Real-time fluorescence detecting device of microreactor and operating method thereof

A technology of microreactor and real-time fluorescence, applied in fluorescence/phosphorescence, instruments, measuring devices, etc., can solve the problems of inability to detect multi-target molecules and detection system cannot achieve more channels, achieving high sensitivity and easy operation , the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

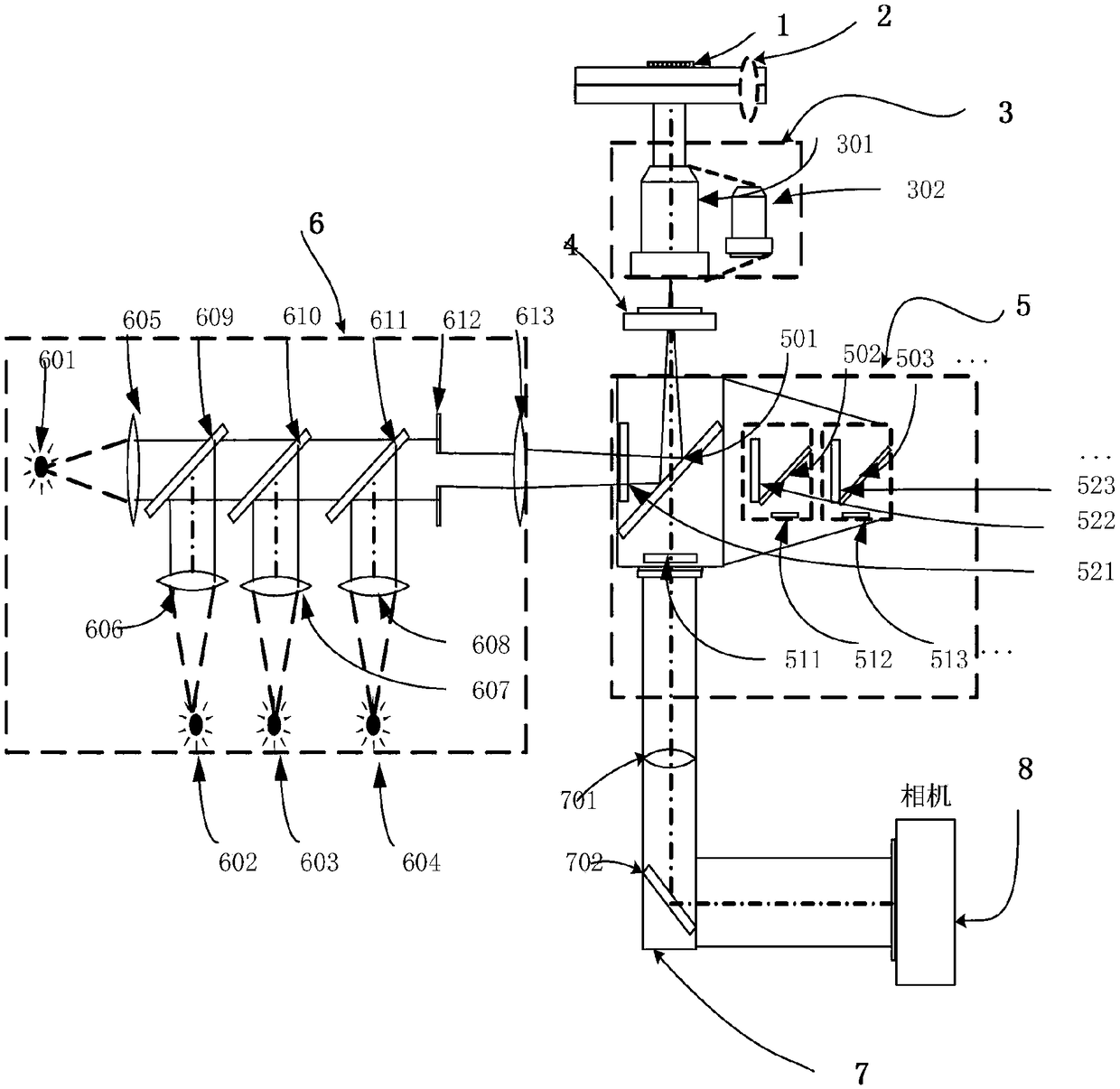

[0063] Such as figure 2 As shown, 601, 602, 603, 604 represent different lasers, 609, 610, 611, and 613 represent different first beam combiners, 612 represents the field diaphragm, and 605, 606, 607, and 608 represent different collimators. Lens, 301 and 302 represent different objective lenses. 501, 502, and 503 indicate different dichroic mirrors, 511, 512, and 513 indicate different filters in the imaging light path, and 521, 522, and 523 indicate different filters in the illumination light path.

[0064] The excitation light source of the light path diagram of the four-color fluorescence system is composed of four groups, each group of excitation light sources includes a laser and a collimating lens, and the laser and the collimating lens are matched. The light source chooses 405nm, 532nm, 638nm and 802nm wavelength fiber laser light source. 601 is an 802nm fiber laser, 602 is a 638nm fiber laser, 603 is a 532nm fiber laser, and 604 is a 405nm fiber laser.

