Sponge iron filtering oxygen removal device

A technology of sponge iron and deaerator, which is applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of uneconomical operation and inability to achieve the deaeration effect by the deaeration method, and achieve stable and reliable deaeration effect, simple construction, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

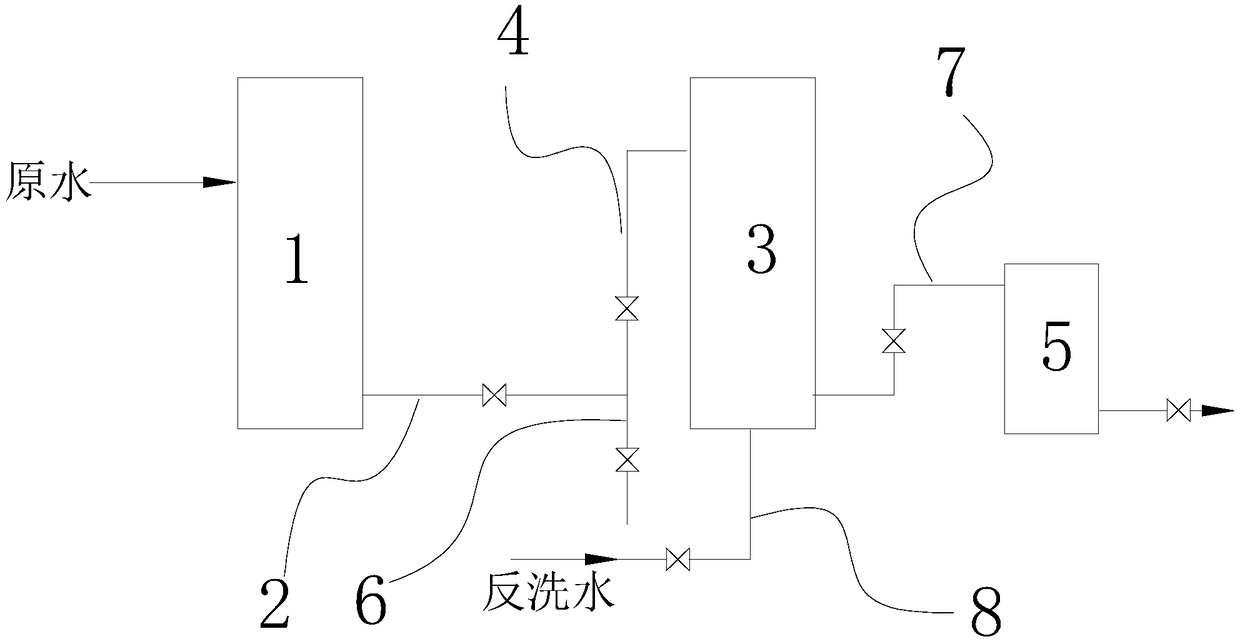

[0017] see figure 1 , a sponge iron filter oxygen removal device of the present invention is characterized in that: it comprises a water softener, a deaerator, and a deaerator water tank, and the output end of the water softener 1 is connected to the soft water inlet pipe 4 of the deaerator 3 by a pipeline 2 , the outlet pipe 7 of the deaerator 3 is connected to the inlet of the deaeration water tank 5, and the outlet pipe of the deaeration water tank 5 is connected to the boiler, and the bottom of the deaerator 3 is provided with a backwash water inlet pipe 8; the pipeline 2, soft water inlet Pipe 4, the outlet pipe of the deaerator 7, the backwash water inlet pipe 8, and the outlet pipe of the deaeration water tank are respectively equipped with solenoid valves, and the outer end of the solenoid valve on the outlet pipe of the deaeration water tank is also provided with a manual valve ; The solenoid valves are respectively connected to the controller; the bottom of the deaer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com