Molten aluminum refining method

A technology of aluminum liquid and smelting furnace, which is applied in the field of aluminum liquid refining, can solve the problems of aluminum liquid tumbling and burning, poor working environment, and low work efficiency, and achieve the effects of avoiding temperature loss, improving refining effect, and reducing burning loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to facilitate understanding of the present invention, the present invention will be described more fully below. However, the present invention may be embodied in many different forms and is not limited to the embodiments described herein. Rather, these embodiments are provided so that a thorough and complete understanding of the present disclosure is provided.

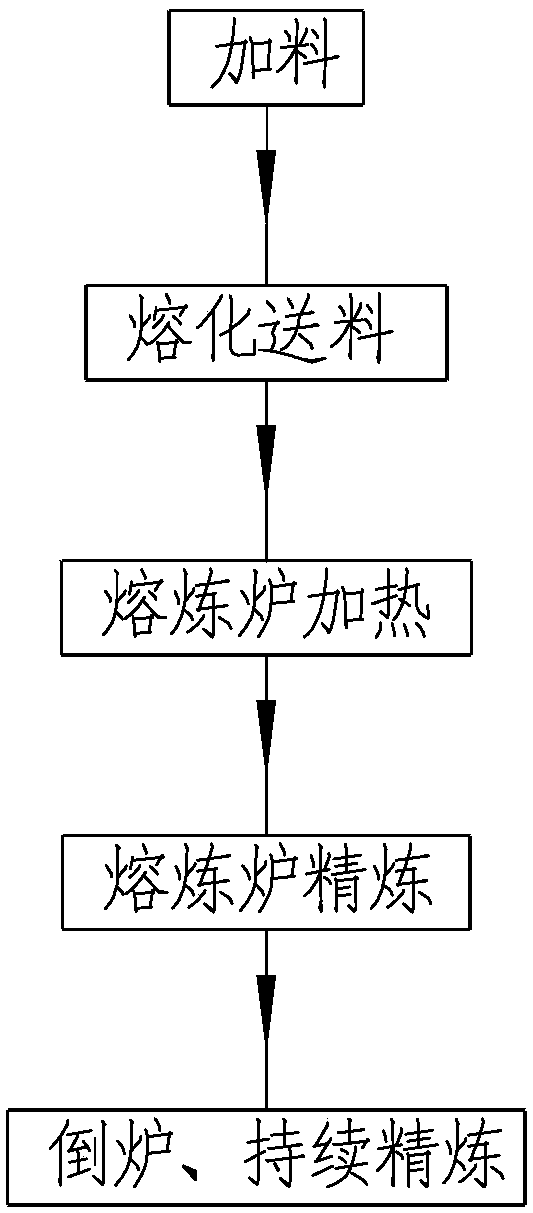

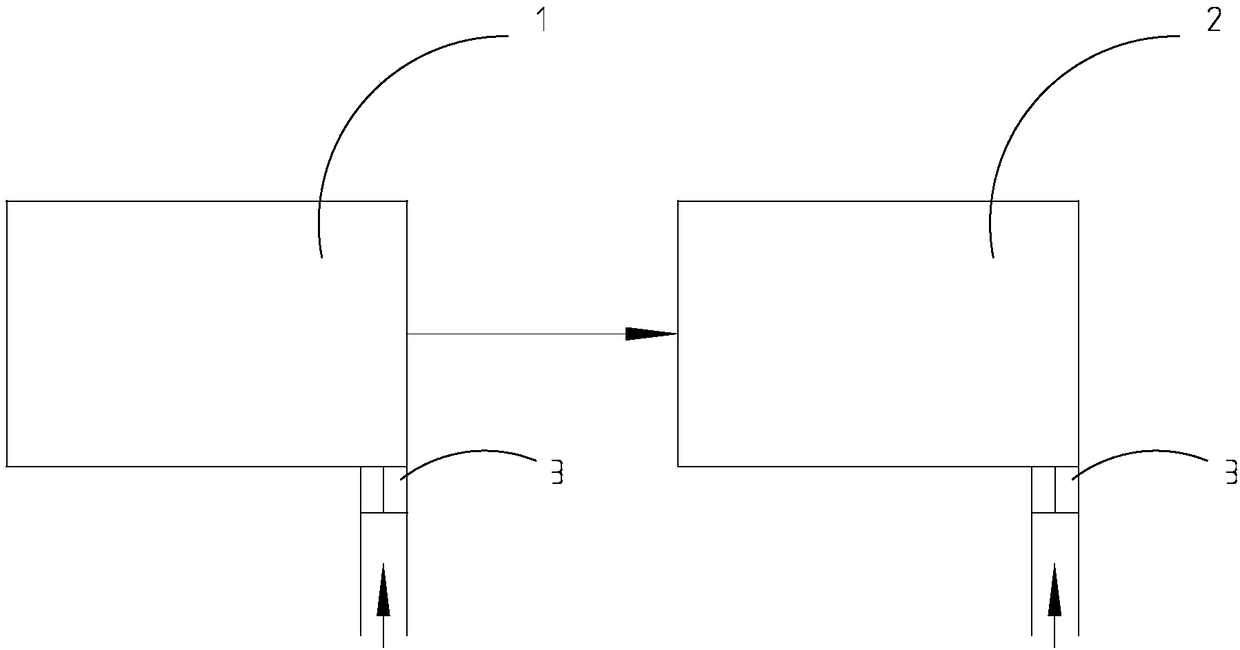

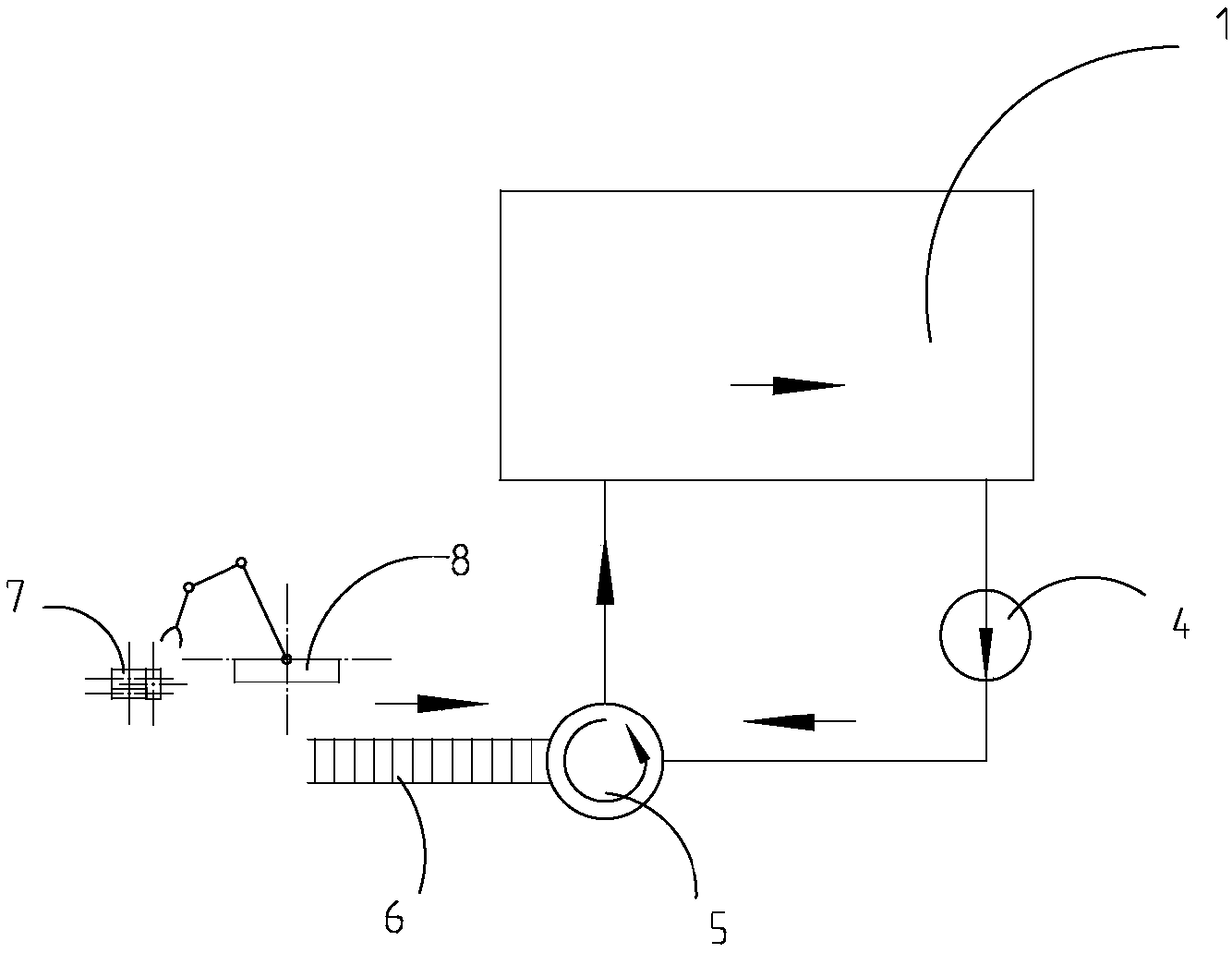

[0045] refer to Figure 1-Figure 3 . A method for refining molten aluminum of the present invention comprises the following steps:

[0046] S1, feeding

[0047] A feeding port is set outside the smelting furnace. After the external feeding port is added, the aluminum liquid circulating pump is used to transport it to the smelting furnace.

[0048] Among them, the feeding adopts the automatic feeding of the manipulator and the slide.

[0049] The feeding is automatically fed by an automatic feeding device. The automatic feeding device includes a slide rail and a manipulator whose one end is placed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com