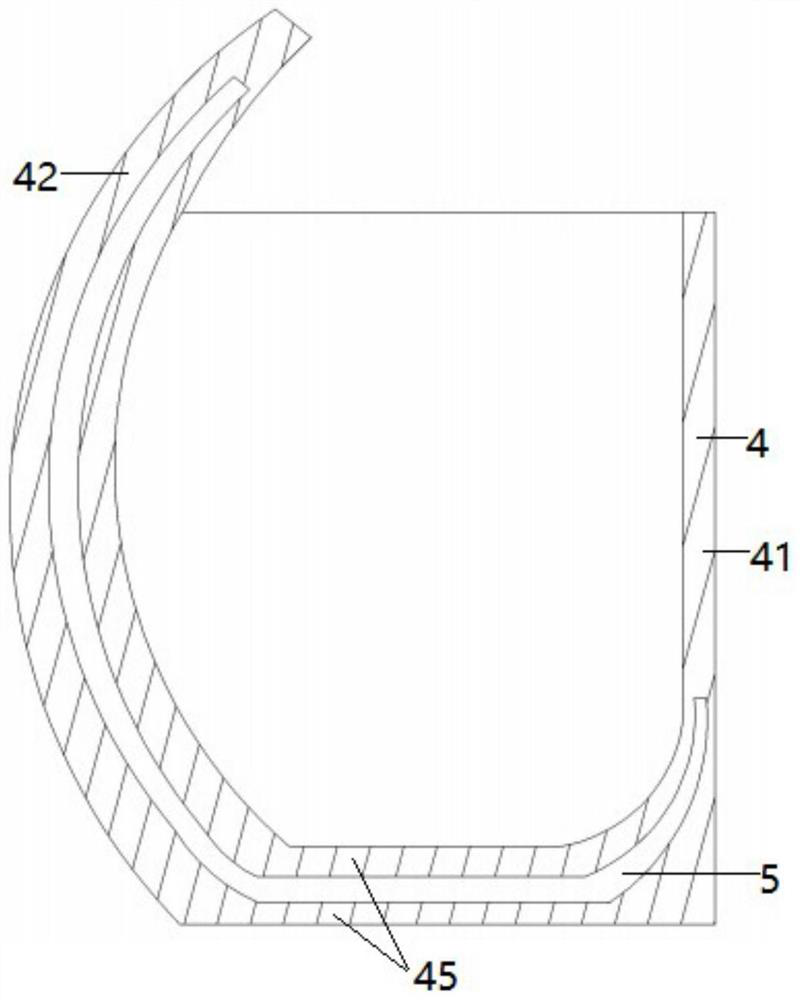

[0038] Such as figure 1 The shown embodiment is a cow feeding device with good cleanliness, including a base 1, a left support frame 2 and a right support frame 3 arranged on the base, and the horizontal sections arranged on the left support frame and the right support frame are rectangular trough 4; such as figure 2 , image 3 As shown, the trough includes a front side wall 41, a right side wall 42, a left side wall 43, a rear side wall 44 and a U-shaped bottom plate 45. The height of the position is higher than the height of the positions of the upper ends of other side walls; the rear side wall and the U-shaped bottom plate are provided with a cavity 5, and the rear side wall and the inner surface of the U-shaped bottom plate are provided with a plurality of passages communicating with the cavity. Each through hole is provided with a one-way valve that can spray air from the cavity, and the cavity is connected with the air pump 6 through a pipeline, such as Figure 4 As...

Embodiment 2

[0046] Embodiment 2 includes all structure and method parts of embodiment 1, such as figure 1 Shown, embodiment 2 also comprises the guide pipe 8 that is located on the food trough, is located at the hanging bracket above the food trough, as Figure 5Shown, be located at the water outlet pipe and agitator 9 that can spray water downwards on the hanging bracket; figure 1 As shown, the left support frame includes a vertical cylinder 21 and a vertical cylinder 22 located in the vertical cylinder, and the end of the telescopic rod of the vertical cylinder stretches into a horizontal chute 46 located on the left side of the lower surface of the trough, and the right support frame passes through The rotating shaft 47 is rotationally connected with the lower right part of the food trough; the suspension bracket is connected with the fixture by the lifting device, and the fixture is connected with the water outlet pipe and the agitator respectively, and the water outlet pipe is provid...

Embodiment 3

[0053] Embodiment 3 includes all structure and method parts of embodiment 1, as figure 1 As shown, the base of embodiment 3 is provided with a fan 404, the fan is connected to the base through a column, and the column is provided with a motor for driving the fan to rotate, as Figure 4 As shown, both the fan and the motor 405 are electrically connected to the controller.

[0054] Also include the following steps:

[0055] When the temperature is higher than 25°C, the staff controls the fan to work through the controller, controls the motor to rotate, and makes the air outlet of the fan swing up and down to cool down the cattle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com