Preparation method of water-soluble acrylic resin for reflection film

A technology of water-soluble acrylic and reflective film, which is applied in the direction of reflection/signal paint, coating, etc., and can solve problems such as easy to burst bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

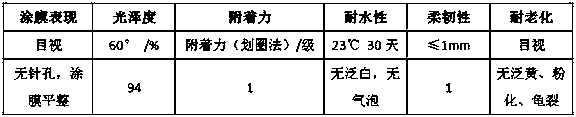

Embodiment 1

[0043] A method for preparing a reflective film with a water-soluble acrylic resin, comprising the following raw materials in parts by weight:

[0044] 4 parts methyl methacrylate,

[0045] 10 parts of ethyl acrylate,

[0046] 3 parts lauryl methacrylate,

[0047] 1 part of hydroxyethyl methacrylate,

[0048] 3 parts acrylic,

[0049] 15 parts of 1-ethoxy-2 propanol,

[0050] 3 parts of dimethylethanolamine,

[0051] 40 parts of deionized water,

[0052] Benzoyl peroxide 0.2 parts,

[0053] The preparation steps are as follows:

[0054] (1) At room temperature, weigh 30% of the total weight of methyl methacrylate, 30% of the total weight of ethyl acrylate, 30% of the total weight of lauryl methacrylate, and 30% of the total weight of hydroxyethyl methacrylate. %, 30% of the total weight of acrylic acid, 45% of the total weight of 1-ethoxyl-2 propanol, 15% of the total weight of benzoyl peroxide, and they are mixed and prepared to form mixed solution A;

[0055] (2) Pu...

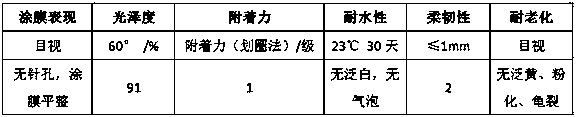

Embodiment 2

[0063] A method for preparing a reflective film with a water-soluble acrylic resin, comprising the following raw materials in parts by weight:

[0064] 10 parts of methyl methacrylate,

[0065] 17 parts of ethyl acrylate,

[0066] Lauryl methacrylate 7 parts,

[0067] 4 parts of hydroxyethyl methacrylate,

[0068] Acrylic acid 5 parts,

[0069] 22 parts of 1-ethoxy-2 propanol,

[0070] 5 parts of dimethylethanolamine,

[0071] 50 parts of deionized water,

[0072] Benzoyl peroxide 0.4 parts,

[0073] The preparation steps are as follows:

[0074] (1) At room temperature, weigh 15% of the total weight of methyl methacrylate, 20% of the total weight of ethyl acrylate, 20% of the total weight of lauryl methacrylate, and 25% of the total weight of hydroxyethyl methacrylate. %, 25% of the total weight of acrylic acid, 45% of the total weight of 1-ethoxyl-2 propanol, 15% of the total weight of benzoyl peroxide, and they are mixed and prepared to form mixed solution A;

[00...

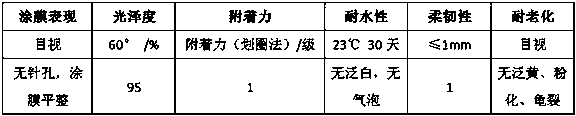

Embodiment 3

[0083] A method for preparing a reflective film with a water-soluble acrylic resin, comprising the following raw materials in parts by weight:

[0084] 7 parts of methyl methacrylate,

[0085] 13.5 parts of ethyl acrylate,

[0086] Lauryl methacrylate 5 parts,

[0087] 2.5 parts of hydroxyethyl methacrylate,

[0088] 4 parts acrylic,

[0089] 18.5 parts of 1-ethoxy-2 propanol,

[0090] 4 parts of dimethylethanolamine,

[0091] 45 parts of deionized water,

[0092] Benzoyl peroxide 0.3 part,

[0093] The preparation steps are as follows:

[0094] (1) At room temperature, weigh 22.5% of the total weight of methyl methacrylate, 25% of the total weight of ethyl acrylate, 25% of the total weight of lauryl methacrylate, and 27.5% of the total weight of hydroxyethyl methacrylate. %, 27.5% of the total weight of acrylic acid, 50% of the total weight of 1-ethoxy-2 propanol, and 25% of the total weight of benzoyl peroxide, and they are mixed and prepared to form mixed solution A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com