Vehicle leather instrument board and weakening machining method thereof

A processing method and instrument panel technology, applied in chemical instruments and methods, vehicle parts, vehicle safety arrangements, etc., can solve the problems that cannot completely solve the problems of weakened lines, uneven alignment, and increased alignment processes, so as to ensure the appearance and the effect on perceived quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the vehicle leather instrument panel and its weakening processing method proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

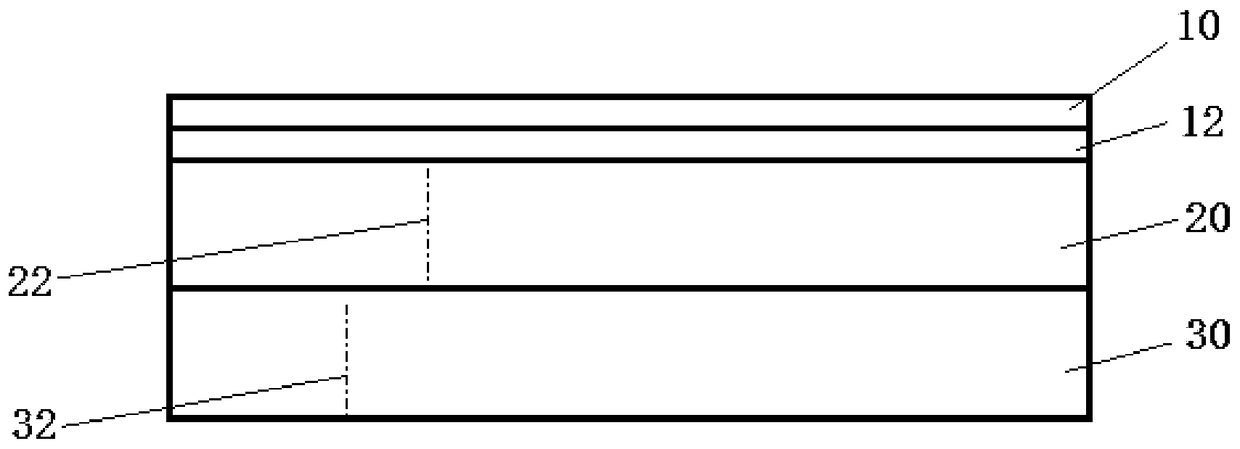

[0033] see figure 1 As shown, the vehicle leather instrument panel provided according to one embodiment of the present invention includes a skin layer, an intermediate layer 20 and a skeleton layer 30 arranged sequentially from top to bottom, wherein the skin layer includes a cortical layer 10 and a support layer 12 .

[0034] Further, the thickness of the cortical layer is 0.3mm-0.7mm, and the preferred solution adopted in one embodiment is 0.4mm-0.6mm. Its constituent material can be genuine leather or artificial leather, without limitation. The supporting layer has a thickness of 0.4 mm to 0.6 mm and is made of soft fabric material. The overall thickness of the epidermis is 1.0 mm to 1.2 mm.

[0035] According to the vehicle le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com