A kind of preparation method of nickel nitride-nickel foam composite lithium metal negative electrode current collector

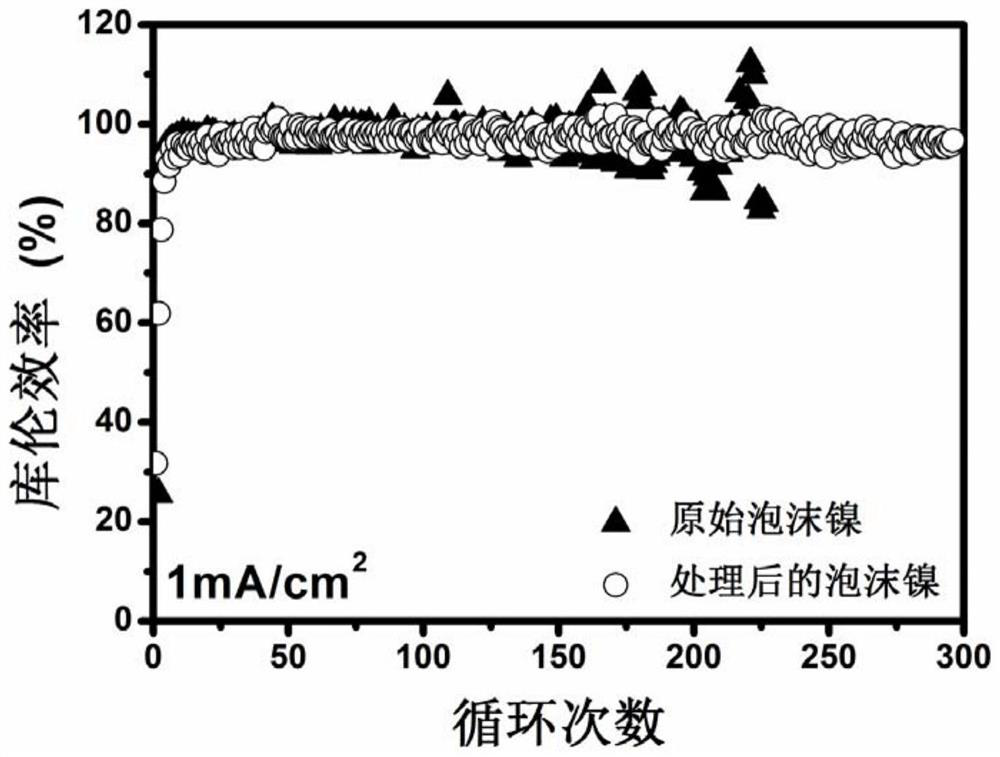

A metal negative electrode and nickel foam technology, applied in the direction of electrode carrier/current collector, battery electrode, structural parts, etc., can solve the problems of low theoretical capacity of graphite negative electrode, reduced battery Coulombic efficiency, reduced battery cycle life, etc., to reduce nucleation Effects of overpotential, inhibition of dendrite growth, and reduction of local current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

