Moving device for cooling machine modular installation

A mobile device and cooling machine technology, which is applied to workshop equipment, manufacturing tools, etc., can solve the problems of limited space and the inability to hoist large-scale installation machinery, and achieve the effects of simple structure, improved installation efficiency and quality, and flexible and accurate movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

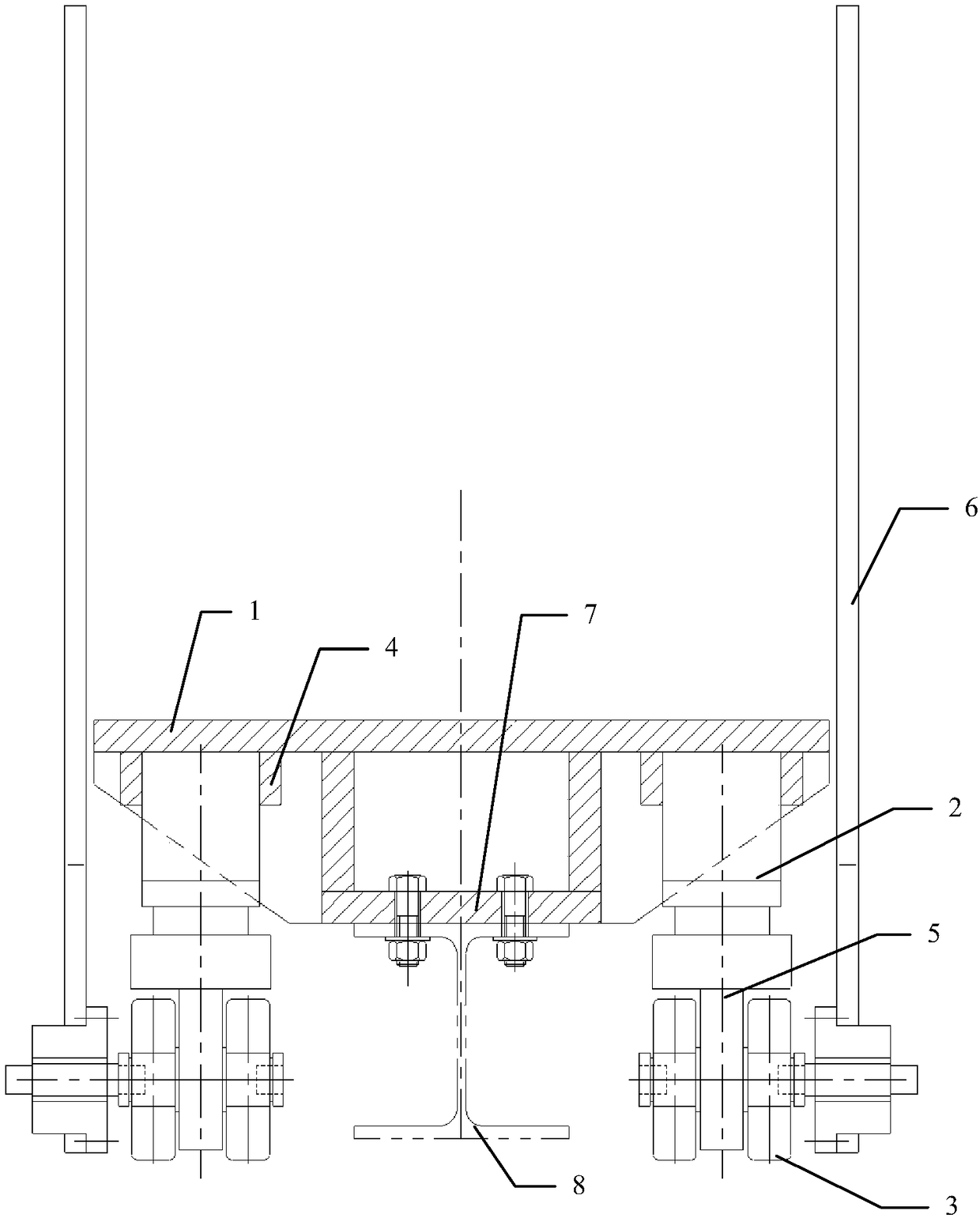

[0017] The preferred embodiment 1 of the present invention provides a mobile device for modular installation of a cooling machine, which includes a number of device bodies used in conjunction with each other (such as figure 1 As shown), the device body includes a jacking frame 1, a lifting mechanism 2 and a supporting roller 3, the top of the lifting mechanism 2 is connected with the jacking frame 1, and the bottom end is connected with the supporting roller 3. The side of the jacking frame 1 is also provided with a drive arm 6 connected to the roller shaft of the supporting roller 3 and capable of driving the roller 3 to rotate; Connecting rack 7.

[0018] In order to ensure that the force of the jacking frame 1 is symmetrical, the number of the lifting mechanism 2 and the supporting roller 3 is two sets, which are respectively symmetrically arranged on both sides of the bottom of the jacking frame 1 .