[0065] Accordin...

Embodiment 2

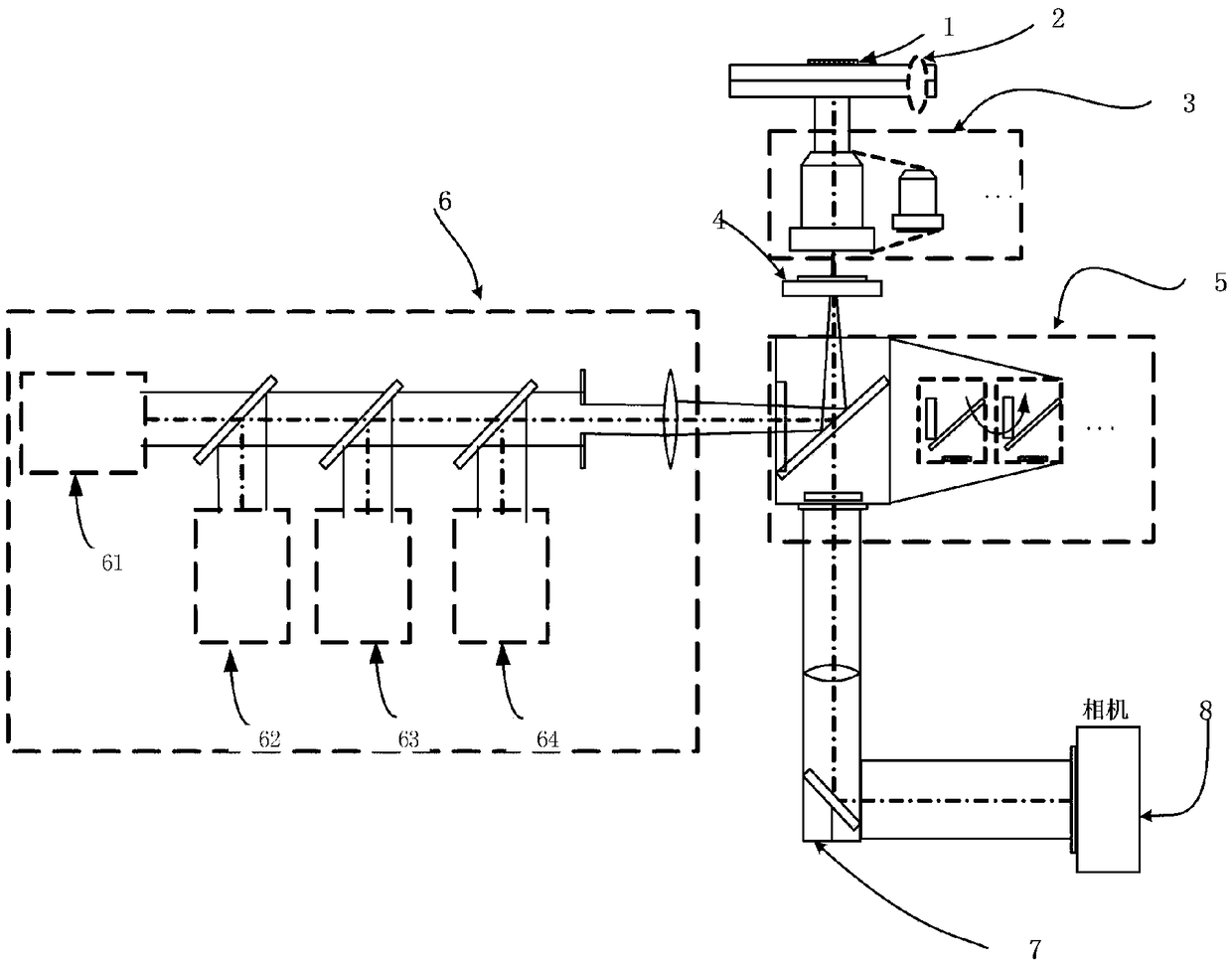

[0081] image 3 61 is the red band, 62 is the yellow band, 63 is the green-blue band, and 64 is the purple band. Figure 4 6101, 6102, 6103, 6104, 6201, 6202, 6203, 6204, 6301, 6302, 6303, 6304, 6401, 6402, 6403, 6404 indicate different lasers, 6105, 6106, 6107, 6108, 6205, 6206, 6207 , 6208, 6305, 6306, 6307, 6308, 6405, 6406, 6407, 6408 indicate different collimating lenses, 6109, 6110, 6111, 6209, 6210, 6211, 6309, 6310, 6311, 6409, 6410, 6411 indicate different The second beam combiner.

[0082] Such as image 3 with Figure 4 As shown, there are four groups of excitation light sources in the light path diagram of the sixteen-color fluorescence system, each group of excitation light sources includes four groups of second excitation light sources, and each group of second excitation light sources includes a laser, a collimator lens, and several second beam combiners. The lasers are matched with the collimating lens, and the second beam combiner is used to combine the beams of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com