Layered acidification and layered water injection measurement and adjustment integrated multi-functional pipe column

A layered water injection and multi-functional technology, applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problem of poor effect of layered acidification and layered water injection, lack of flow testing and deployment, and technical solutions same problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

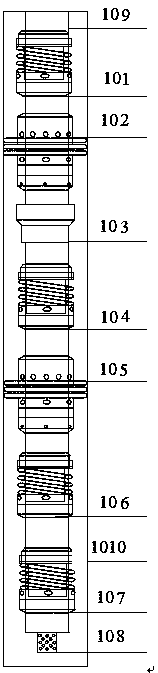

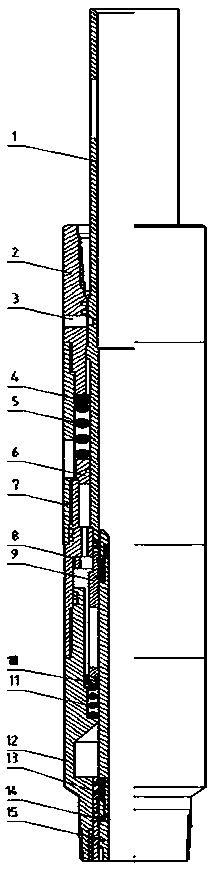

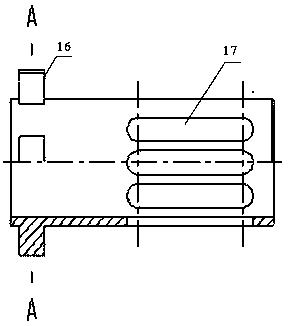

[0028] as attached Figure 1 to Figure 4 As shown in the figure, the multi-functional pipe string integrated with layered acidification and layered water injection measurement and adjustment, the oil pipe is equipped with an integrated water distributor for acidification measurement and adjustment 101, an upper washable well packer 102, and an integrated water distributor for lower acidification measurement and adjustment 104. The lower washable well packer 105, wherein the upper washable well packer 102 and the lower washable well packer 105 are respectively located in the upper acidizing integrated water distributor 101 and the lower acidified integrated water distributor 104 position below.

[0029] A limiting sealing device 103 is also arranged on the oil pipe, and the limiting sealing device 103 is located between the upper washable well packer 102 and the lower integrated water distributor 104 for acidification measurement and adjustment.

[0030] The oil pipe is also p...

Embodiment 2

[0043] as attached Figure 1 to Figure 4 As shown, the multifunctional pipe string integrated with layered acidification and layered water injection measurement and adjustment, the oil pipe is equipped with an integrated water distributor for acidification measurement and adjustment 1, an upper washable well packer 2, and an integrated water distributor for lower acidification measurement and adjustment 4. The lower flushable packer 5, wherein the upper flushable packer 2 and the lower flushable packer 5 are respectively located in the upper integrated water distributor for acidification measurement and regulation 1 and the lower integrated water distributor for acidification measurement and regulation 4 position below. The oil pipe is also provided with a setting and acidizing integrated water distributor 7 , and the setting and acidizing integrated water distributor 7 is located below the lower flushable packer 5 . The oil pipe is also provided with an integrated water dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com