High fatigue strength non-magnetic steel and preparation method thereof

A technology of fatigue strength and non-magnetic steel, which is applied in the field of high fatigue strength, low magnetic permeability, high manganese non-magnetic steel and its preparation, can solve the problems of affecting the service life of devices and low fatigue strength of non-magnetic steel, and achieve easy operation , improved fatigue strength, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

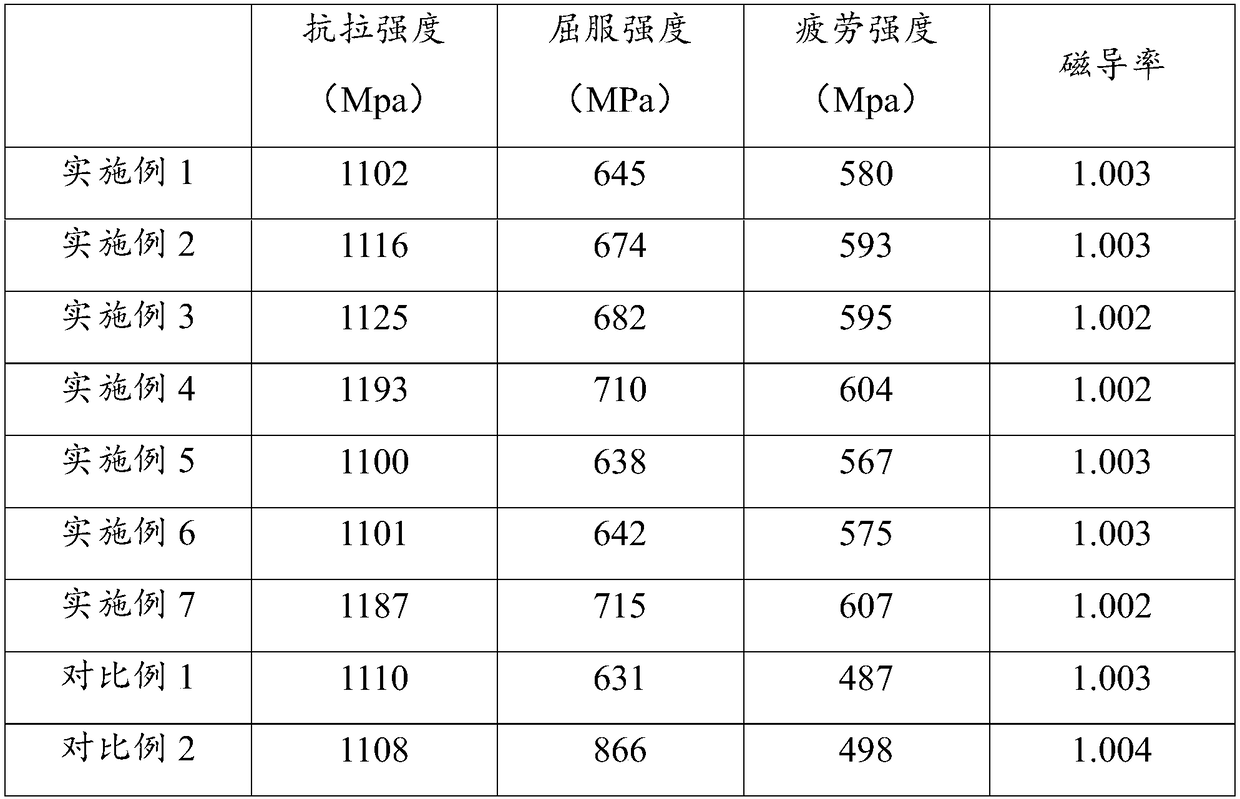

Examples

Embodiment 1

[0032] This embodiment provides a high-fatigue strength non-magnetic steel whose mass percentage composition is: C: 0.4%, Si: 0.4%, Mn: 17.5%, Cr: 4%, V: 1.5%, La: 0.1%, P : 0.03%, S: 0.02%, the balance is Fe.

[0033] The preparation method of the above non-magnetic steel includes the following steps:

[0034] Vacuum melting: according to the ratio of each element in the high-strength non-magnetic steel, the raw materials are mixed and put into the vacuum melting furnace, and the vacuum is pumped to 10 -3 Next, fill with argon gas with a purity of 99.99%, and arc smelt into ingots;

[0035] Vacuum casting: After smelting, the ingot is polished and the surface oxide layer is put into a vacuum electromagnetic induction furnace, and the vacuum degree in the furnace cavity is pumped to 10 -4 Below Pa, fill with argon gas with a purity of 99.99%, melt the ingot by high-frequency induction heating, and cast it into a billet;

[0036] Hot-rolling process: After the slab is kept at 1200℃ for...

Embodiment 2

[0039] This embodiment provides a high-fatigue strength non-magnetic steel whose mass percentage composition is: C: 0.4%, Si: 0.4%, Mn: 17.5%, Cr: 4%, V: 1.5%, La: 0.1%, P : 0.04%, S: 0.01%, the balance is Fe.

[0040] The preparation method of the above non-magnetic steel includes the following steps:

[0041] Vacuum melting: according to the ratio of the elements in the high-strength non-magnetic steel, the raw materials are mixed and put into the vacuum melting furnace, and the vacuum is pumped to 10 -3 Next, fill with argon gas with a purity of 99.99%, and arc smelt into ingots;

[0042] Vacuum casting: the ingot after smelting is polished and the surface oxide layer is put into a vacuum electromagnetic induction furnace, and the vacuum degree in the furnace cavity is pumped to 10 -4 Below Pa, fill with argon with a purity of 99.99%, melt the ingot by high-frequency induction heating, and cast it into a billet;

[0043] Hot rolling process: After the cast slab is kept at 1200°C fo...

Embodiment 3

[0047] This embodiment provides a high-fatigue strength non-magnetic steel whose mass percentage composition is: C: 0.48%, Si: 0.4%, Mn: 18.5%, Cr: 4.5%, V: 1.3%, La: 0.15%, P : 0.02%, S: 0.02%, the balance is Fe.

[0048] The preparation method of the above non-magnetic steel includes the following steps:

[0049] Vacuum melting: according to the ratio of the elements in the high-strength non-magnetic steel, the raw materials are mixed and put into the vacuum melting furnace, and the vacuum is pumped to 10 -3 Below, it is filled with argon gas with a purity of 99.99% and arc-smelted into ingots;

[0050] Vacuum casting: the ingot after smelting is polished and the surface oxide layer is put into a vacuum electromagnetic induction furnace, and the vacuum degree in the furnace cavity is pumped to 10 -4 Below Pa, fill with argon gas with a purity of 99.99%, melt the ingot by high-frequency induction heating, and cast it into a billet;

[0051] Hot rolling process: After the cast slab is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Fatigue limit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com