Pneumatic actuator control high pressure ball valve

A technology of pneumatic actuators and high-pressure ball valves, applied in the field of high-pressure ball valves and ball valves, can solve the problems of high maintenance costs and inconvenient operation, and achieve the effects of small fluid resistance, long service life and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

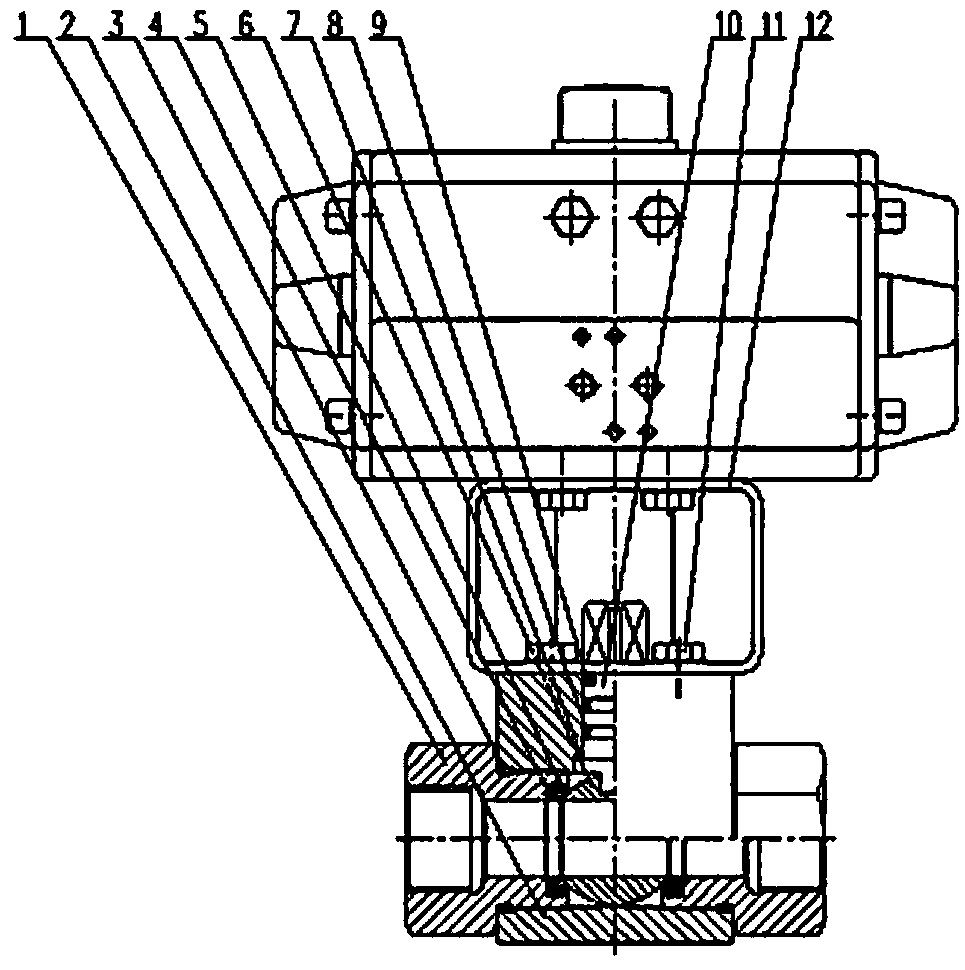

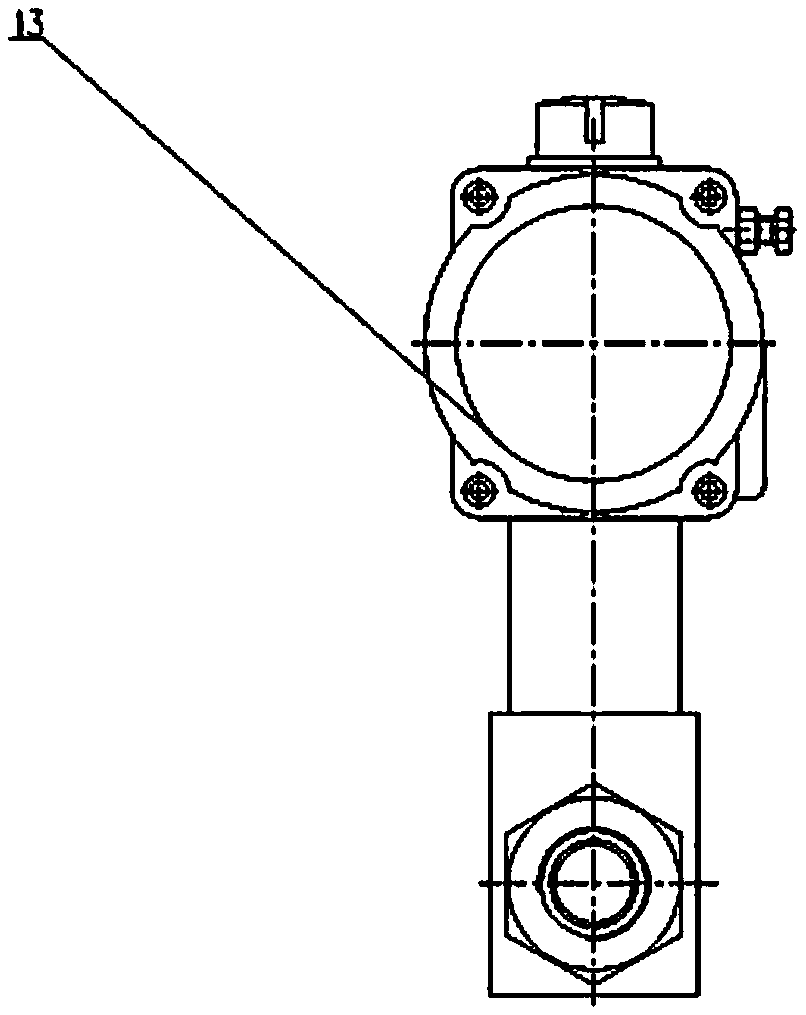

[0012] As shown in the figure, 1. Lower connection joint, 2. Valve body, 3. O-ring, 4. Adjusting butterfly spring, 5. Enhanced PPL synthetic sealing material, 5. O-ring, 6. Ball valve core, 7. Gasket, 8. O-ring, 9. Packing, 10. Valve stem, 11. Hex bolt, 12. Bracket, 13. Pneumatic control device.

[0013] A pneumatic actuator controls a high-pressure ball valve. The valve body is a horizontal thick cylindrical cylinder. The lower part of the ball valve core can be connected with a convex post, and a concave ball arc is prepared with a cylindrical hole matching the convex post.

[0014] The valve body, upper cover and ball seat sealing ring are all made of block cast steel, and are fixed with hexagon socket head screws.

[0015] The thick cylinder and the whole cylinder adopt a forged structure to ensure the overall strength of the valve body. The length of the entire ball valve is only 1 / 2 of that of the ordinary globe valve; the combination structure of reinforced PPL syntheti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com