Method for processing underground continuous wall collapse holes

A technology of underground diaphragm wall and treatment method, which is applied in the direction of excavation, sheet pile wall, foundation structure test, etc., to achieve the effect of ensuring smooth progress, improving construction quality, and simple construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

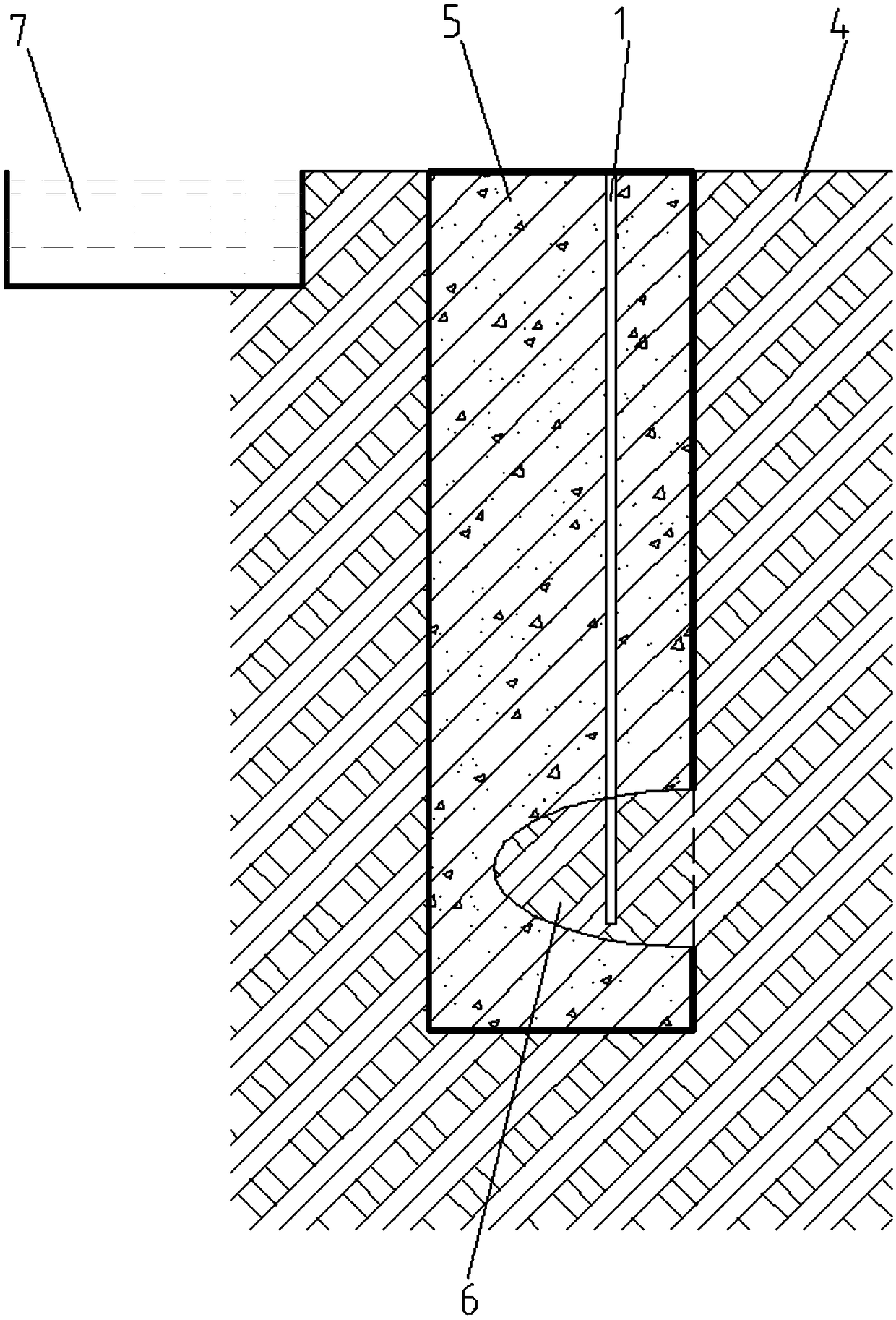

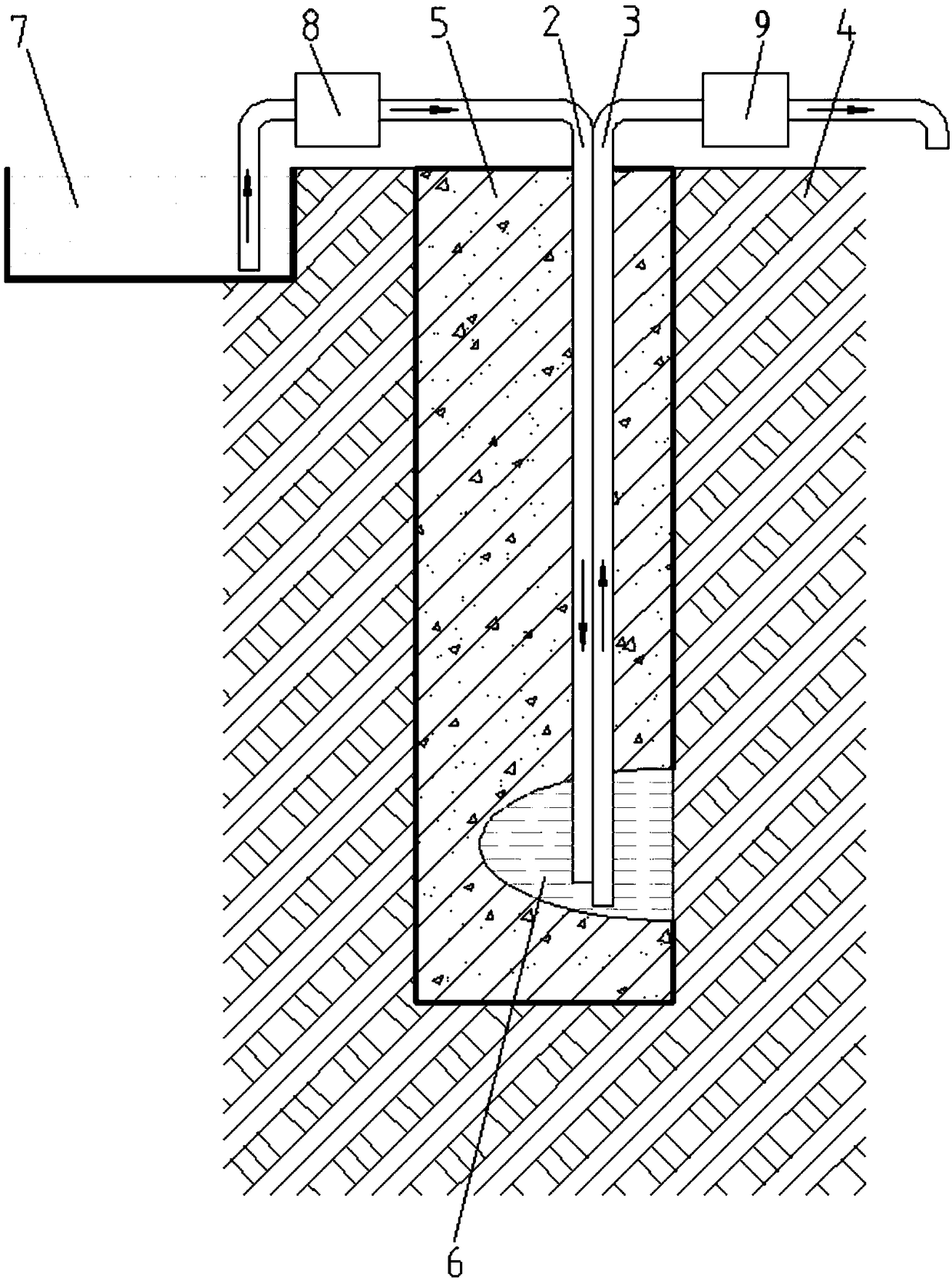

[0027] Such as figure 1 As shown, a specific embodiment of a method for processing the collapse of an underground continuous wall, a section of in-line groove section is taken as an example, the design groove section length is 6m, the groove section depth is 5m, the wall thickness is 800mm, and the ground connecting wall is 5 (Underground continuous wall) The concrete strength grade is C40, the longitudinal reinforcement is 18mm diameter HRB400 grade steel, and the impermeability grade is p6. The soil layer 4 around the ground wall is mainly soft cohesive soil, and the groundwater level is 7m deep.

[0028] In the first step, after the construction of the ground connecting wall 5 is completed (the concrete did not reach the design strength during the curing period), the loose and weak soil around the ground connecting wall collapsed during the trough formation process, and the inspectors found and initially detected the approximate location of the collapsed hole .

[0029] The sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com