Buried composite seepage pipe

A composite infiltration and buried technology, applied in watering devices, horticulture, botanical equipment and methods, etc., can solve the problems that the water seepage cannot be completely upward, affect the use effect, time-consuming and labor-intensive, etc., to overcome plant root blockage, The effect of high production efficiency and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

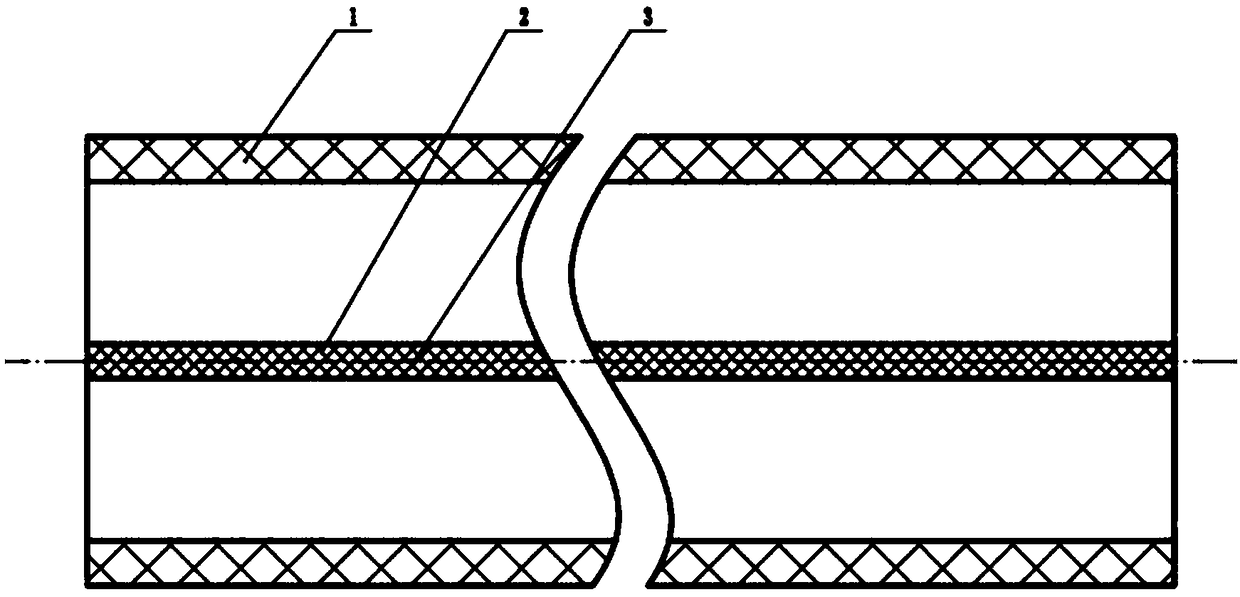

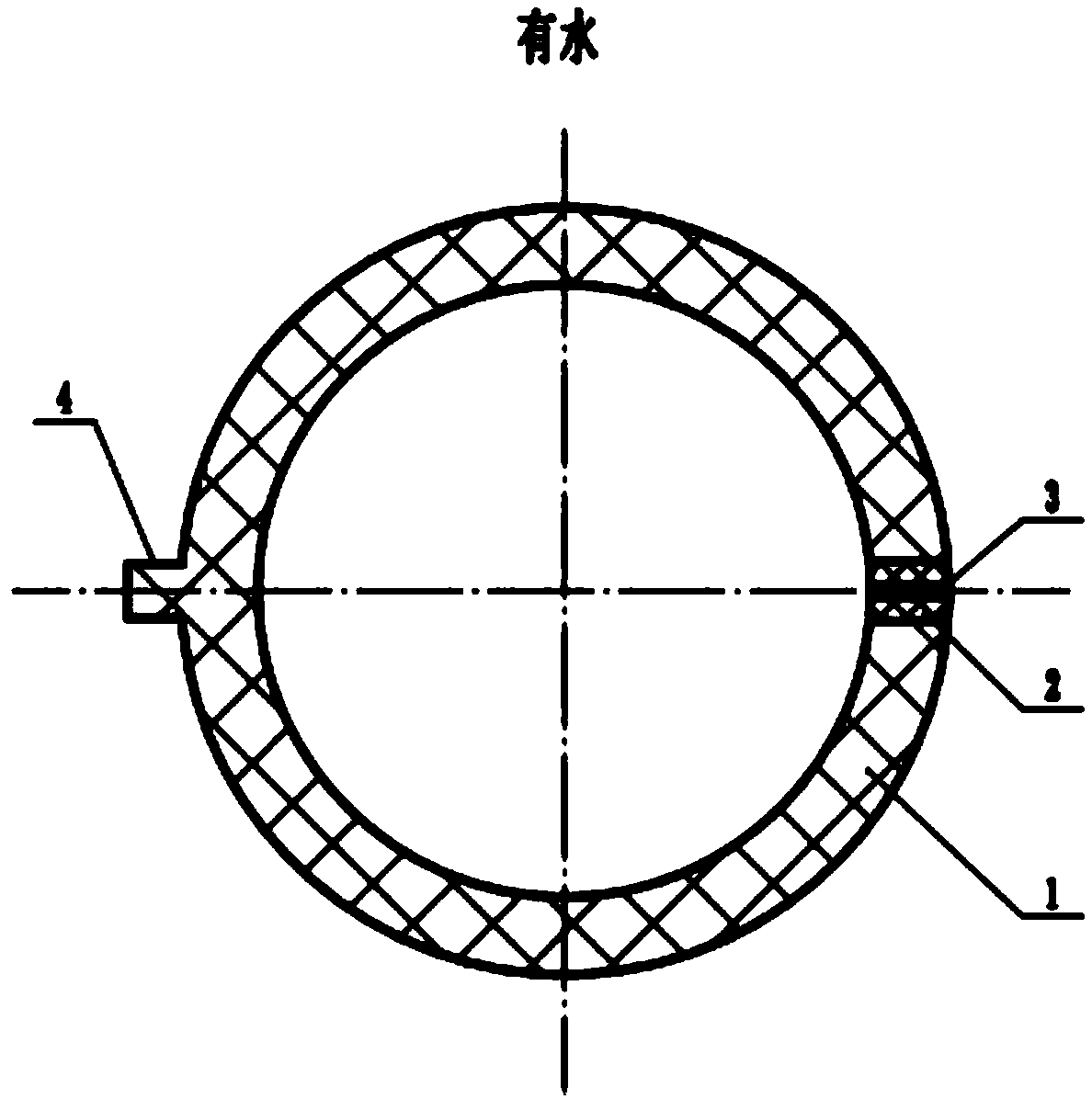

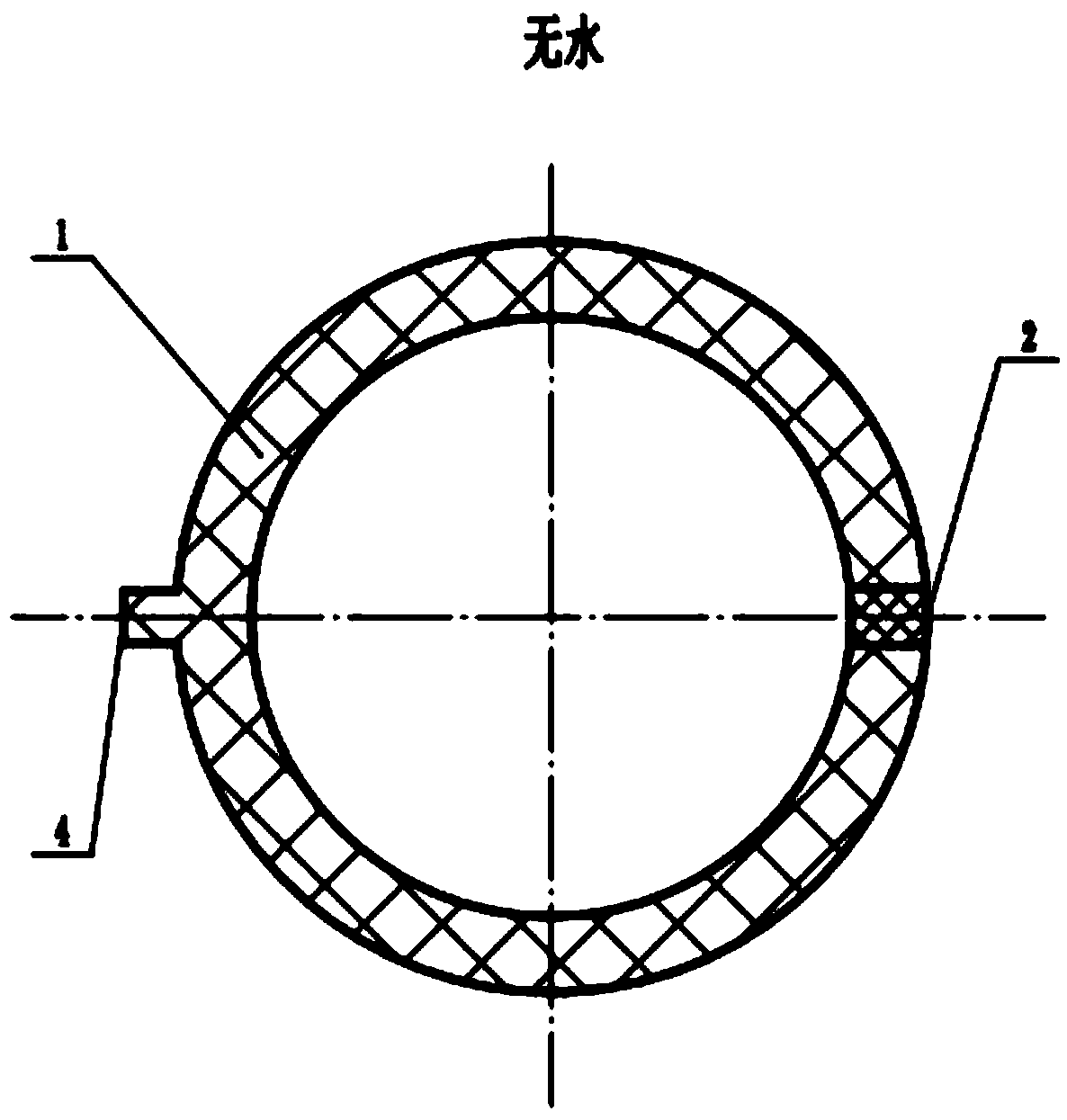

[0025] Such as figure 1 , image 3 As shown, an underground composite seepage pipe of the present invention includes a PP pipe (1), a polymer elastomer groove (2), a seepage hole (3), and a positioning seat (4). It is characterized in that: the PP pipe (1) is compositely connected with the polymer elastomer