Self-cleaning grill and method of use

A barbecue grill and self-cleaning technology, applied in applications, household stoves, heating methods, etc., can solve problems such as shortening the service life of fans and environmental pollution, and achieve the effects of improving use safety, reducing pollution, and reducing the amount of oil juice.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

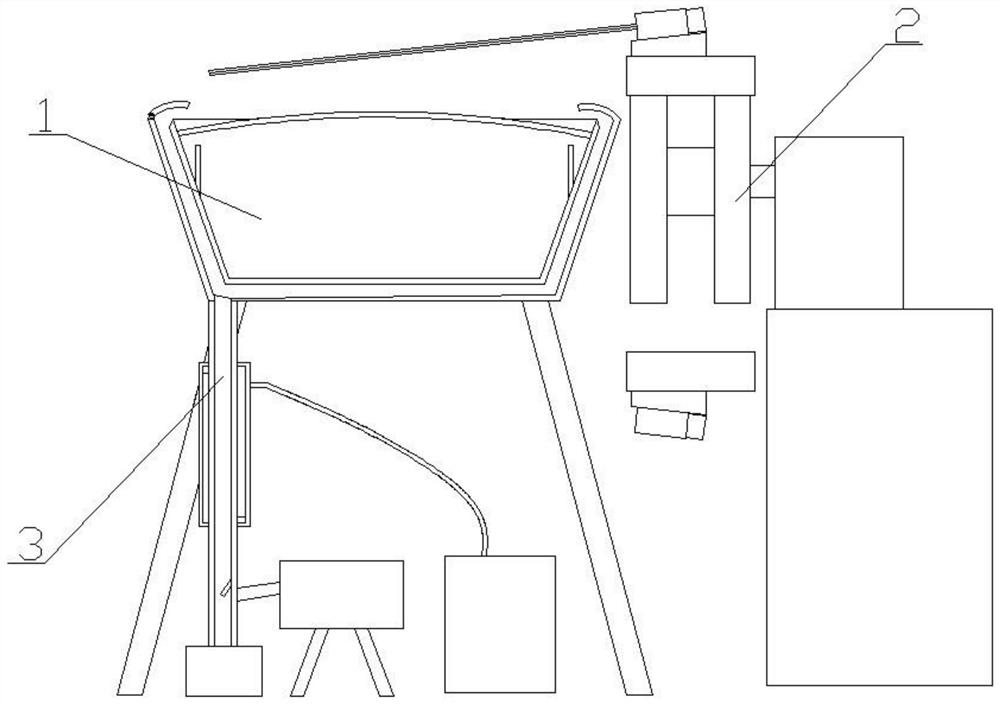

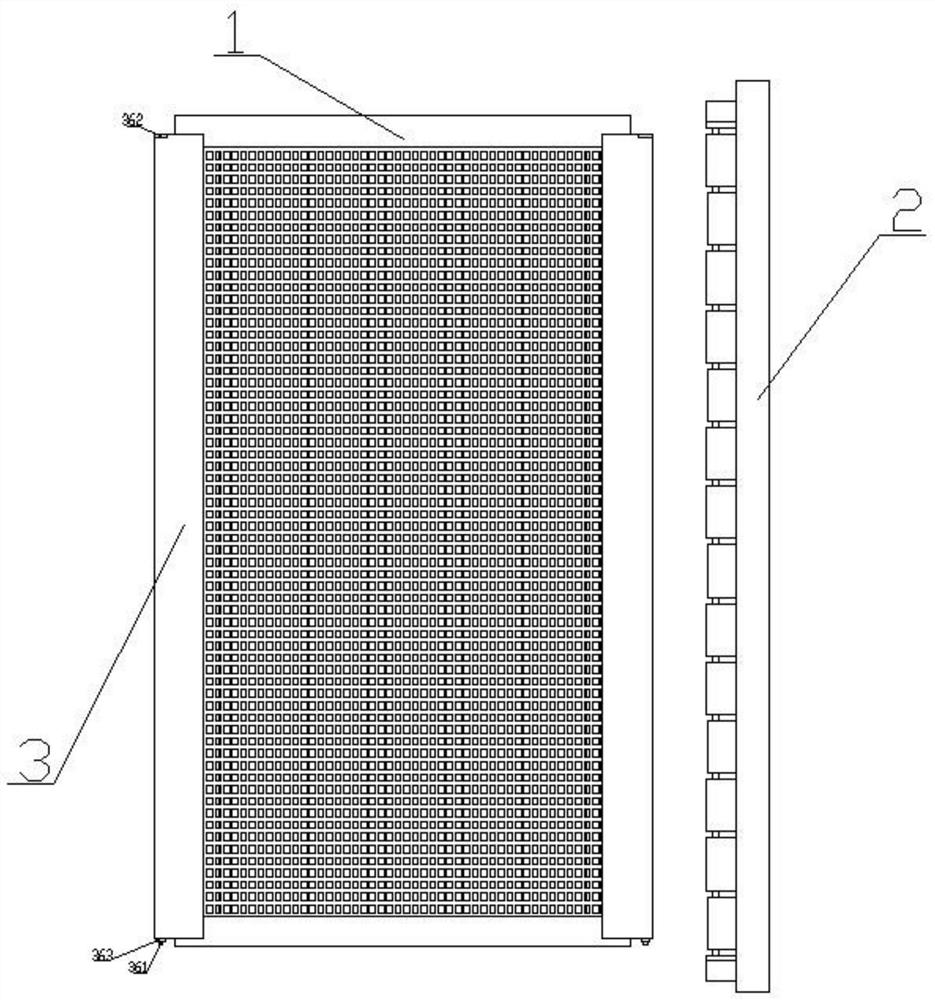

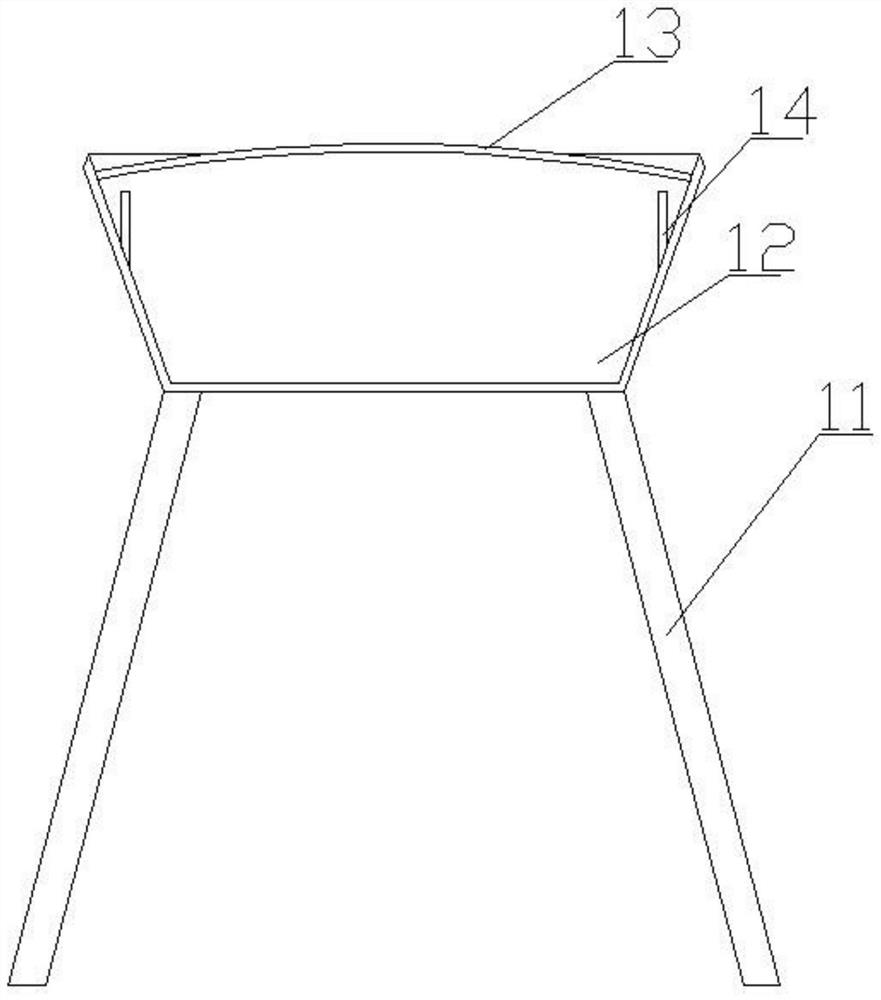

[0038] like figure 1 , figure 2 as shown, figure 1 It is a front view of the structure of the self-cleaning grill of the present invention; figure 2 It is a top view of the structure of the self-cleaning grill of the present invention; the self-cleaning grill of the present invention includes a grill 1, a grill mechanism 2 and a filter mechanism 3; the grill mechanism 2 and the filter mechanism 3 are both arranged on the On the grate 1, the grilling ingredients are fixed on the grilling mechanism 2; the grate 1 includes a bracket 11 and a heating part 12, the bracket 11 is used to fix the heating part 12, and the grilling mechanism 2 The grilled food is arranged on the heating part 12 to realize the heating and grilling treatment of the grilled food by the heating part 12 . The heating part 12 can be set as a heat collection tank for placing charcoal fire, and the barbecue mechanism 2 can place fixed barbecue ingredients on the heat collection tank for heating and grillin...

Embodiment 2

