Preparation method of conventional poly-crystal secondary printing solar cell

A solar cell sheet and secondary printing technology, which is applied in printing, printing machines, rotary printing machines, etc., can solve the problems of low performance of the cell sheet, improve spectral responsivity, increase absorption rate, and improve grid line printing quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

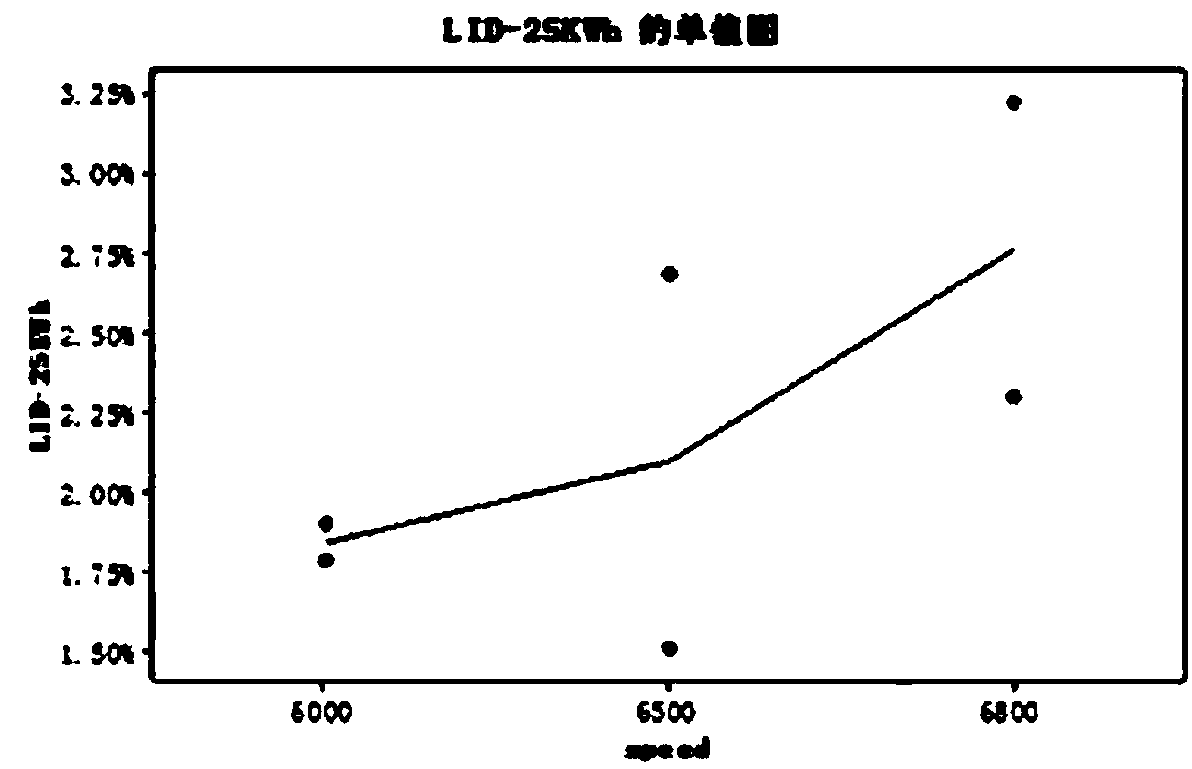

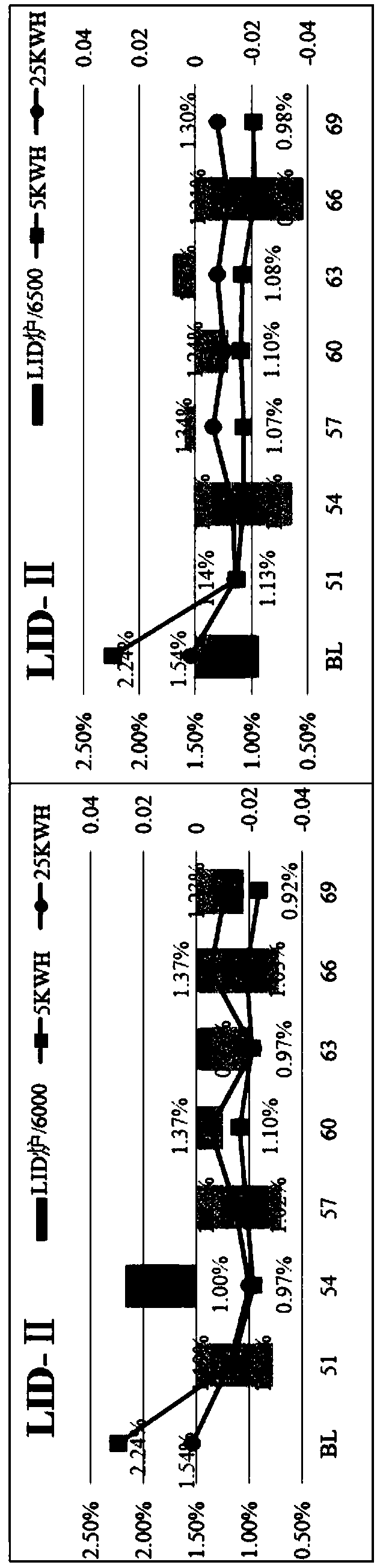

Image

Examples

Embodiment Construction

[0058] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

[0059] The invention provides a method for preparing a conventional polycrystalline secondary printed solar cell, comprising the following steps:

[0060] A. Texturing. Use a mixed solution of HF, HNO3 and pure water to acid-etch the surface of polycrystalline silicon wafers. After acid-etching, the suede surface is microscopically worm-like. Due to the multiple reflections and refractions of incident light on the surface, the light absorption is increased and the performance is improved. The short-circuit current and conversion efficiency of the battery. Among them, the HNO3 concentration is 540-600g / L, the HF concentration is 70-90g / L, and the texturing temperature is 10°C. . In order to obtain a uniform suede surface, alcohols such as ethanol an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com