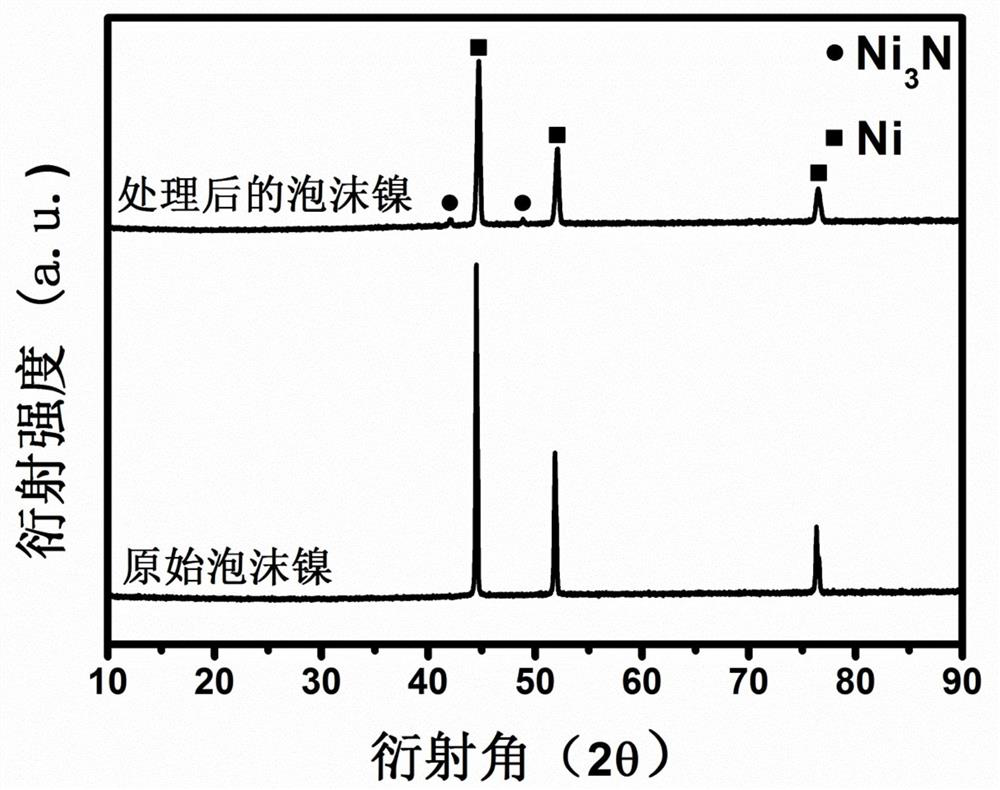

[0035] A preparation method of nickel nitride-foam nickel composite lithium metal negative electrode collector, comprising the following steps:

[0036] 1) Stamp nickel foam into a disc with a diameter of 12mm, ultrasonically clean it with acetone, 2mol / L hydrochloric acid, and ethanol for 5 minutes, and then dry it at 80°C for 120 minutes;

[0037] 2) The nickel foam after drying is placed in the discharge plasma reaction furnace, the reaction furnace is evacuated, and the reaction gas is passed into the reaction furnace with the ratio and flow rate of hydrogen: nitrogen = 75sccm: 75sccm, and the control of the reaction furnace The vacuum degree is 150Pa;

[0038] 3) Turn on the radio frequency power supply, control the voltage to 550V, and the duty cycle to 85%, so that the plasma is discharged, the ionized working gas is high-energy particles bombarding nickel foam, the reaction temperature is controlled to be 450 ° C, the reaction time is 120 minutes, and natural cooling i...

Embodiment 2

[0041] A preparation method of nickel nitride-foam nickel composite lithium metal negative electrode collector, comprising the following steps:

[0042] 1) Stamp the nickel foam into a disc with a diameter of 12mm, ultrasonically clean it with acetone, 5mol / L hydrochloric acid, and ethanol for 10 minutes, and then dry it at 120°C for 300 minutes;

[0043] 2) The nickel foam after drying is placed in the discharge plasma reaction furnace, the reaction furnace is evacuated, and the reaction gas is passed into the reaction furnace with the ratio and flow rate of nitrogen: hydrogen=10sccm: 90sccm, and the control of the reaction furnace The vacuum degree is 200Pa;

[0044] 3) Turn on the radio frequency power supply, control the voltage to 350V, and the duty cycle to 35%, so that the plasma is discharged, the ionized working gas is high-energy particles bombarding nickel foam, the reaction temperature is controlled to be 300°C, the reaction time is 120min, and natural cooling is p...

Embodiment 4

[0053] A preparation method of nickel nitride-foam nickel composite lithium metal negative electrode collector, comprising the following steps:

[0054] 1) Stamp nickel foam into a disc with a diameter of 12mm, ultrasonically clean it with acetone, 5mol / L hydrochloric acid, and ethanol for 30 minutes, and then dry it at 120°C for 300 minutes;

[0055] 2) the nickel foam after drying is placed in the discharge plasma reaction furnace, the reaction furnace is evacuated, and the reaction gas is passed into the reaction furnace with the flow of nitrogen=500sccm, and the vacuum degree of the control reaction furnace is 500Pa;

[0056] 3) Turn on the radio frequency power supply, control the voltage to 700V, and the duty cycle to 85%, so that the plasma is discharged, the ionized working gas is high-energy particles bombarding nickel foam, the reaction temperature is controlled to be 600°C, the reaction time is 600min, and natural cooling is obtained to obtain nitrogen Nickel-nickel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com