[0043] like Figure 4 as shown, Figure 4It is a structural view of the barbecue mechanism; the barbecue mechanism 2 includes a rolling frame 21 and a fixed group 22, several fixed groups 22 are fixed on the rolling frame 21, and the barbecue food is fixed on the fixed group 22 The rolling frame 21 drives the fixed group 22 to move, and by controlling the moving speed of the rolling frame 21, the grilling time of the grilled ingredients is controlled, so as to achieve a better grilling effect on the grilled ingredients.

[0044] The rolling frame 21 includes a plurality of rolling blocks 23 that are movably connected with each other and a brake wheel 24 that can drive the rolling blocks 23 to move. The rolling blocks 23 are connected to each other to form an endless rolling belt. The braking wheels 24 and the The rolling belt is connected by transmission, and the brake wheel 24 can drive the rolling belt to move, so as to realize the movement of the barbecue food on the heati...

Embodiment 3

[0059] Embodiment three carries out further improvement on the basis of embodiment two, as Figure 8 as shown, Figure 8 It is a structural view of the third embodiment of the fixing group; the improvement is that the fixing group 22 also includes an elastic part, the elastic part includes a straight rod 227 and a spring 228, the bottom plate 231 is provided with a through hole, and the One end of the straight rod 227 is provided with a limit block, and the size of the limit block is larger than the size of the through hole, so that the end of the straight rod 227 provided with the limit block is fixed on the bottom of the bottom plate 231. The other end of the straight rod 227 is fixedly connected to the bottom of the support 221; the spring 228 is sleeved on the straight rod 227, and the spring 228 is located between the support 221 and the bottom plate 231, The spring 228 provides an elastic repulsion force to the support 221 and the bottom plate 231 , so as to ensure that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com