Internal-flow dispersed-air floatation machine and its working method

An air flotation machine and air-dispersing technology, which is applied in the direction of flotation water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve problems such as poor effect, and achieve the problem of poor effect and high probability of combination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

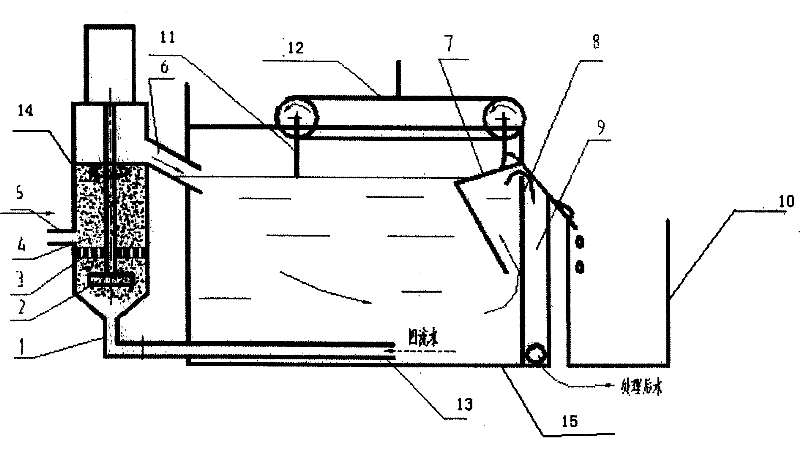

[0008] Embodiment: a kind of air flotation machine (see accompanying drawing 1) of internal flow scattered air, it is made of a circular air flotation force head 14 and air flotation tank 15, baffle plate 7, water outlet weir plate 8, slag scraping mechanism 12, backflow The sewage treatment device and the clean water storage device formed by the pipe 13 are characterized in that the circular air floating power head placed on the side wall of the air floating tank is composed of a circular gas producing wheel that generates tiny bubbles, a return water inlet, and a rectifying plate. , a mixing chamber, a water inlet and a water outlet. The circular gas production wheel that produces tiny bubbles is placed in the lower part of the rectangular air flotation tank. There is a return water inlet below the gas production wheel. There is a mixing chamber above the rectifying plate, and water inlets and water outlets on both sides of the circular air-floating head, and the circular air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com