U-shaped housing and cover concept for plate fin heat exchangers

A technology for heat exchangers and shells, applied in the field of shell configuration of heat exchangers, can solve the problems of joint leakage, increase manufacturing and assembly costs, and complex shells, and achieve minimal leakage, manufacturing and assembly costs. minimized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following detailed description and drawings describe and illustrate various embodiments of the invention. The description and drawings are intended to enable a person skilled in the art to make and use the invention and are not intended to limit the scope of the invention in any way. With respect to the disclosed methods, the steps presented are exemplary in nature, and thus, the order of the steps is not required or critical. As used herein, the term "substantially" means "mainly but not completely" or "approximately" as will be recognized by those skilled in the art from the specification and drawings.

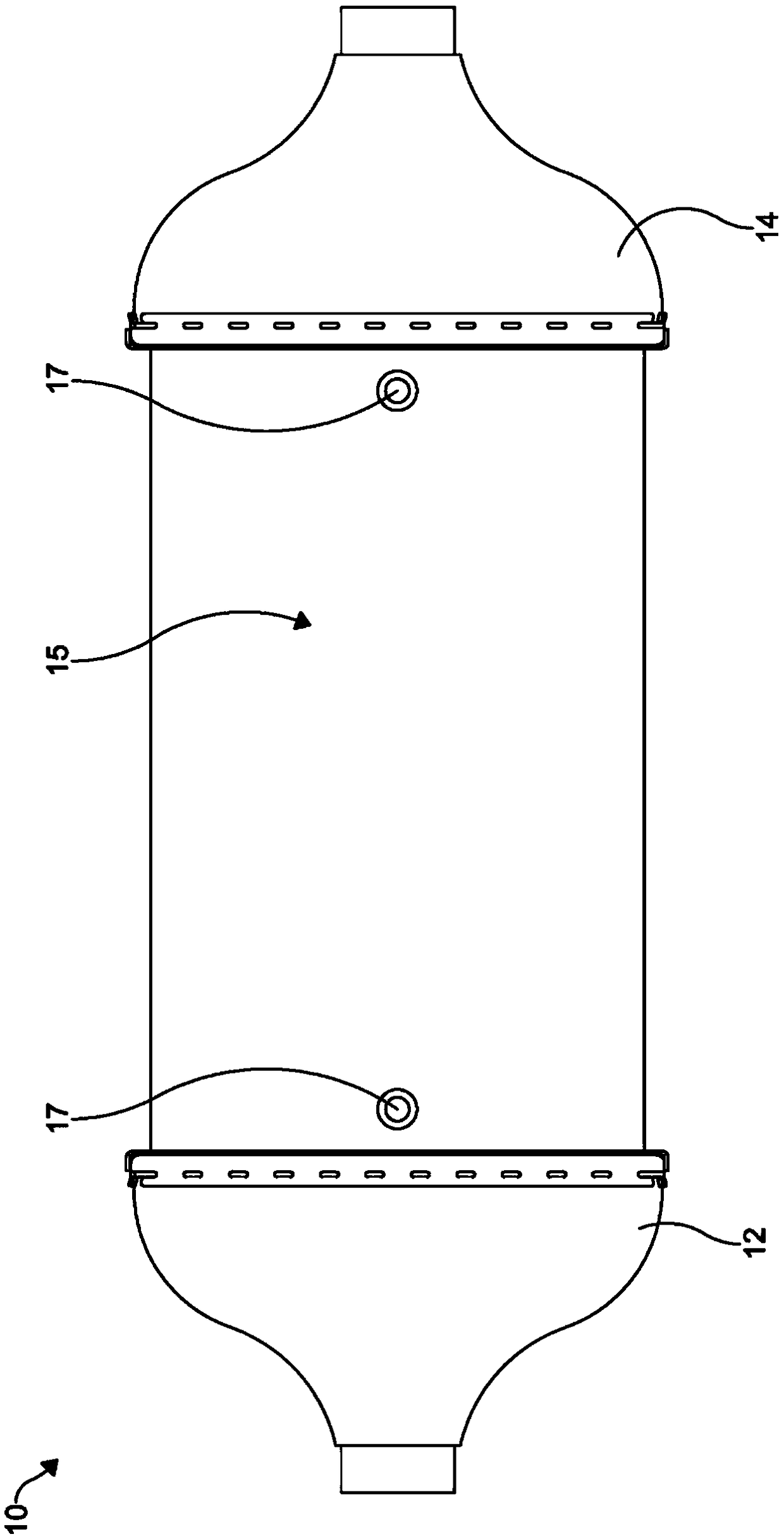

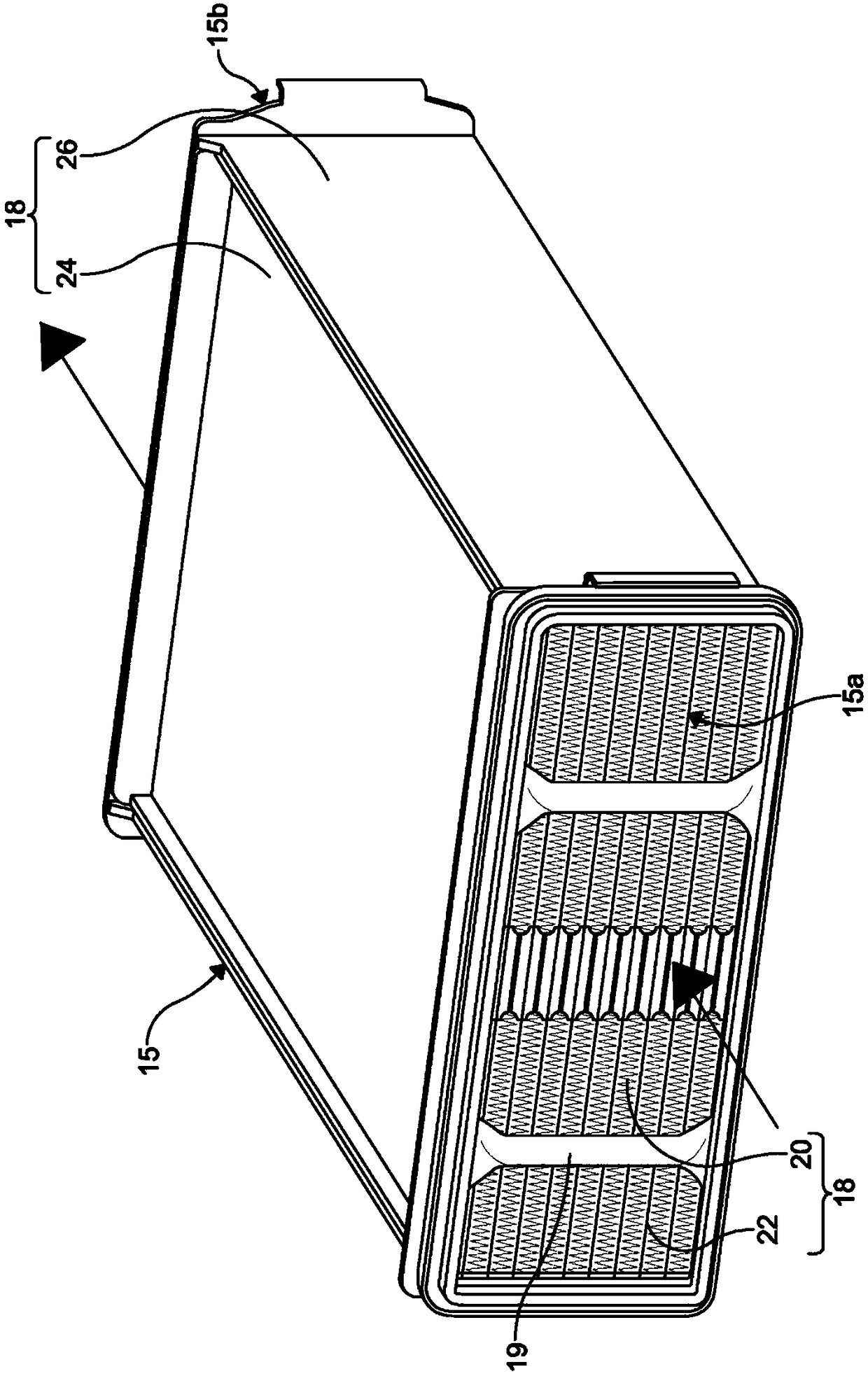

[0016] figure 1 A heat exchanger 10 according to an embodiment of the present disclosure is shown. As shown, the heat exchanger 10 is configured as an intercooler, such as, for example, a water-cooled charge air cooler. However, it will be appreciated that heat exchanger 10 may be configured as any type of heat exchanger commonly used in vehicle systems, such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com