Hydrogen eliminating agent, preparation method thereof, and aluminum electrolytic capacitor electrolyte

A hydrogen elimination agent and solvent technology, which is applied in the field of electrochemical capacitor electrolyte, can solve the problems of poor solubility, flash fire voltage influence, etc., and achieve excellent hydrogen elimination effect, good stability, and excellent solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

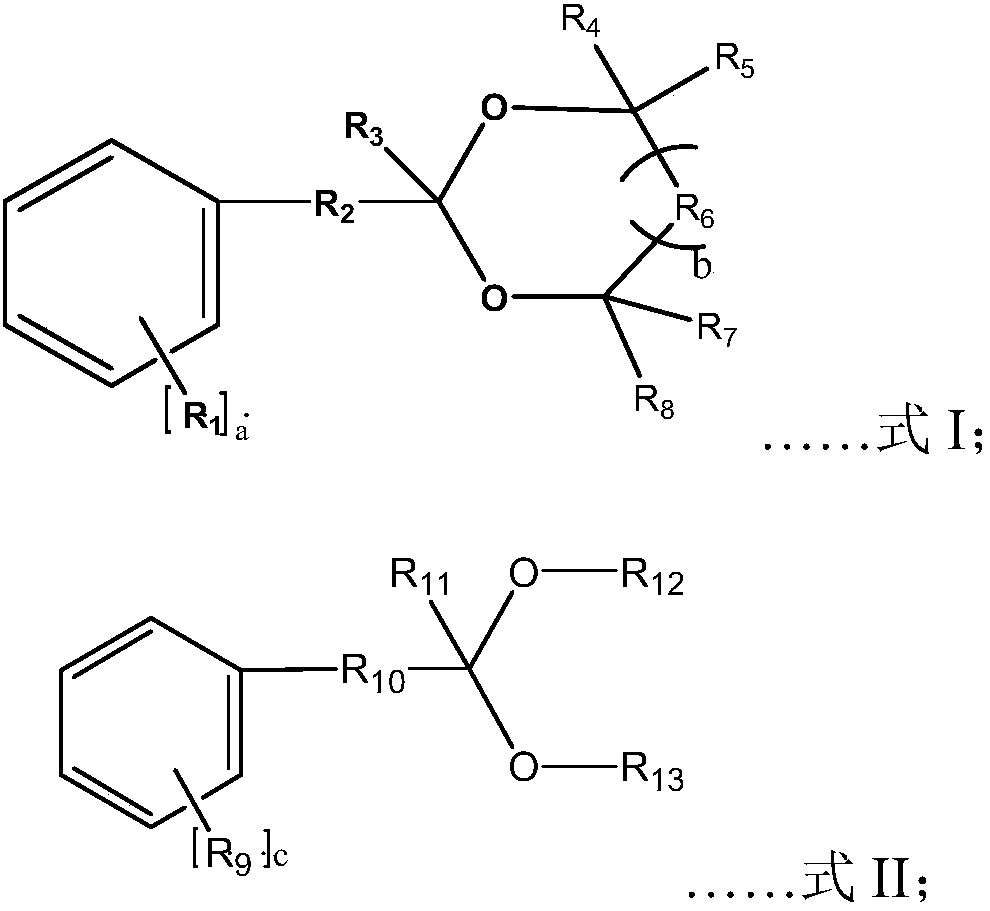

Image

Examples

preparation example Construction

[0083] The preparation method of described hydrogen remover comprises the following steps at least:

[0084] In the presence of a catalyst, the first reaction raw material and the second reaction raw material are added to the solvent, and the reaction is carried out at 60°C to 160°C;

[0085] Subsequently, the solvent is removed, and the reaction product containing the hydrogen suppressant is obtained through cooling and separation;

[0086] Wherein, the structural formula of the first reaction raw material is shown in formula IV,

[0087] (R 14 ) m -Ph-R 15 COR 16 ...Formula IV;

[0088] Among them, R 14 for nitro, R 15 An organic group selected from 0 to 5 carbon atoms; R 16 An organic group with 1 to 5 carbon atoms; m=1 or 2;

[0089] The second reaction raw material is polyhydric alcohol.

[0090] Next, the above preparation method will be further explained.

[0091] Specifically, the preparation route of the hydrogen remover of the present invention is as follo...

Embodiment 1

[0111] A preparation method of a hydrogen remover for aluminum electrolytic capacitors, comprising the following steps:

[0112] Weigh 60g of xylene, 44.6g (0.2mol) of 2,4-dinitropropiophenone, and 13.6g (0.22mol) of ethylene glycol into a 250ml three-neck flask, stir well and add 1.7g of p-toluenesulfonic acid (0.01mol), add a reflux dewatering device at the mouth of the flask, and heat to 110°C for reflux reaction for 5h;

[0113] Solvent was distilled off after completion;

[0114] The reaction product was distilled under reduced pressure, and the resulting product was 47g. After sampling and detection, the product was mainly 2-methyl-2-(2-nitrotoluene)-1,3-dioxolane, which was denoted as S1, and the total The yield is about 88%.

Embodiment 2

[0116] A preparation method of a hydrogen remover for aluminum electrolytic capacitors, comprising the following steps:

[0117] Weigh 60g of xylene, 33g (0.2mol) of 4-nitroacetophenone, and 16.7g (0.22mol) of 1,3-propanediol and add them to a 250ml three-neck flask, stir well and add 4g (0.01mol) of iron sulfate, Add a reflux dewatering device at the mouth of the flask, and heat to 120°C for reflux reaction for 6 hours;

[0118] Solvent was distilled off after completion;

[0119] The reactant was stirred and cooled to room temperature, and filtered out after the solid precipitated to the maximum;

[0120] The filtrate was stirred in a suitable solvent for extraction and layered, the extractant was separated and removed, washed with pure water for 3 times, and dried to remove water to obtain 40 g of the product.

[0121] After sampling and detection, the product is mainly 2-methyl-2-(4-nitrobenzene)-1,3-dioxane, which is denoted as S2, and the total yield is about 89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com