Special fixture capable of preventing clamping deformation for special-shaped support seat

A special fixture and support seat technology, applied in the field of tooling fixtures, can solve the problems of easy clamping and deformation of the outer surface of the circular boss, and achieve the effects of light weight, preventing product deformation, and ensuring processing accuracy requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

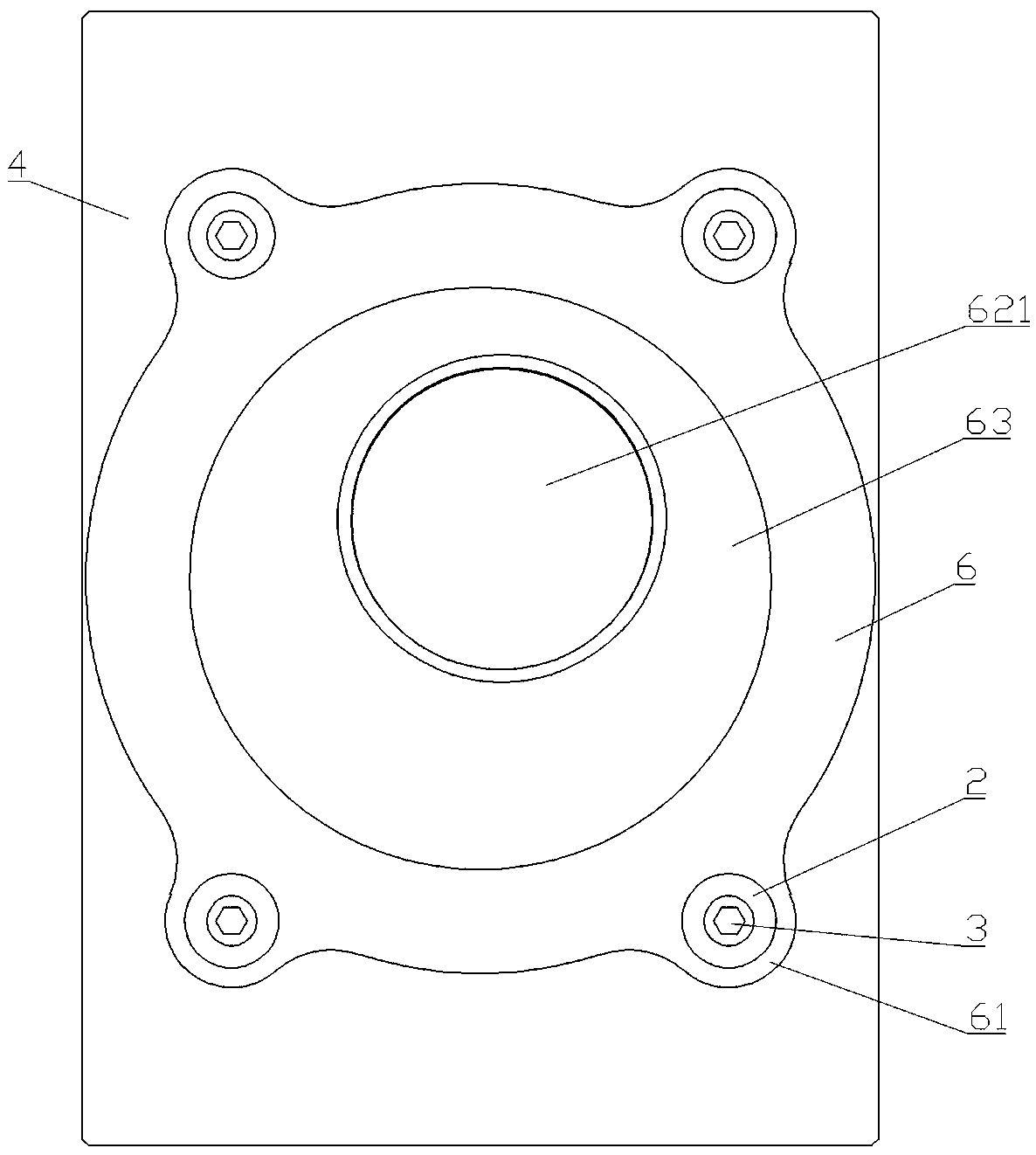

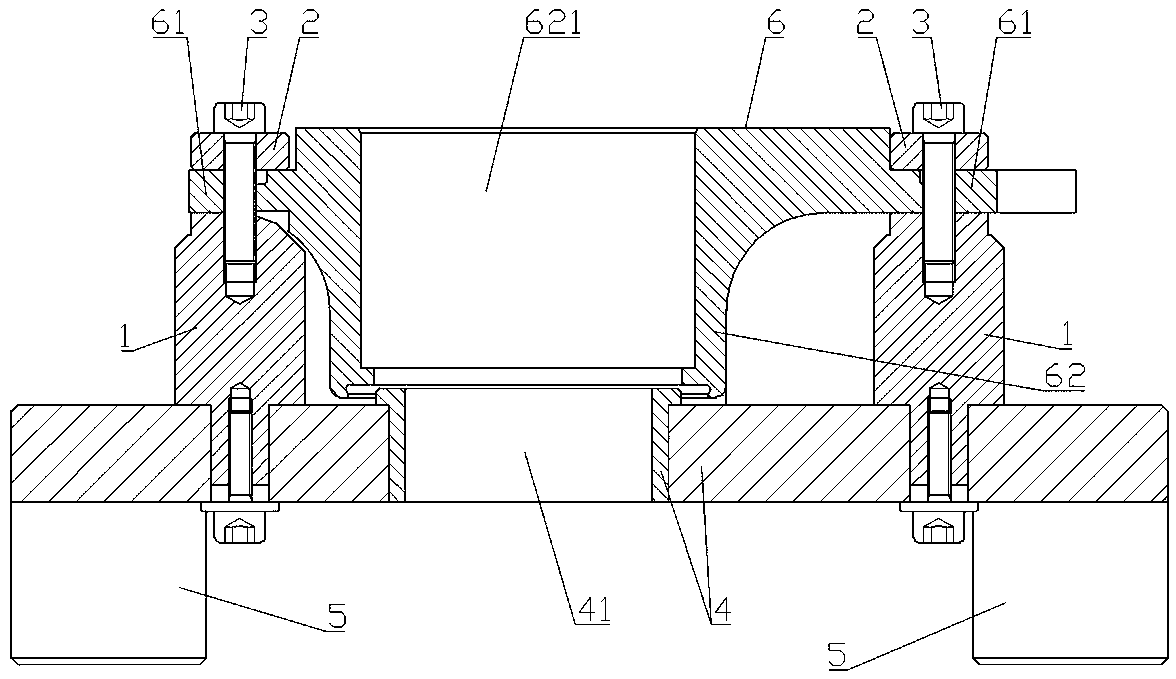

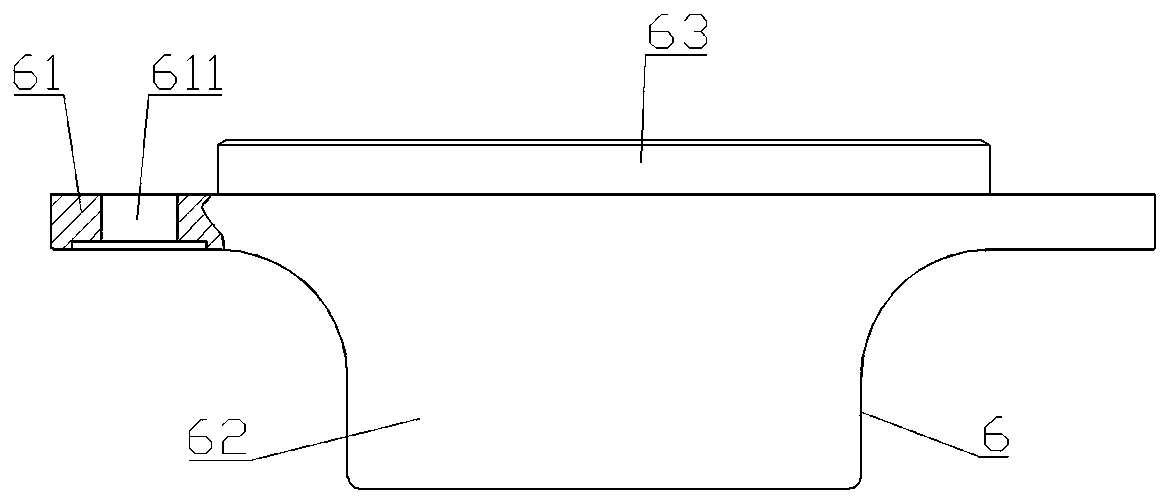

[0019] Such as Figure 1-2 As shown, the special clamp for special-shaped support seat that can prevent clamping deformation includes positioning column 1, pressing plate 2, pressing bolt 3, positioning plate 4 and supporting column 5.

[0020] There are four positioning columns 1, which are respectively supported on the lower ends of the four lugs 61 of the body 6, and the contours of the upper ends of the four lugs 61 on the lower surface of the body 6 match the contours of the lugs 61 on the lower surface of the body. The pressing plate 2 is arranged on the area of the ear plate 61 on the upper surface of the main body 6, and a hole for the pressing bolt 3 to pass is arranged on it. The pressing bolt 3 passes through the pressing plate 2, the lug plate 61 and the positioning column 1 in sequence to securely connect the three as a whole. The upper end surface of the positioning plate 4 is fixedly connected to the lower end of the positioning column 1 and is in contact wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com