Ultrathin air filtering screen

An air filter, ultra-thin technology, applied in the direction of filtration and separation, membrane filters, chemical instruments and methods, etc., can solve the problems of insufficient dust holding capacity of air purification equipment, insufficient area of high-efficiency filter, and affecting the effect of air purification. Achieve the effect of increasing dust holding capacity, improving filtering effect, and simple and effective structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with examples and specific implementation methods.

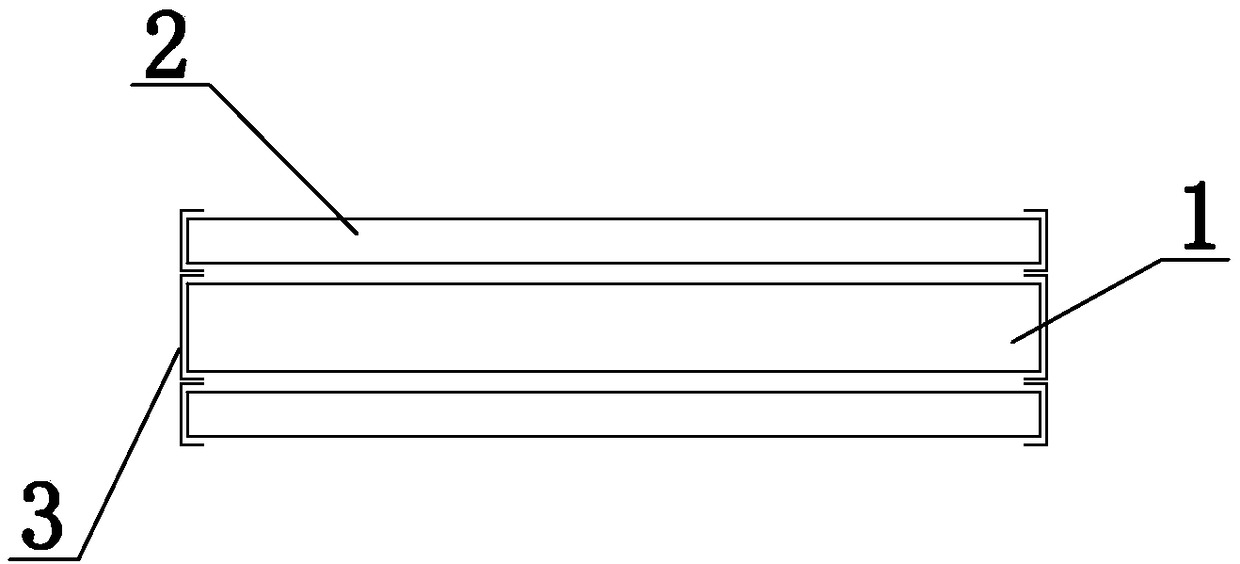

[0012] Such as figure 1 As shown, an ultra-thin air filter has an overall thickness of 3 to 9mm, and its structure includes a filter cotton layer 1, a metal mesh layer 2 and a paper frame 3, wherein the metal mesh layer 2 is arranged on the top surface of the filter cotton layer 1 And on the bottom surface, the four sides of the filter cotton layer 1 and the metal mesh layer 2 are connected and fixed by a paper frame 3 .

[0013] The filter cotton layer 1 is filter cotton of G3-F8 filter grade.

[0014] The four sides of the filter cotton layer 1 and the metal mesh layer 2 are respectively wrapped by independent paper frames 3 and superimposed on each other and connected and fixed by glue.

[0015] The above is only the preferred embodiment of the present invention, it should be pointed out that for those skilled in the art, without depar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com