Lower aeration type ceramic photocuring forming machine

A light-curing and molding machine technology, applied in the field of 3D printing, can solve the problems of increasing the cost of use, shortening the normal life of the projector, affecting the mechanical properties of ceramic products, etc., to ensure the effect of ensuring normal life and life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

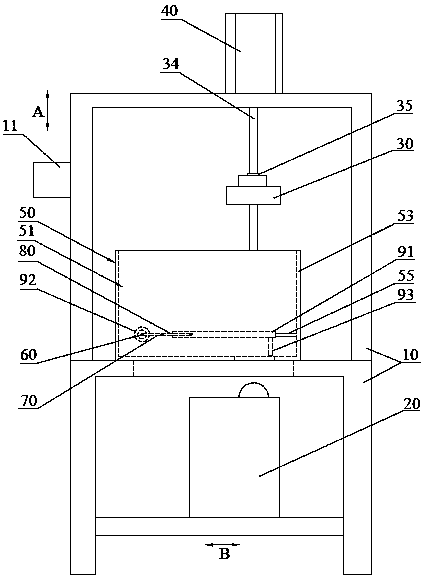

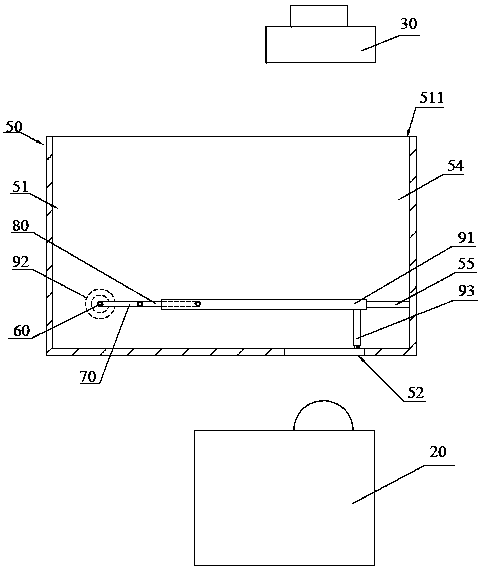

[0031] Such as Figure 1 to Figure 4As shown, the under-exposure ceramic light-curing molding machine of the present invention includes a frame 10, a projector 20, a controller 11, a printing platform 30, a lifting motor 40, a trough 50, a rotating shaft 60, a crank 70, a connecting rod 80, and a slide plate 91 and a driver 92 for driving the rotating shaft 60 to rotate and electrically connected with the controller 11 . The material trough 50 is installed at the frame 10, and the material trough 50 is supported and fixed by the frame 10; the material trough 50 has a cavity 511 arranged upwards and is used for containing the material cavity 51 of the light-curing liquid, so that the printing platform 30 is downward Move into the material chamber 51 through the cavity mouth 511, or move upwards through the cavity mouth 511 and move away from the material cavity 51; the bottom of the material tank 50 has a light-transmitting area 52 to allow the light generated by the projector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com