Automatic dry-wet freeze-thaw cycling test device and test method

A freeze-thaw cycle and test device technology, which is used in measuring devices, soil material testing, material inspection products, etc. Realize the effect of fully automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

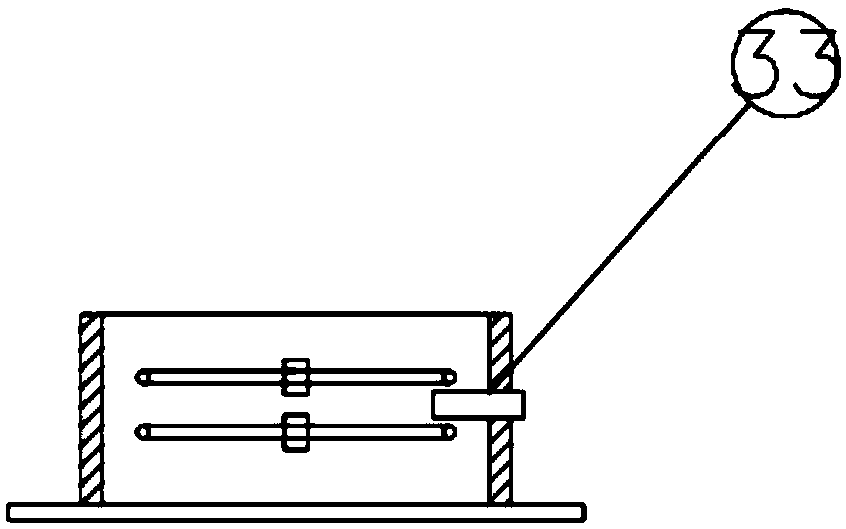

[0036] like Figure 1-7As shown, the invention discloses a loess dry-wet freeze-thaw cycle test device and test method. The test device includes an operation table, a control module, an evaporation module, a spray module, a weighing module, a refrigeration module, and a manipulator operation module. The evaporation module, the spray module, the weighing module, the refrigeration module and the manipulator operation module are arranged on the operation table. The evaporation module detects the temperature through the temperature sensor and sends the signal to the intelligent temperature control instrument to complete the temperature control; the spray module controls the peristaltic pump through the pulse sent by the control module to complete the control of the water addition; the weighing module detects the temperature through the pressure se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com