[0019] The lifting mechanism 2 is a jack.

[0020] The bottom of the j...

Embodiment 2

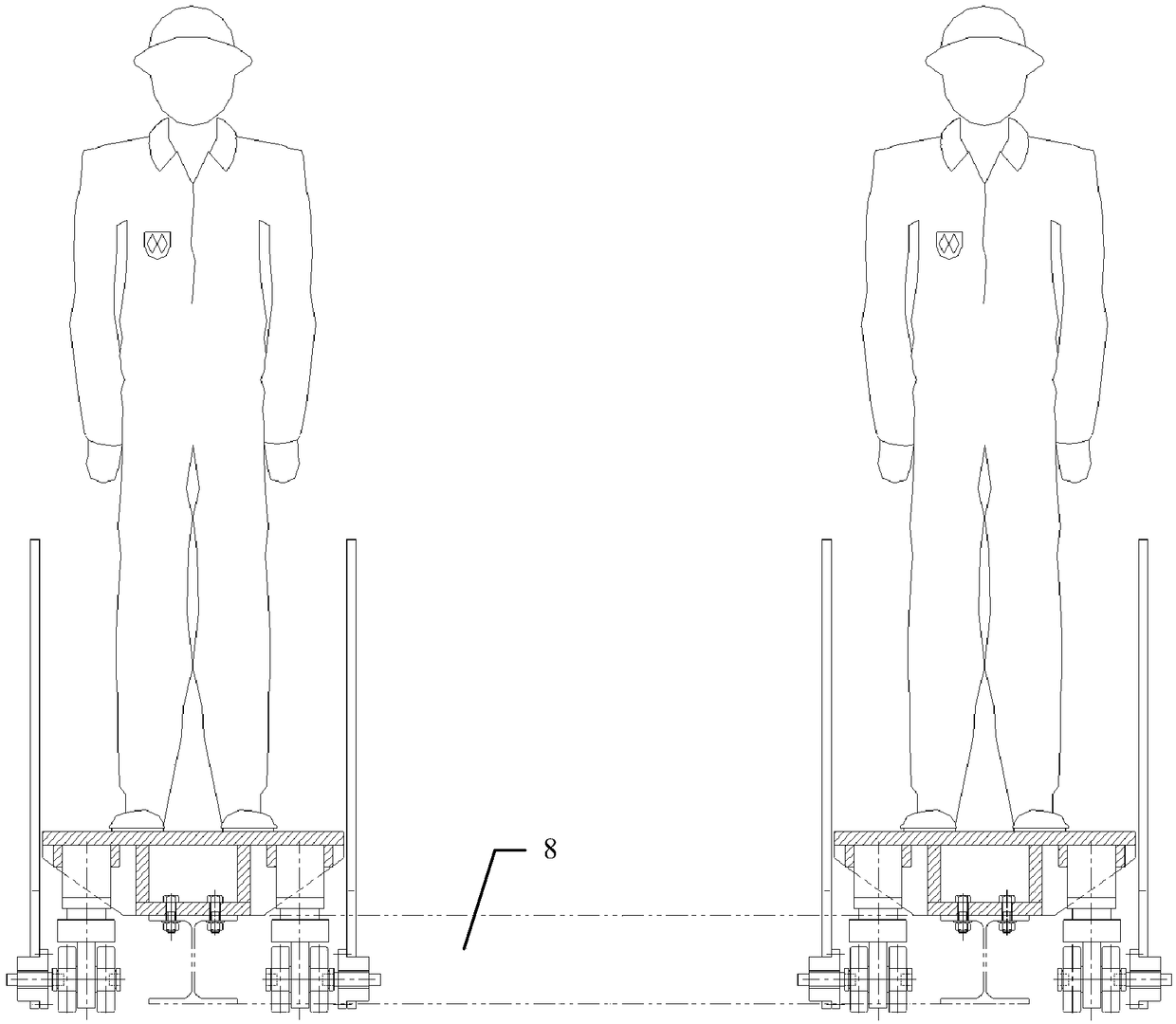

[0026] Preferred embodiment 2 of the present invention provides a mobile device for modular installation of cooling machines, including two (or four or more, can be selected according to actual conditions) cooperating with each other as described in embodiment 1 ontology. When using this mobile device, the connecting frame on the jacking frame 1 is connected to the bottom frame of the module by bolts, so as to realize the solid connection between the jacking frame and the bottom frame of the module. The jack cooperates with the sleeve 4 of the jacking frame 1, and is pushed between the support roller 3 and the jacking frame 1. Then the push rod of the jack 2 is extended, and after the support roller 3 touches the ground, the module bottom frame 8 is hoisted by the jacking frame 1 under the thrust of the jack. Then move each device body (the operator can stand on the jacking frame to operate the driving arms on both sides of the jacking frame at the same time), and lift the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com