A cemented well wall reinforcement agent and its preparation method

A technology of reinforcing agent and cementing agent is applied in the field of cemented well wall reinforcing agent and preparation to achieve the effect of eliminating scattered shedding phenomenon, significant fragmentation effect of broken objects, and eliminating collapse and falling blocks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

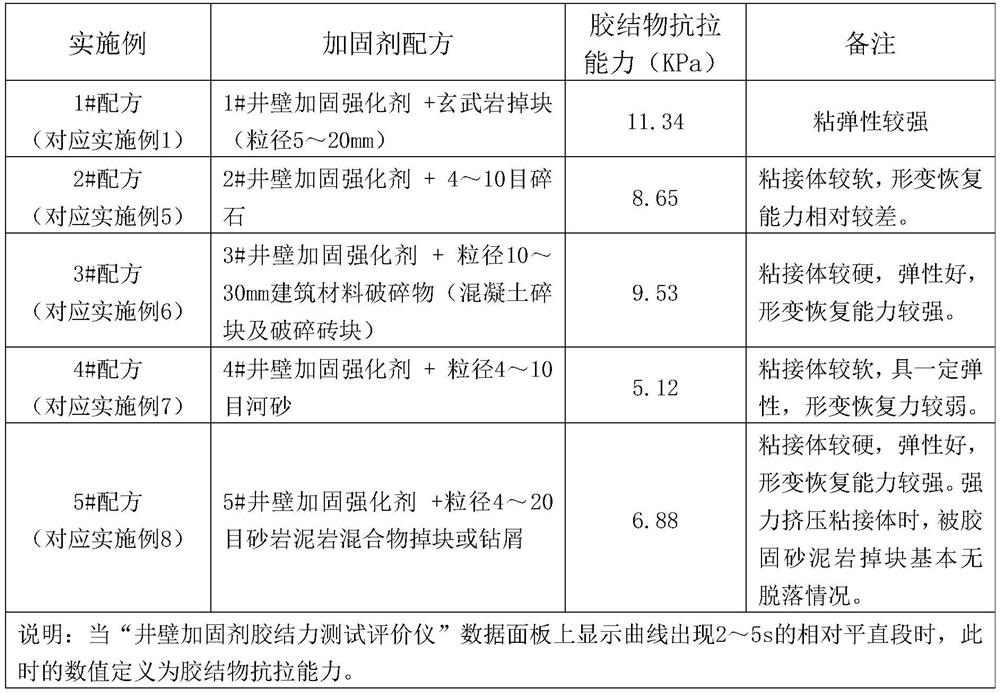

Embodiment 1

[0077] 1# formula cement and its preparation method:

[0078] Formula: 300 parts of rheology regulator (AGE), 1000 parts of main agent (E44), 500 parts of curing agent (dicyandiamide), and 50 parts of accelerator (thiourea).

[0079] Preparation method: weigh the required parts by weight of each component in proportion. Under stirring (speed 350-500rmp), slowly add the main agent of the cementing agent to the 200 parts of the rheology regulator, and stir until the main agent is completely dissolved to obtain component A; Add curing agent and accelerator to the conditioner, and stir until the curing agent and accelerator are completely dissolved to obtain component B; the above components A and component B are stored separately, and components A and B are mixed evenly to obtain Formulation 1# cement that cures in water.

Embodiment 2

[0081] 2# formula cement and its preparation method:

[0082] Formula: 350 parts of rheology modifier (AGE), 1000 parts of main agent (E44), 300 parts of curing agent (dicyandiamide), 30 parts of accelerator (thiourea).

[0083] Preparation method: weigh the required parts by weight of each component in proportion. Under stirring (speed 350-500rmp), slowly add the main agent of the cementing agent to the 280 parts of the rheology regulator, and stir until the main agent is completely dissolved to obtain component A; Add curing agent and accelerator to the conditioner, and stir until the curing agent and accelerator are completely dissolved to obtain component B; the above components A and component B are stored separately, and components A and B are mixed evenly to obtain 2# formulation cement that cures in water.

Embodiment 3

[0085] 3# Formula cement and its preparation method:

[0086] Formula: rheology regulator (HK-66) 200 parts, main agent (E51) 1000 parts, curing agent (phenol formal hexamethylenediamine) 100 parts, accelerator (2-methylimidazole-salicylate) 10 parts share.

[0087] Preparation method: weigh the required parts by weight of each component in proportion. Under stirring (rotating speed 350-500rmp), slowly add the main agent of the cementing agent to 120 parts of the rheology regulator, and stir until the main agent is completely dissolved to obtain component A; Add curing agent and accelerator to the conditioner, and stir until the curing agent and accelerator are completely dissolved to obtain component B; the above components A and component B are stored separately, and components A and B are mixed evenly to obtain 3# formulation cement that cures in water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com