Small-sized non-vibration rectilinear motion device

A linear motion, small-scale technology, applied in the direction of electromechanical devices, electrical components, etc., can solve problems such as motion accuracy and volume restrictions, affect the safety and stability of motion accuracy, stator and fixed bracket impact, etc., achieve high motion accuracy, eliminate Error and transmission shock, the effect of improving motion accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

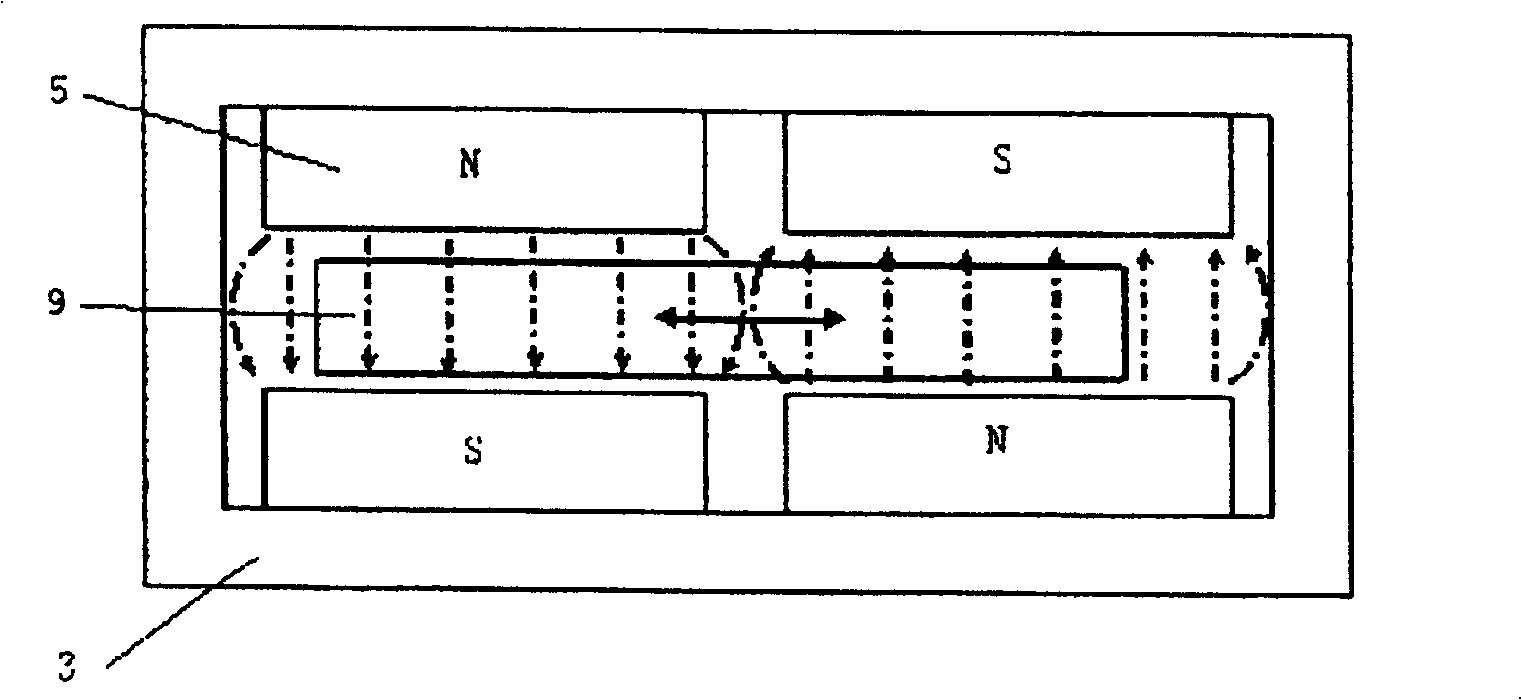

[0024] The small-scale non-vibration linear motion device of the present invention mainly adopts the principle of a linear motor, and uses an energized coil to be directly driven by Lorentz force in a parallel magnetic field to realize linear motion; The active block is connected with the rocker arm and drives the driven block, so that the driven block can move at the same speed, parallel and opposite direction as the active block; the driven block coincides with the center of mass of the active block with equal mass. So as to achieve the purpose of reciprocating linear motion with high speed, high precision, no vibration and impact.

