Feeding and pretreatment system for raw materials of methane project

A pretreatment and raw material technology, which is applied in the field of biogas engineering, can solve problems such as poor site environment, failure to meet the design requirements of the raw material pretreatment system, and difficulty in metering and transportation, so as to reduce labor costs and energy consumption, and the pretreatment effect is obvious. The effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the drawings.

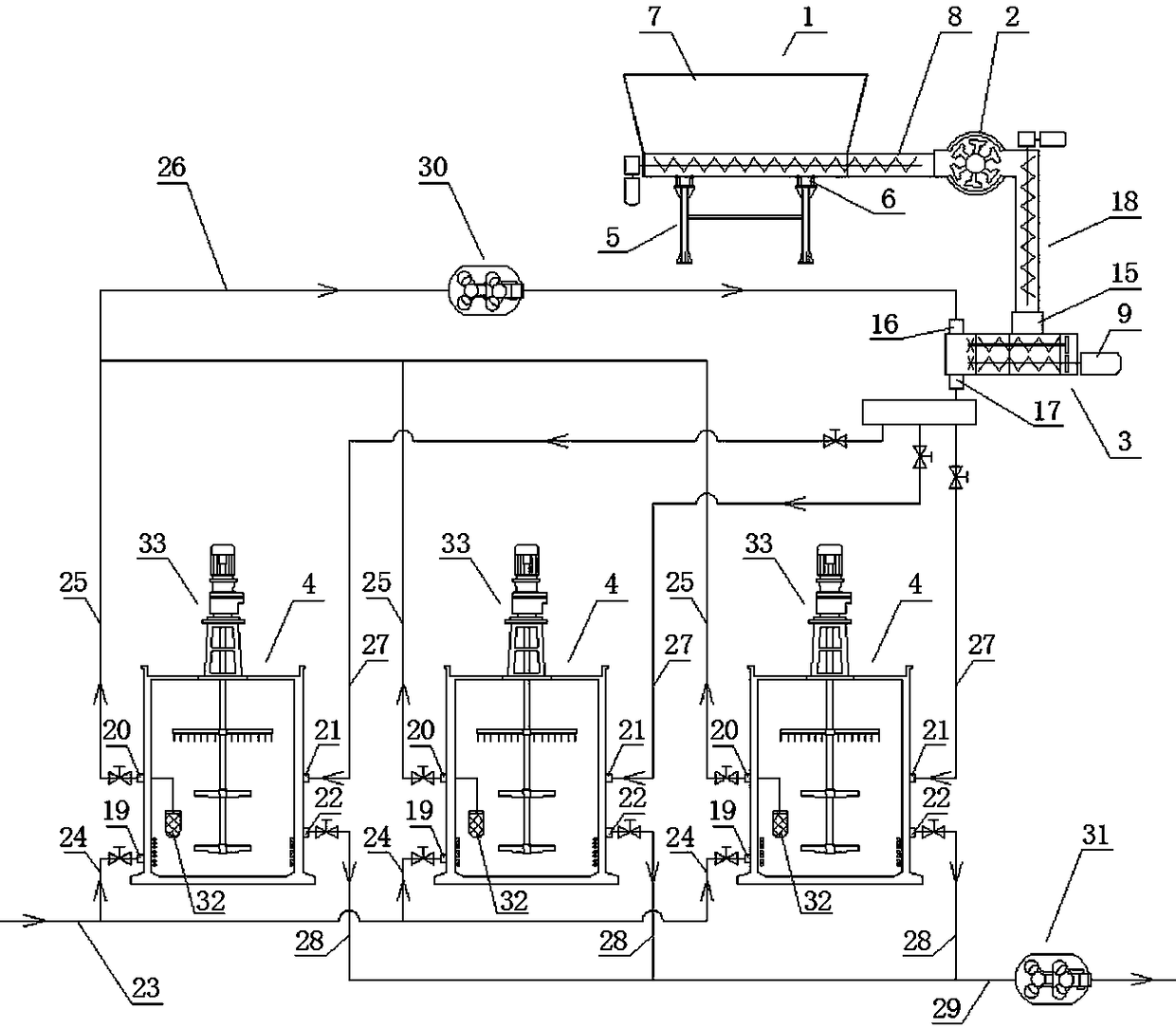

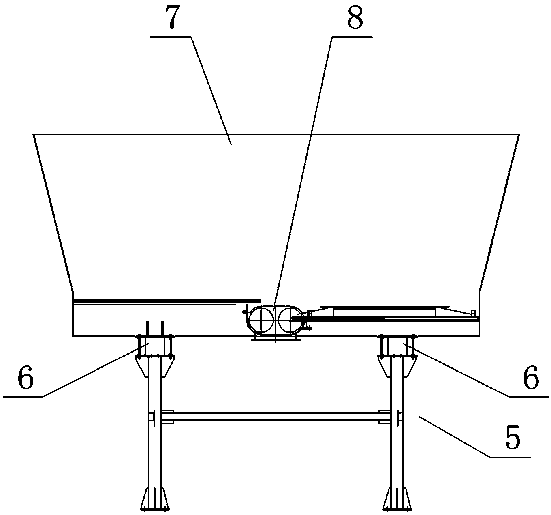

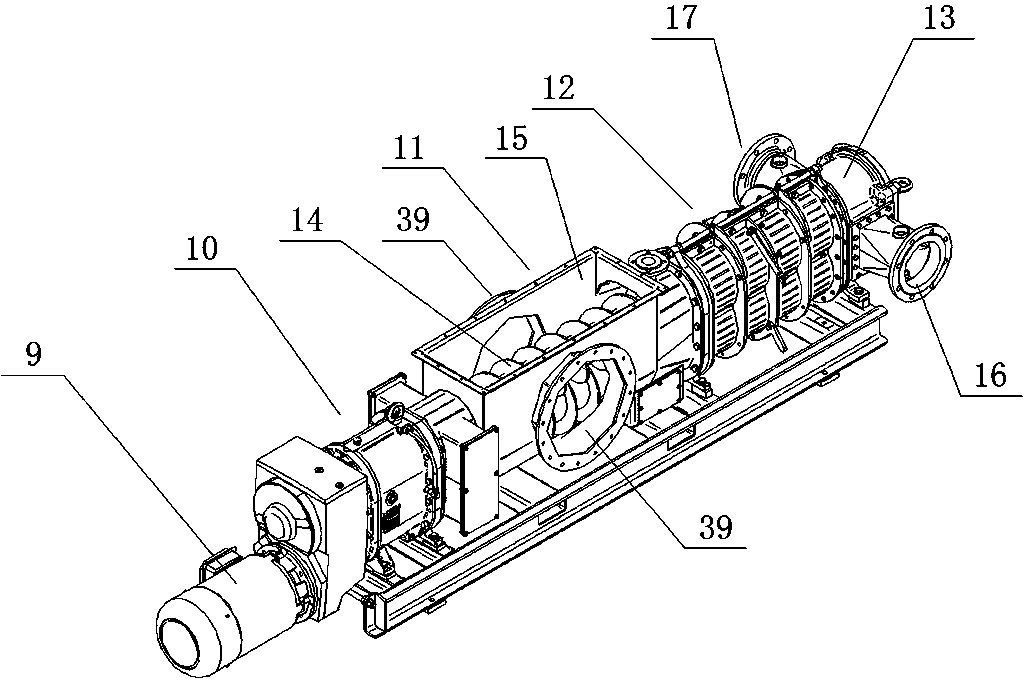

[0024] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a feed and pretreatment system for biogas engineering raw materials includes a weighing receiving bin 1, a crusher 2, a mixing conveyor 3, and three pretreatment tanks 4; the weighing receiving bin 1 Including a base 5, above the base 5 is a silo body 7 supported by a load cell 6. At the bottom of the silo body 7 is a screw unloader 8 for conveying raw materials to the crusher 2; the mixing conveyor 3 includes a motor 9, The gear box 10, the feeding chamber 11, the extrusion crushing chamber 12 and the mixing chamber 13 are provided with a twin screw 14 driven by a motor 9 and a gear box 10 inside the feeding chamber 11 and the extrusion crushing chamber 12. The feeding chamber 11 is provided with There is an upper feed port 15 and two side feed ports 39. The mixing chamber 13 is provided with a liquid inlet 16 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com