Laminated water-cooling radiator

A water-cooled radiator and layered technology, which is applied in the types of heat exchangers, indirect heat exchangers, laminated components, etc., can solve the problems of cumbersome manufacturing process, and achieve the advantages of simple manufacturing process, large contact area and good water cooling effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

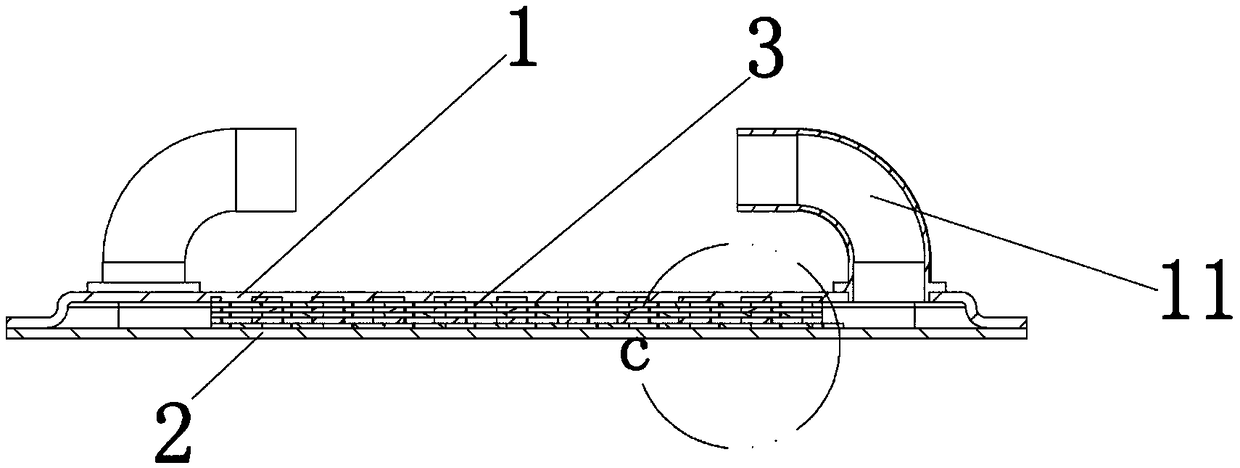

[0037] Embodiment 1 of the present invention provides a laminated water-cooled radiator, such as Figure 1-5 As shown, it includes a cover plate 1, a bottom plate 2, and a laminated water-cooled plate 3;

[0038] The cover plate 1 is arranged on the top of the laminated water-cooled plate 3 stacked symmetrically and has at least one water inlet 11;

[0039] The bottom plate 2 is arranged at the bottom of the laminated water-cooled plate 3 that is stacked in multiple layers symmetrically and is provided with a water outlet 21;

[0040] The laminated water-cooling plate 3 is symmetrically stacked in multiple layers and located between the cover plate 1 and the bottom plate 2, and the openings on the symmetrically stacked laminated water-cooling plate 3 form a water flow channel.

[0041] Specifically, at least two laminated water cooling plates 3 are stacked.

[0042] The laminated water cooling plate 3 of each layer is a rectangular plate, and the openings on the laminated wa...

Embodiment 2

[0048] Embodiment 2 of the present invention provides a laminated water-cooled radiator, such as Figure 6-12 As shown, it includes a cover plate 1, a bottom plate 2, and a laminated water-cooled plate 3;

[0049] The cover plate 1 is arranged on the top of the laminated water-cooled plate 3 stacked symmetrically and has at least one water inlet 11;

[0050] The bottom plate 2 is arranged at the bottom of the laminated water-cooled plate 3 that is stacked in multiple layers symmetrically and is provided with a water outlet 21;

[0051] The laminated water-cooling plate 3 is symmetrically stacked in multiple layers and located between the cover plate 1 and the bottom plate 2, and the openings on the symmetrically stacked laminated water-cooling plate 3 form a water flow channel.

[0052] Specifically, at least two laminated water cooling plates 3 are stacked.

[0053] The laminated water-cooling plate 3 of each layer is a circular plate, and the center of each layer of the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com