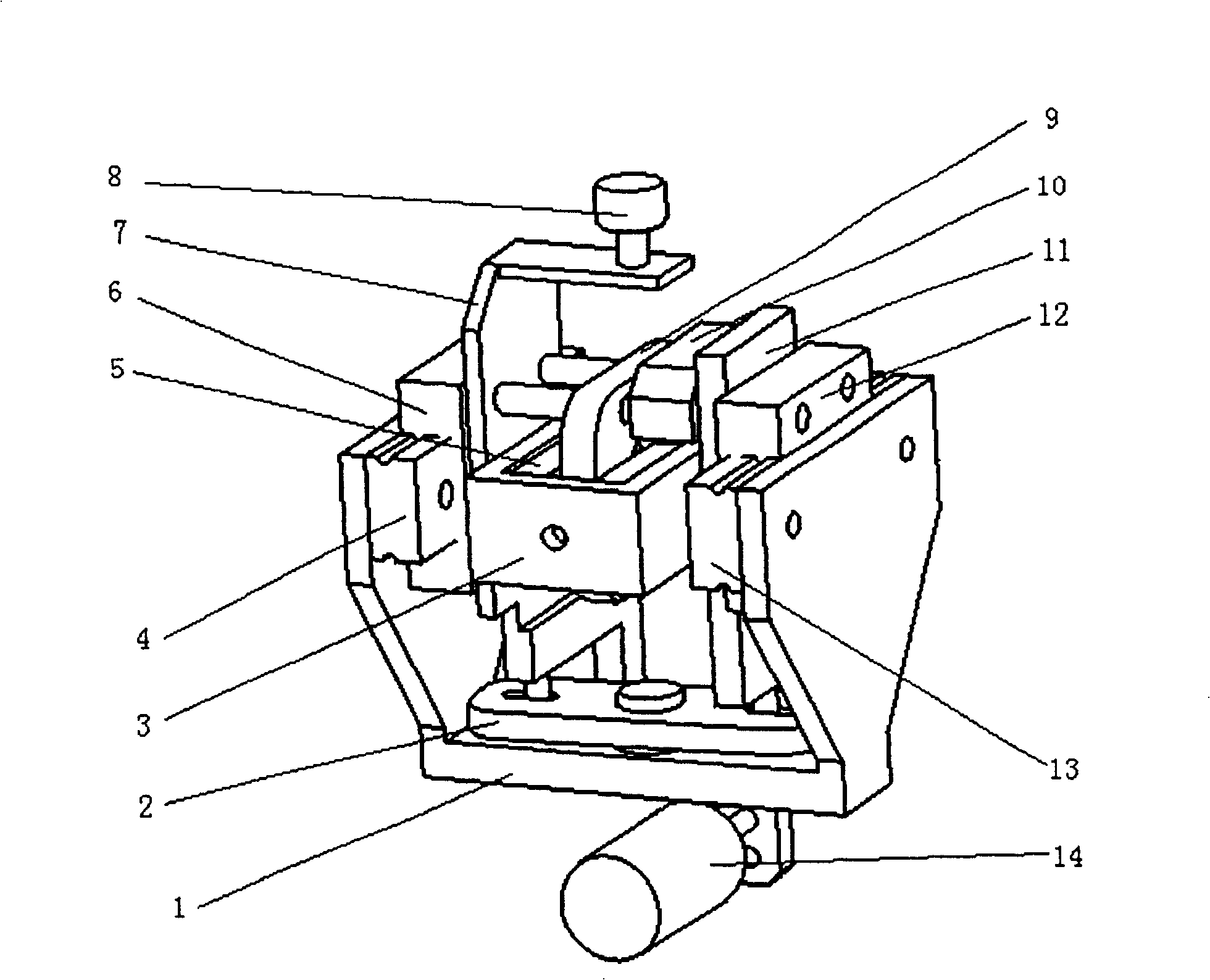

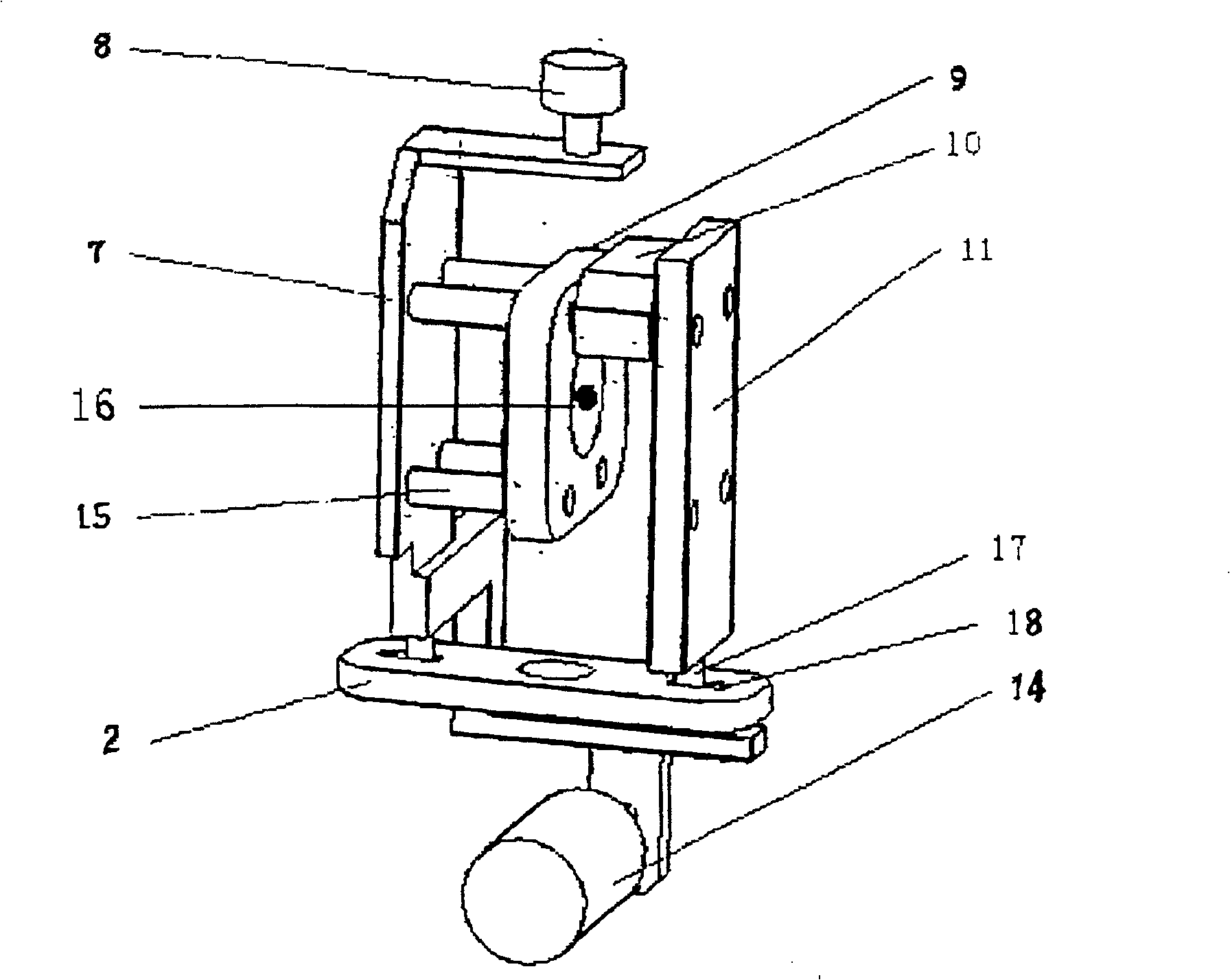

[0025] figure 1 Shown is the three-dimensional structural diagram of the small-scale non-vibration linear motion device of the present invention, which includes: a shell 1, a magnetic steel 5 that produces two parallel magnetic fields in opposite directions in the magnetic steel fixing frame 3, a rectangular coil 9, A mover fixed with the recta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com