groove (2), and is extruded at the same time by an extruder; the polymer elastomer groove (2) is provided with water seepage holes (3) , the seepage holes (3) are distributed in the middle of the polymer elastomer groove (2), and the water seepage holes (3) are distributed along the axial direction of the PP pipe (1); the positioning seat (4) is located in the polymer elastomer groove (2) directly below, symmetrically distributed on the outside of the PP pipe (1) with the polymer elastomer groove (2), the polymer elastomer groove (2) is perpendicular to the ground plane and the seepage hole (3) faces the ground upwards, and the positioning seat ( 4) Perpendicular to groun...

example 2

[0027] Such as figure 1 , figure 2 As shown, an underground composite seepage pipe of the present invention includes a PP pipe (1), a polymer elastomer groove (2), a seepage hole (3), and a positioning seat (4). It is characterized in that: the PP pipe (1) is compositely connected with the polymer elastomer groove (2), and is extruded through an extruder at the same time to form; the polymer elastomer groove (2) has a water seepage hole (3) , the seepage holes (3) are distributed in the middle of the polymer elastomer groove (2), and the water seepage holes (3) are distributed along the axial direction of the PP pipe (1); the positioning seat (4) is located in the polymer elastomer groove (2) directly below, symmetrically distributed on the outside of the PP pipe (1) with the polymer elastomer groove (2), the polymer elastomer groove (2) is perpendicular to the ground plane and the seepage hole (3) faces the ground upwards, and the positioning seat ( 4) Perpendicular to gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com