3D printer with door lock structure

A technology of 3D printer and door lock structure, applied in the direction of 3D object support structure, time lock, building lock, etc., can solve the problems of a large amount of ink dust, ink dust diffusion, environmental pollution, etc., to avoid diffusion to the outside of the box, The effect of maintaining air cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the above-mentioned features and effects of the present invention more clear and understandable, the following specific examples are given together with the accompanying drawings for detailed description as follows.

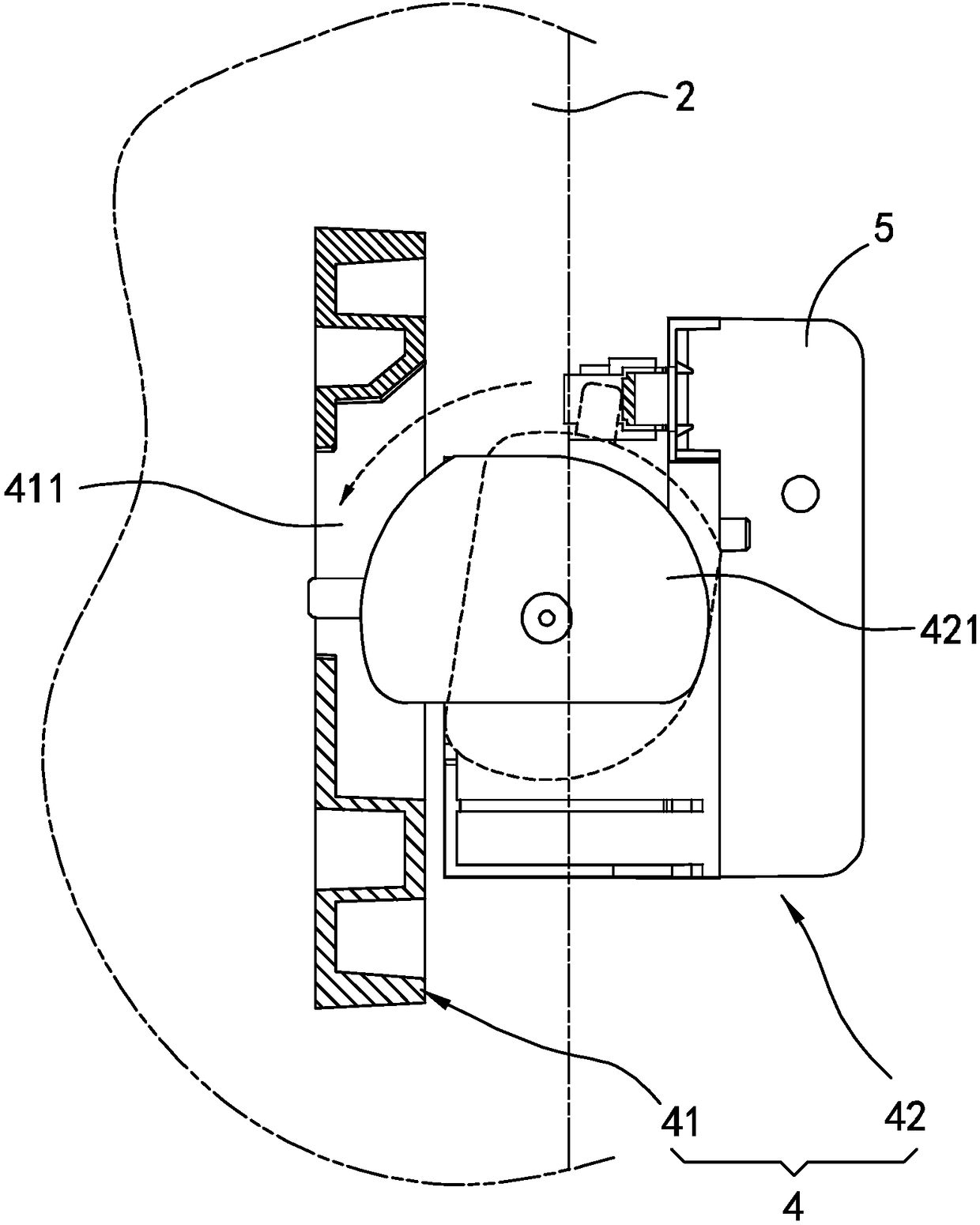

[0043] Please refer to Figure 1 to Figure 7 As shown, the present invention provides a 3D printer with a door lock structure. The 3D printer 10 mainly includes a box body 1, a door panel 2, a door lock structure 4, an actuator 5, a three-dimensional nozzle 61, a color Nozzle group 62 , a ventilation structure 7 and a controller 8 .

[0044] like figure 1 , Figure 4 As shown, the box body 1 has a cavity 11 inside and an opening 12 communicating with the cavity 11 , and the box body 1 has a stop piece 13 extending on one side of the opening 12 .

[0045] like Figure 1 to Figure 3 As shown, the door panel 2 is pivotally connected to the box body 1, the door panel 2 can be moved to the closed position of the closed opening 12 and the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com