A method for placing circular plates for building construction

A construction and circular technology, which is applied in the direction of containers, packaging, and external accessories to prevent mechanical damage. It can solve the problems of inconvenient access to the lower circular plate, damage and rupture of the lower circular plate, and tilting of the circular plate. Achieve the effect of stable and firm overall structure, humanized design, and easy disassembly and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

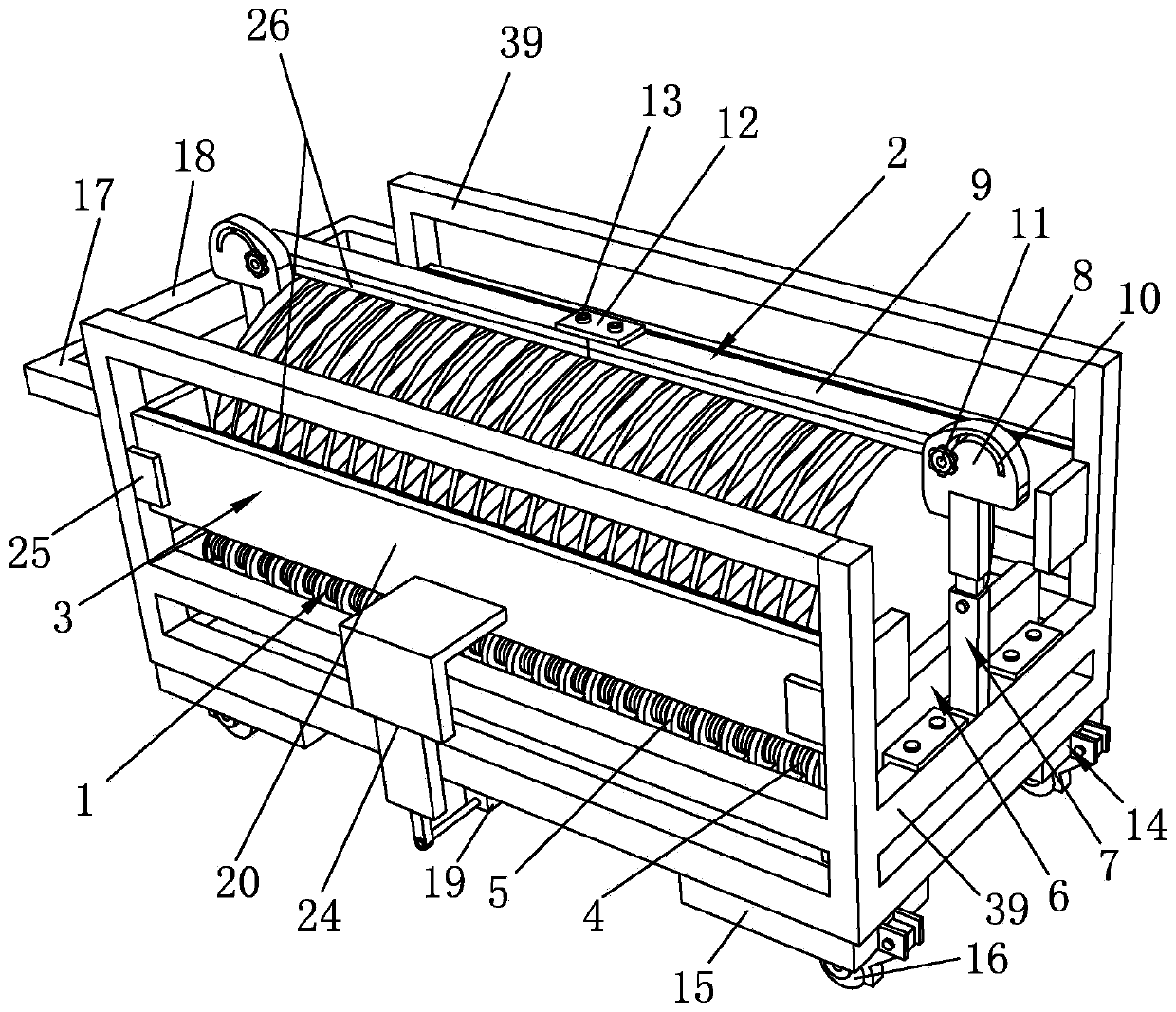

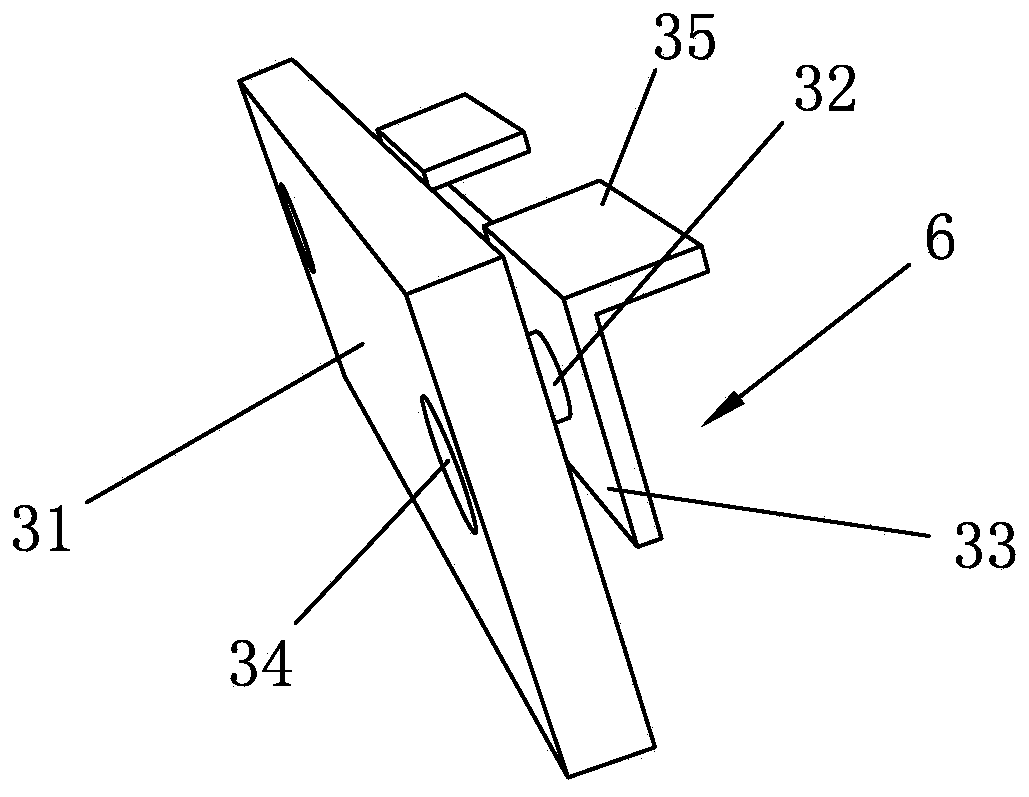

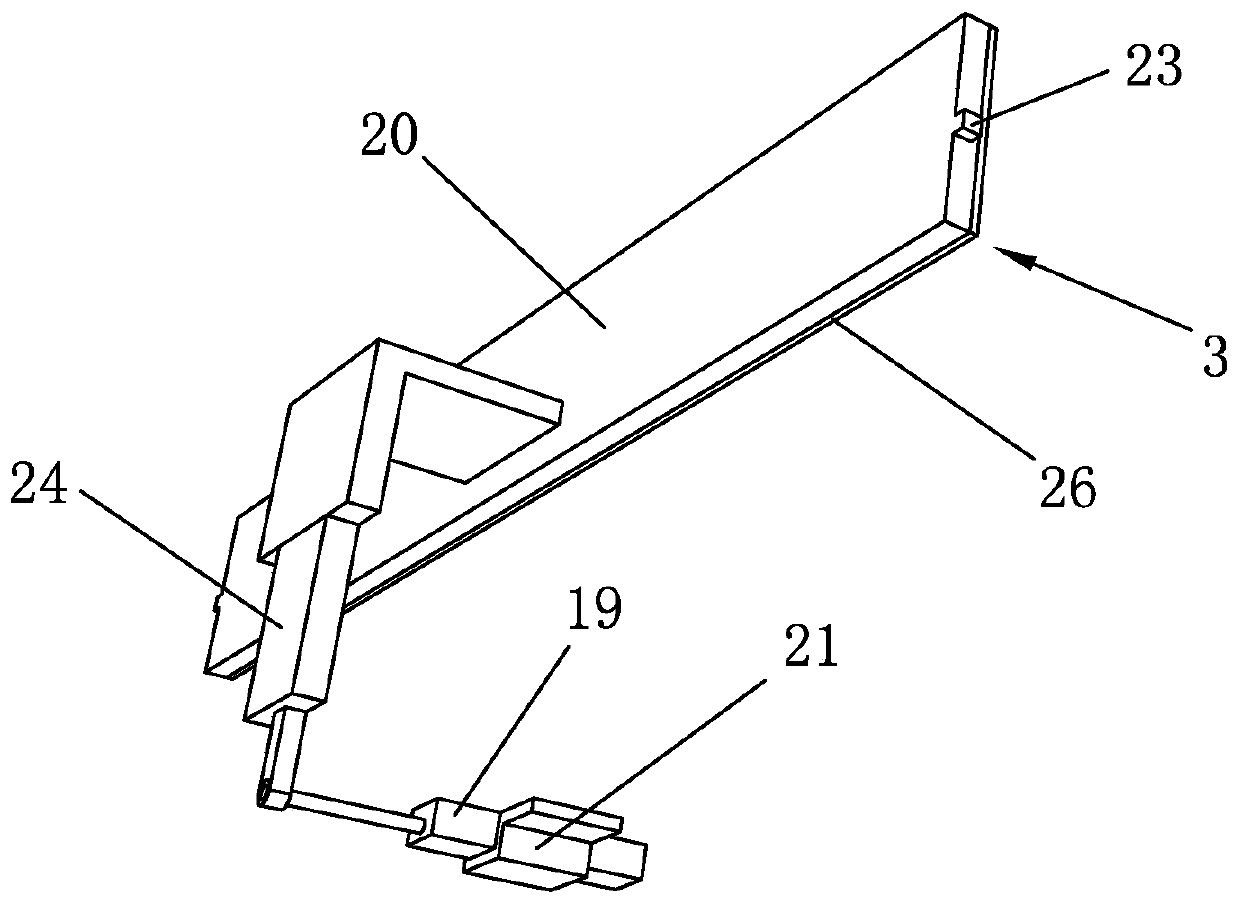

[0043] Such as Figure 1 to Figure 9 As shown, it is a placement frame for a circular plate used in building construction of the present invention, including a support body 39, and a mobile assembly 14 is arranged on the four corners of the bottom surface of the support body 39, and the mobile assembly 14 includes a shock absorber 15 and a mobile roller 16 , the mobile roller 16 is arranged on the shock absorber 15, the shock absorber 15 is screwed to the bottom surface of the support body 39, the rear end of the support body 39 is provided with a pull handle 17, and the pull handle 17 is provided with a protective cover 18, and the moving assembly 14 It can facilitate the movement of the support body 39, thereby moving the entire placement frame to the circular plate to be placed, which is convenient for the subsequent hoisting machine to hoist the circular plate into the placement frame. The design of the shock absorber 15 can facilitate the movement of the rollers The disas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com